Silica airgel with high specific surface area and rapid preparation method thereof

A high specific surface area, silicon dioxide technology, applied in the direction of silicon dioxide, silicon oxide, chemical instruments and methods, etc., can solve the problems of unstable product quality, easy volatilization, collapse and rupture of nanopores, etc., to overcome the reaction rate Inhibited, less solvent volatilization loss, avoiding collapse and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

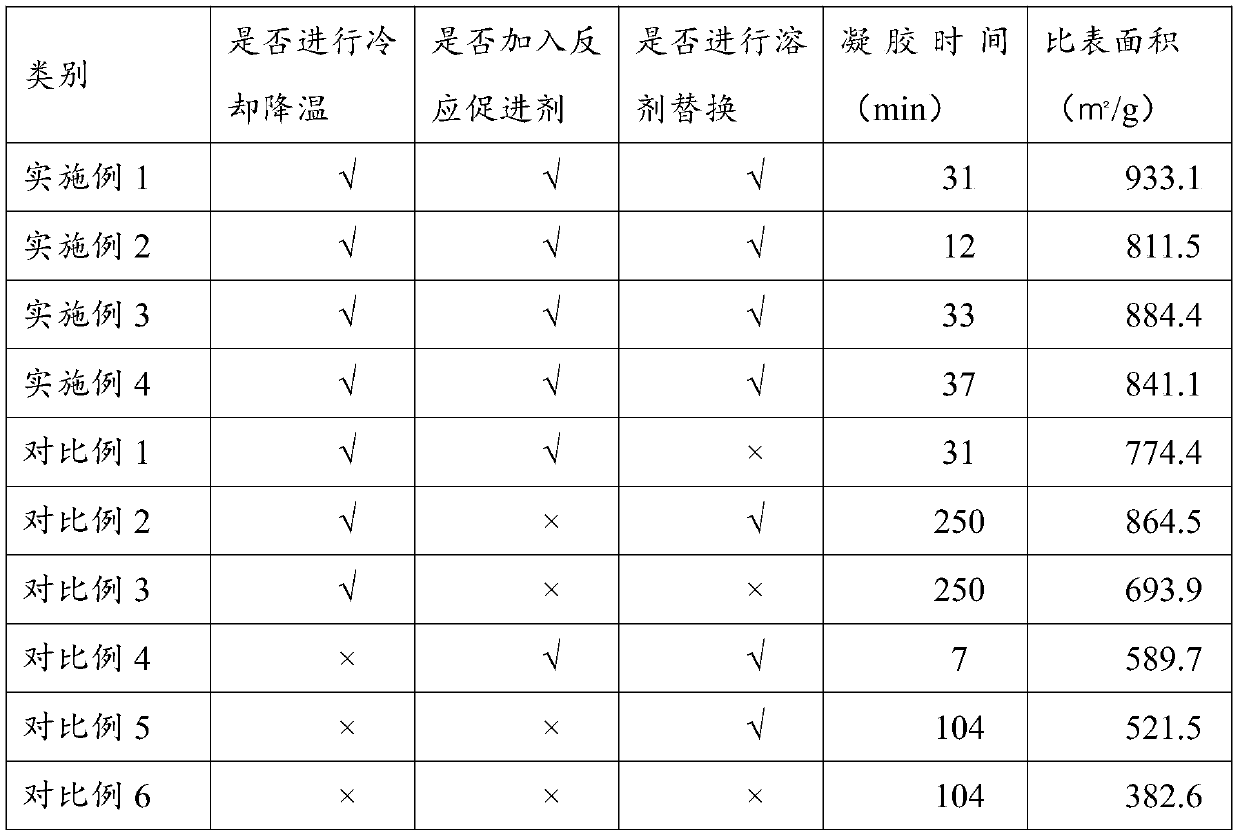

Examples

Embodiment 1

[0027] The method for rapidly preparing high specific surface area silica airgel of the present embodiment comprises the following steps:

[0028] (1) Cool ethyl orthosilicate, absolute ethanol, oxalic acid, ammonia, water, and n-hexane to 5°C;

[0029] (2) Mix ethyl orthosilicate, absolute ethanol, oxalic acid, and water in a constant temperature reactor at 5°C, then add ammonia water and n-hexane to mix, then let the gel stand, record the gel time, and age at 5°C for 8 hours ; The molar ratio of tetraethyl orthosilicate, absolute ethanol, oxalic acid, water, ammonia water and n-hexane is 1:18:0.005:4:0.005:0.2;

[0030] (3) Transfer the aged gel into ethylene glycol dimethyl ether, and change the liquid at 25° C. for 2 hours;

[0031] (4) Perform supercritical drying on the gel after solvent exchange, and dry it with supercritical carbon dioxide at 70° C. and 19 MPa for 6 hours to obtain silica airgel, and measure its specific surface area.

Embodiment 2

[0033] The method for rapidly preparing high specific surface area silica airgel of the present embodiment comprises the following steps:

[0034] (1) Cool ethyl orthosilicate, absolute ethanol, oxalic acid, ammonia, water, and n-hexane to 5°C;

[0035] (2) Mix ethyl orthosilicate, absolute ethanol, oxalic acid, and water in a constant temperature reactor at 5°C, then add ammonia water and n-hexane to mix, then let the gel stand, record the gel time, and age at 5°C for 8 hours ; The molar ratio of tetraethyl orthosilicate, absolute ethanol, oxalic acid, water, ammonia water and n-hexane is 1:18:0.005:4:0.005:0.5;

[0036] (3) Transfer the aged gel into ethylene glycol dimethyl ether, and change the liquid at 25° C. for 2 hours;

[0037] (4) Perform supercritical drying on the gel after solvent exchange, and dry it with supercritical carbon dioxide at 70° C. and 19 MPa for 6 hours to obtain silica airgel, and measure its specific surface area.

Embodiment 3

[0039] The method for rapidly preparing high specific surface area silica airgel of the present embodiment comprises the following steps:

[0040] (1) Cool tetraethyl orthosilicate, methanol, nitric acid, ammonium carbonate buffer, water, and n-hexane to 1°C;

[0041] (2) Mix ethyl orthosilicate, methanol, nitric acid, and water in a constant temperature reactor at 1°C, then add ammonium carbonate buffer and n-hexane to mix, then let the gel stand, record the gel time, and age at 1°C 8h; the molar ratio of ethyl orthosilicate, absolute ethanol, nitric acid, water, ammonium carbonate buffer and n-hexane is 1:20:0.01:2:0.01:0.3;

[0042] (3) Transfer the aged gel into ethylene glycol dimethyl ether, and change the liquid at 15° C. for 3 hours;

[0043] (4) Perform supercritical drying on the gel after solvent exchange, and dry it with supercritical carbon dioxide at 70° C. and 19 MPa for 6 hours to obtain silica airgel, and measure its specific surface area.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com