Method for preparing propylene from n-butene

A technology for n-butene and propylene, which is applied in chemical instruments and methods, hydrocarbon cracking to produce hydrocarbons, molecular sieve catalysts, etc., can solve the problems that the yield of propylene needs to be further improved, the single-pass yield of the target product propylene is low, etc. high yield of propylene per pass, and the effect of enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

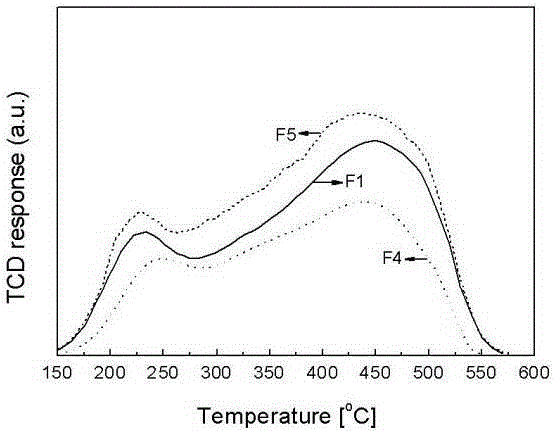

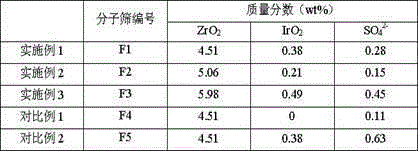

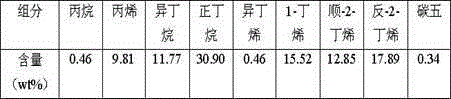

[0035] The specific preparation process of modified ZSM-5 molecular sieve F1 is as follows: (1) 8.5 g of zirconyl nitrate and 0.8 g of chloroiridic acid were dissolved in 22 ml of deionized water, and the obtained saline solution was added to 650 ml of n-hexane solvent, Stirring was continued for 1 hour to form a suspension A1. Add 114.5 g of Si / Al molar ratio 76, pore volume 0.19 cm to suspension A1 3 / g hydrogen ZSM-5 molecular sieve, stirred at room temperature (25°C) for 2 hours to obtain slurry B1. (2) Place the slurry B1 in a rotary evaporator, evaporate the n-hexane solvent to dryness, and obtain dry glue C1, dry at room temperature (25°C) for 24 hours, dry at 120°C for 12 hours, and then bake at 650°C for 5 hours, ZSM-5 molecular sieve D1 containing zirconium and iridium was obtained. (3) Transfer D1 into 500 ml of 0.1 mol / L ammonium sulfate solution and soak for 5 hours. After the required soaking time is reached, filter out the ammonium sulfate solution and rinse t...

Embodiment 2

[0039] The specific preparation process of modified ZSM-5 molecular sieve F2 is as follows: (1) 9.5 g of zirconyl nitrate and 0.5 g of chloroiridic acid were dissolved in 26 ml of deionized water, and the resulting saline solution was added to 520 ml of cyclohexane solvent , stirring continuously for 1 hour to form suspension A2. Add 113.0 g of Si / Al molar ratio 54, pore volume 0.23 cm to suspension A2 3 / g hydrogen ZSM-5 molecular sieve, stirred at room temperature (25°C) for 2 hours to obtain slurry B2. (2) Place the slurry B2 in a rotary evaporator and evaporate the cyclohexane solvent to obtain dry glue C2, dry it at room temperature (25°C) for 24 hours, dry it at 120°C for 12 hours, and then bake it at 600°C After 10 hours, ZSM-5 molecular sieve D2 containing zirconium and iridium was obtained. (3) Transfer D2 into 500 ml of 0.5 mol / L ammonium sulfate solution and soak for 1 hour. After the required soaking time is reached, filter out the ammonium sulfate solution and r...

Embodiment 3

[0041] The specific preparation process of modified ZSM-5 molecular sieve F3 is as follows: (1) 11.2 g of zirconyl nitrate and 1.1 g of chloroiridic acid were dissolved in 23.7 ml of deionized water, and the resulting saline solution was added to 950 ml of cyclohexane solvent , stirring continuously for 1 hour to form suspension A3. Add 114.5 g of Si / Al molar ratio 93, pore volume 0.21 cm to suspension A3 3 / g hydrogen ZSM-5 molecular sieve, stirred at room temperature (25°C) for 2 hours to obtain slurry B3. (2) Place the slurry B3 in a rotary evaporator and evaporate the cyclohexane solvent to obtain dry glue C3, dry at room temperature (25°C) for 24 hours, dry at 120°C for 12 hours, and then bake at 630°C After 10 hours, ZSM-5 molecular sieve D3 containing zirconium and iridium was obtained. (3) Transfer D3 into 500 ml of 0.3 mol / L sulfuric acid solution and soak for 3 hours. After the required soaking time is reached, filter out the sulfuric acid solution and rinse the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com