Method for preparing bifunctional catalyst from peanut hull

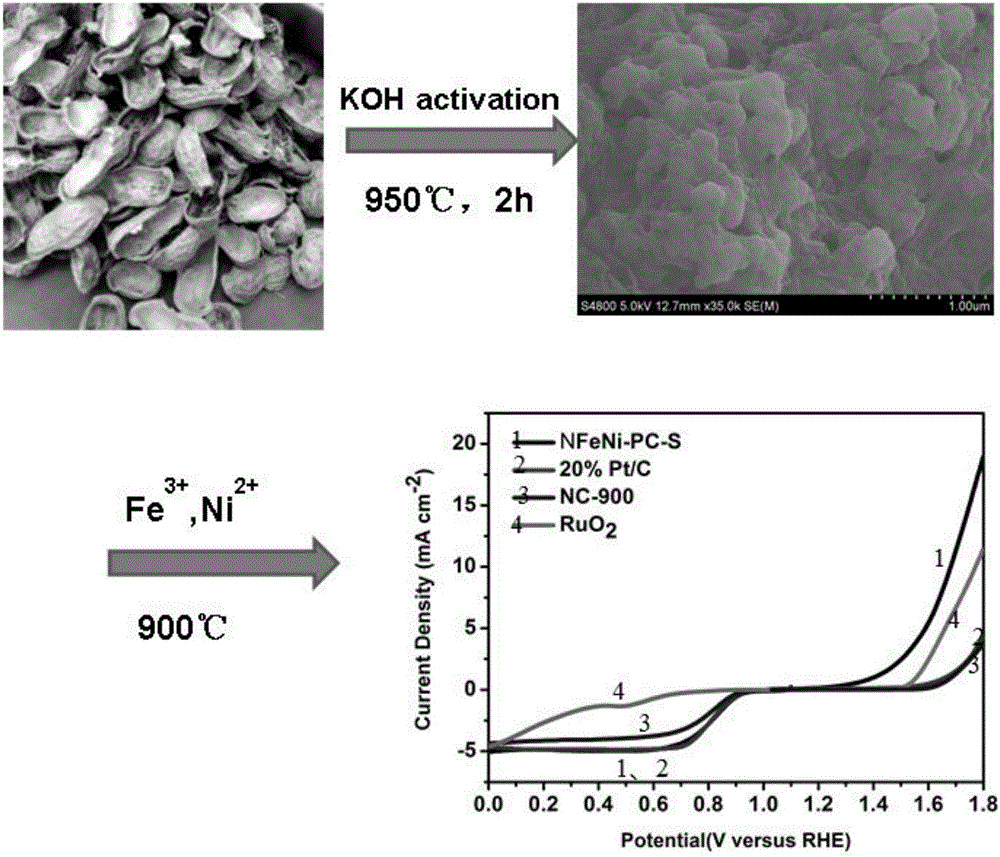

A bifunctional catalyst and peanut shell technology, which is applied in the field of electrocatalysis, can solve the problems of hindering the commercial application of hydrogen production by electrolysis, high price, and scarcity of substances, and achieve the effects of promoting electrocatalytic performance, low cost and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: A method for preparing a bifunctional electrocatalyst using biomass peanut shells as a raw material

[0046] 1) Peanut shells are ground and crushed with a grinder, 6g of peanut shells are weighed, dissolved in 80ml of water, ultrasonicated for 30 minutes, and stirred for 2 hours.

[0047] 2) Transfer the solution to a 100ml reaction kettle and heat at 150°C for 30 hours.

[0048] 3) Take out the carbon airgel in the reaction kettle, filter, wash with water several times, and dry. Take 1 g of filter cake and transfer it to a beaker, add 1 g of potassium hydroxide, 60 ml of water, 2 g of glucose, and 2 g of melamine, magnetically stir for 12 hours, dry, and record as powder 1.

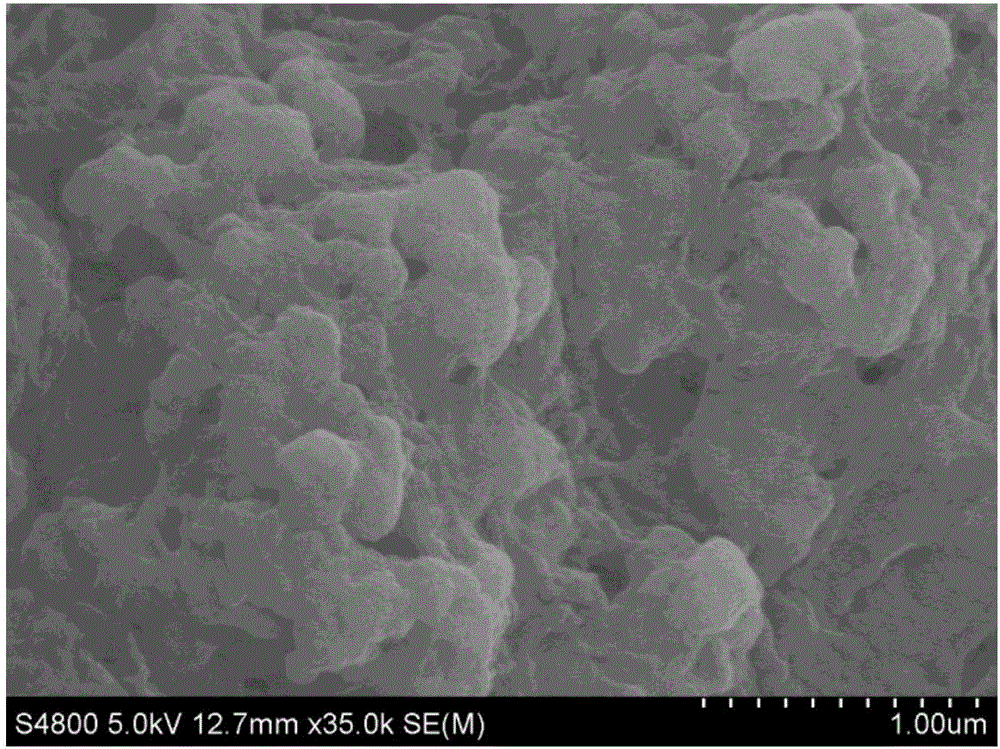

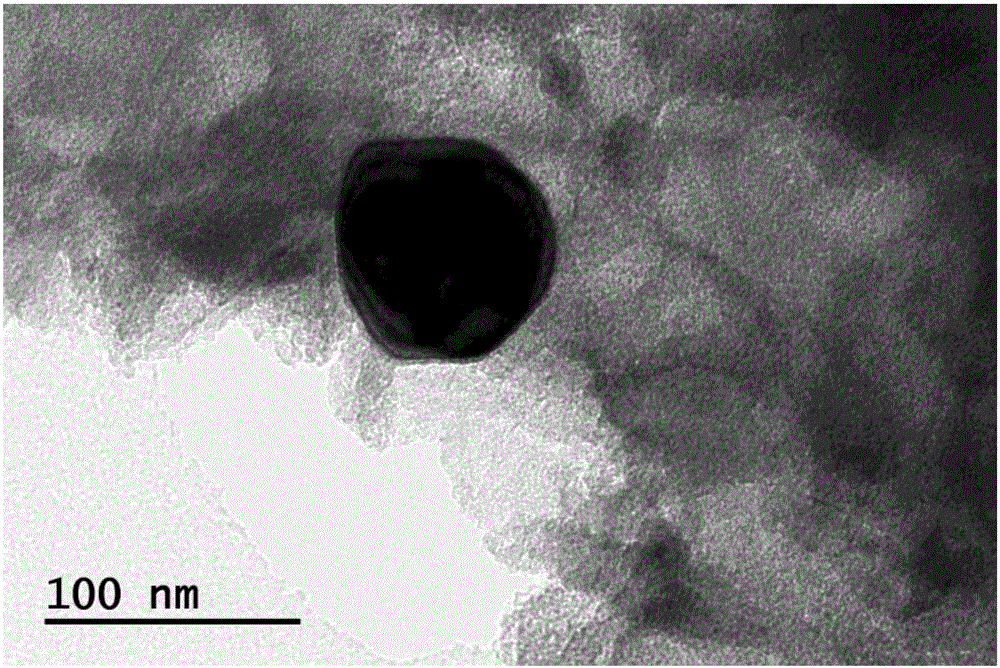

[0049] 4) Put powder 1 into a tube furnace for carbonization, the temperature rises to 950°C (increase at a rate of 2°C per minute, keep at 200°C for 2 hours, and keep at 950°C for 2 hours), soak in 1M HCl 5ml for 12 hours, filter, Rinse with a large amount of water until PH=7, recor...

Embodiment 2

[0052] Example 2: A method for preparing a bifunctional electrocatalyst using biomass peanut shells as a raw material

[0053] 1) Peanut shells are ground and crushed with a grinder, 6g of peanut shells are weighed, dissolved in 80ml of water, ultrasonicated for 30 minutes, and stirred for 2 hours.

[0054] 2) Transfer the solution to a 100ml reaction kettle and heat at 150°C for 30 hours.

[0055] 3) Take out the carbon airgel in the reaction kettle, filter, wash with water several times, and dry. Take 1 g of filter cake and transfer it to a beaker, add 1 g of potassium hydroxide, 60 ml of water, 2 g of glucose, and 2 g of melamine, magnetically stir for 12 hours, dry, and record as powder 1.

[0056] 4) Put powder 1 into a tube furnace for carbonization, the temperature rises to 950°C (increase at a rate of 2°C per minute, keep at 200°C for 2 hours, and keep at 950°C for 2 hours), soak in 1M HCl 5ml for 12 hours, filter, Rinse with a large amount of water until PH=7, recor...

Embodiment 3

[0059] Example 3: A method for preparing a bifunctional electrocatalyst using biomass peanut shells as a raw material

[0060] 1) Peanut shells are ground and crushed with a grinder, 6g of peanut shells are weighed, dissolved in 80ml of water, ultrasonicated for 30 minutes, and stirred for 2 hours.

[0061] 2) Transfer the solution to a 100ml reaction kettle and heat at 150°C for 30 hours.

[0062] 3) Take out the carbon airgel in the reaction kettle, filter, wash with water several times, and dry. Take 1 g of filter cake and transfer it to a beaker, add 1 g of potassium hydroxide, 60 ml of water, 2 g of glucose, and 2 g of melamine, magnetically stir for 12 hours, dry, and record as powder 1.

[0063] 4) Put powder 1 into a tube furnace for carbonization, the temperature rises to 950°C (increase at a rate of 2°C per minute, keep at 200°C for 2 hours, and keep at 950°C for 2 hours), soak in 1M HCl 5ml for 12 hours, filter, Rinse with a large amount of water until PH=7, recor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com