Simple preparation method of high-dispersion nickel oxide cluster modified carbon nitride photocatalyst for decomposing water to produce hydrogen

A photocatalyst, high dispersion technology, applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc., can solve special problems, complex methods, etc., to achieve increased hydrogen production, simple preparation process, excellent photocatalysis performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

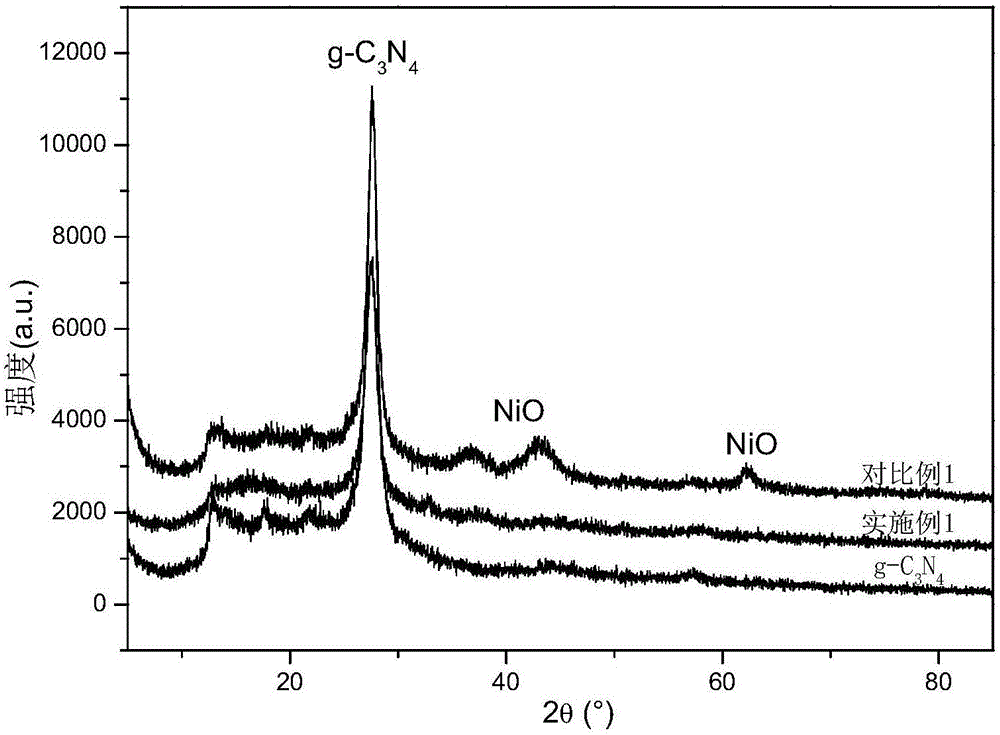

[0027] According to the loading amount of NiO in the photocatalyst is 9%, 1.0g g-C 3 N 4 , 0.288g of nickel chloride hexahydrate, 70.0g of deionized water were added to the beaker, then ammonia water was added to adjust the pH value to 11, stirred at room temperature for 8 hours and then allowed to stand for 6 hours, then all the water was evaporated to dryness at 100°C, and then Calcined at 300°C for 3 hours to obtain highly dispersed nickel-oxygen cluster-modified two-dimensional carbon nitride photocatalyst.

Embodiment 2~7

[0032] According to the method of Example 1, two-dimensional carbon nitride photocatalysts modified with highly dispersed nickel-oxygen clusters with NiO loadings of 0.5%, 1%, 3%, 5%, 7%, and 10% were sequentially prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com