Preparation method of visible-light-induced photocatalyst with core-shell structure

A core-shell structure and catalyst technology, applied in the field of photocatalysis, can solve the problems of limited catalytic efficiency, complicated preparation process of visible light catalyst, etc., and achieve the effect of energy saving of the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

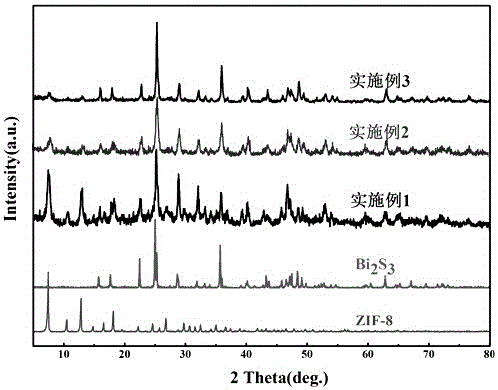

Embodiment 1

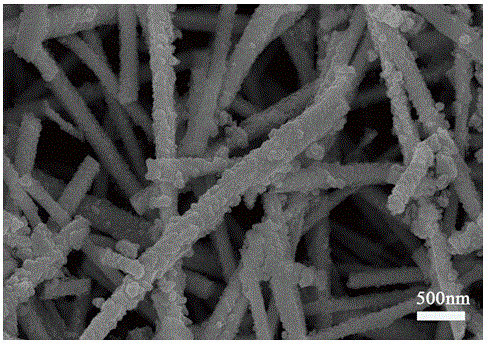

[0024] (1) Bi 2 S 3Preparation of nanowires

[0025] a. Weigh bismuth nitrate, thiourea, lithium hydroxide, polyvinylpyrrolidone (PVP), and ethylene glycol in proportions of 1 mmol: 3 mmol: 3 g: 1 mmol: 10 ml;

[0026] b. put the material weighed in step a into the reactor, and react at 200 ° C for 24 h;

[0027] c. Filter the mixture obtained in b, wash, and vacuum-dry at 80 °C for 6 h to obtain Bi 2 S 3 Nanowires.

[0028] (2) ZIF-8@Bi 2 S 3 Self-assembly of nanowires:

[0029] a. Weigh 17.5mmolZn(NO 3 ) 2 •6H 2 O was dispersed in 15 ml of methanol solution, ultrasonicated for 10 min, and left to stand to form a stable aqueous alcohol solution;

[0030] b. Weigh 0.35mmol Bi from (1) 2 S 3 Nanowires, soaked in a solution, stirred for 5h, then filtered and washed to promote Bi 2 S 3 Nanowires assemble to form Zn through S-Zn coupling bond energy 2+ @Bi 2 S 3 Composite structure;

[0031] c. Weigh 35mmol 2-methylimidazole and disperse in 15ml methanol solutio...

Embodiment 2

[0035] (1) Bi 2 S 3 Preparation of nanowires

[0036] a. Weigh bismuth nitrate, thiourea, lithium hydroxide, polyvinylpyrrolidone (PVP), and ethylene glycol in proportions of 1 mmol: 3 mmol: 3 g: 1 mmol: 10 ml;

[0037] b. put the material weighed in step a into the reactor, and react at 200 ° C for 24 h;

[0038] c. Filter the mixture obtained in b, wash, and vacuum-dry at 80 °C for 6 h to obtain Bi 2 S 3 Nanowires.

[0039] (2) ZIF-8@Bi 2 S 3 Self-assembly of nanowires:

[0040] a. Weigh 7mmolZn(NO 3 ) 2 •6H 2 O was dispersed in 15 ml of methanol solution, ultrasonicated for 10 min, and left to stand to form a stable aqueous alcohol solution;

[0041] b. Weigh 0.35mmol Bi from (1) 2 S 3 Nanowires, soaked in a solution, stirred for 5h, then filtered and washed to promote Bi 2 S 3 Nanowires assemble to form Zn through S-Zn coupling bond energy 2+ @Bi 2 S 3 Composite structure;

[0042] c. Weigh 14 mmol 2-methylimidazole and disperse it in 15 ml of methanol s...

Embodiment 3

[0046] (1) Bi 2 S 3 Preparation of nanowires

[0047] a. Weigh bismuth nitrate, thiourea, lithium hydroxide, polyvinylpyrrolidone (PVP), and ethylene glycol in proportions of 1 mmol: 3 mmol: 3 g: 1 mmol: 10 ml;

[0048] b. put the material weighed in step a into the reactor, and react at 200 ° C for 24 h;

[0049] c. Filter the mixture obtained in b, wash, and vacuum-dry at 80 °C for 6 h to obtain Bi 2 S 3 Nanowires.

[0050] (2) ZIF-8@Bi 2 S 3 Self-assembly of nanowires:

[0051] a. Weigh 5mmolZn(NO 3 ) 2 •6H 2 O was dispersed in 15 ml of methanol solution, ultrasonicated for 10 min, and left to stand to form a stable aqueous alcohol solution;

[0052] b. Weigh 0.35mmol Bi from (1) 2 S 3 Nanowires, soaked in a solution, stirred for 5h, then filtered and washed to promote Bi 2 S 3 Nanowires assemble to form Zn through S-Zn coupling bond energy 2+ @Bi 2 S 3 Composite structure;

[0053] c. Weigh 10mmol 2-methylimidazole and disperse in 15ml methanol solution,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com