A kind of bacterial strain used for producing succinic acid by fermentation of biodiesel by-product crude glycerol and production method thereof

A technology for producing succinic acid and biodiesel, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, fermentation, etc., can solve the problem of high cost of raw materials, and achieve the effect of simple production method, reduction of production cost, and extension of industrial chain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

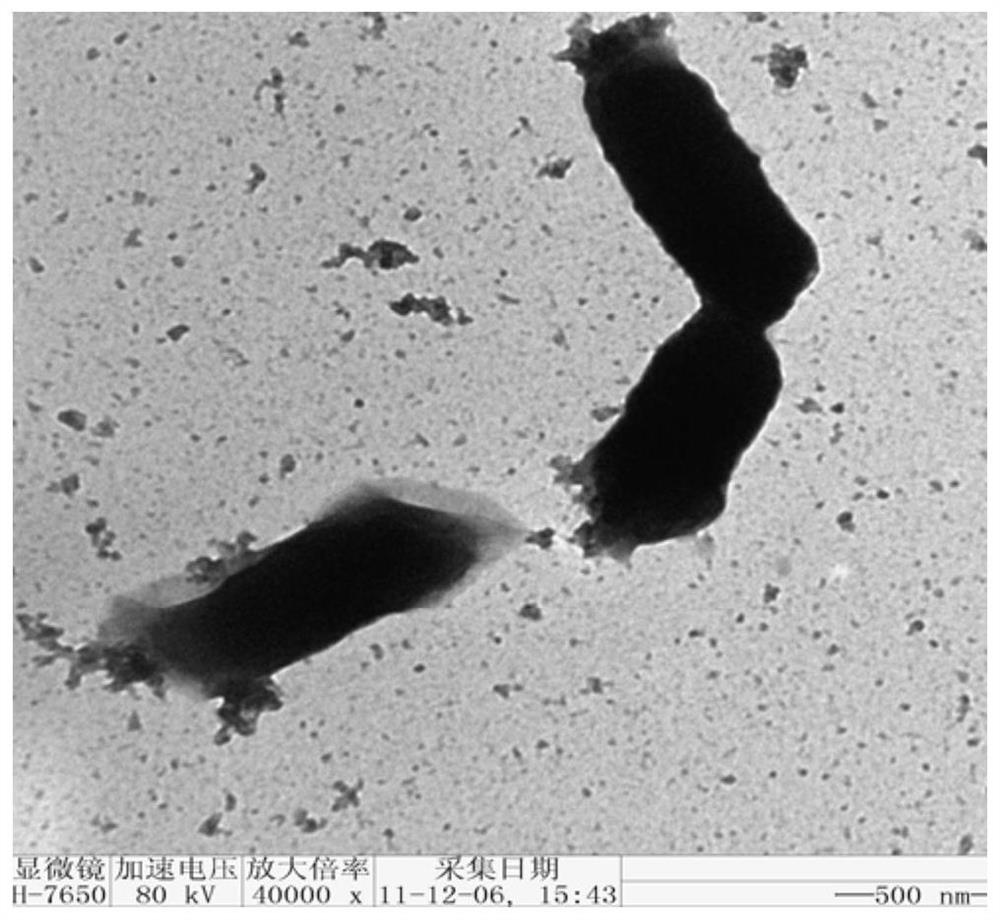

[0029] Breeding and identification of Actinobacillus succinate

[0030] 1. The method of directed evolution breeding of Actinobacillus succinogenes is as follows: first use 10g / L glycerol to replace the glucose in the seed solution as a carbon source as a directed medium, place it in an anaerobic incubator after inoculation, and keep it at 37°C Cultivate for 12-18 hours for subculture. After 7-10 days of cultivation, the concentration of glycerol increases to 20g / L, and so on. After about 90 days of domestication, the concentration of glycerol in the medium can be increased to 80g / L. XT, the strain can grow well in the culture set with a glycerol concentration of 80g / L.

[0031] 2. The 16S rDNA gene identification of the Actinobacillus succinogenes XT obtained from the above selection, and the physiological and biochemical identification according to the "Berger's Bacteria Identification Manual", the results are as follows:

[0032] Actinobacillus succinogenes XT is 100% simila...

Embodiment 2

[0035] Using Actinobacillus succinogenes CCTCC NO: M2016397 to ferment biodiesel by-product crude glycerol to produce succinic acid, the steps are as follows:

[0036] (1) Preparation of seed medium: Mix the ingredients with the following concentrations and sterilize at 115°C for 20 minutes to obtain the seed medium: glucose 20g / L, yeast powder 10g / L, corn steep liquor 4g / L, NaHCO 3 4g / L, NaH 2 PO 4 9.6g / L, K 2 HPO 4 1.55g / L.

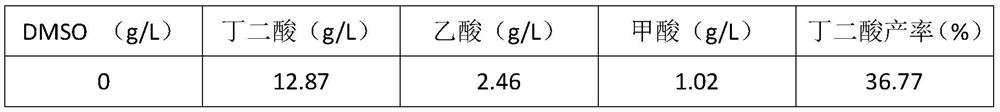

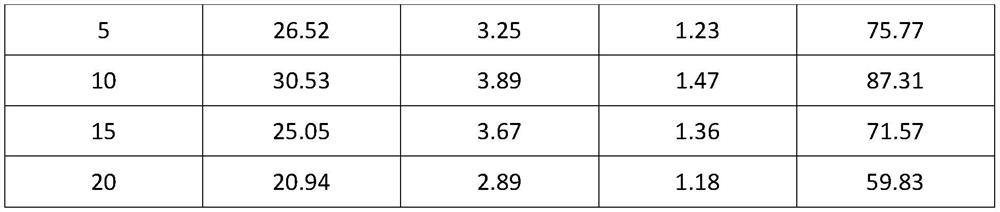

[0037] (2) Preparation of fermentation medium: Mix the ingredients with the following concentrations and sterilize at 115°C for 20 minutes to obtain a fermentation medium: crude glycerol 30g / L, nitrogen source 5g / L, potassium dihydrogen phosphate 2g / L, dihydrogen phosphate Methyl sulfoxide 0g / L, sodium bicarbonate 2g / L, calcium chloride 0.3g / L, magnesium chloride 0.3g / L.

[0038] The above-mentioned nitrogen source is corn steep liquor, yeast powder, soybean powder, and peanut cake powder mixed in any proportion.

[0039] The above-mentioned pH ...

Embodiment 3

[0049] Using Actinobacillus succinogenes CCTCC NO: M2016397 to ferment biodiesel by-product crude glycerol to produce succinic acid, the steps are as follows:

[0050] (1) Preparation of seed medium: Mix the ingredients with the following concentrations and sterilize at 115°C for 20 minutes to obtain the seed medium: glucose 20g / L, yeast powder 10g / L, corn steep liquor 4g / L, NaHCO 3 4g / L, NaH 2 PO 4 9.6g / L, K 2 HPO 4 1.55g / L.

[0051] (2) Preparation of fermentation medium: Mix the ingredients with the following concentrations and sterilize at 115°C for 20 minutes to obtain a fermentation medium: crude glycerol 100g / L, nitrogen source 20g / L, potassium dihydrogen phosphate 10g / L, dihydrogen phosphate Methyl sulfoxide 20g / L, sodium bicarbonate 10g / L, calcium chloride 1.0g / L, magnesium chloride 1.0g / L.

[0052] The nitrogen source mentioned above is corn steep liquor and yeast powder mixed in any proportion.

[0053] The above-mentioned pH regulator is basic magnesium car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com