Method for preparing alcohol through high-concentration fermentation of secondary starch slurry and cassava

A starch slurry, high concentration technology, applied in fermentation, biofuel and other directions, can solve the problems of low production cost, high methanol content, high alcohol quality, and achieve the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Embodiment 1: A kind of method of preparing alcohol by high-concentration fermentation of cassava pulp and cassava.

[0066](1) The yeast strain is Saccharomyces cerevisiae (high temperature resistance), purchased from Angel Yeast Co., Ltd.

[0067] Under aseptic operation, the yeast strains were rehydrated in 37°C 4.5Bx dilute mash for 15 minutes, and then the temperature was lowered to 34°C for 1.5 hours.

[0068] (2) Using sterile water, dilute the liquid seed solution after rehydration and activation in step (1) by 10 times, and dilute it 8 times to obtain a dilution ratio of 1:10 8 The bacterial seed liquid; the bacterial seed liquid was inoculated on the first solid medium, and cultivated in a constant temperature incubator at 32° C. for 24 hours; and the colonies that grew robustly were selected.

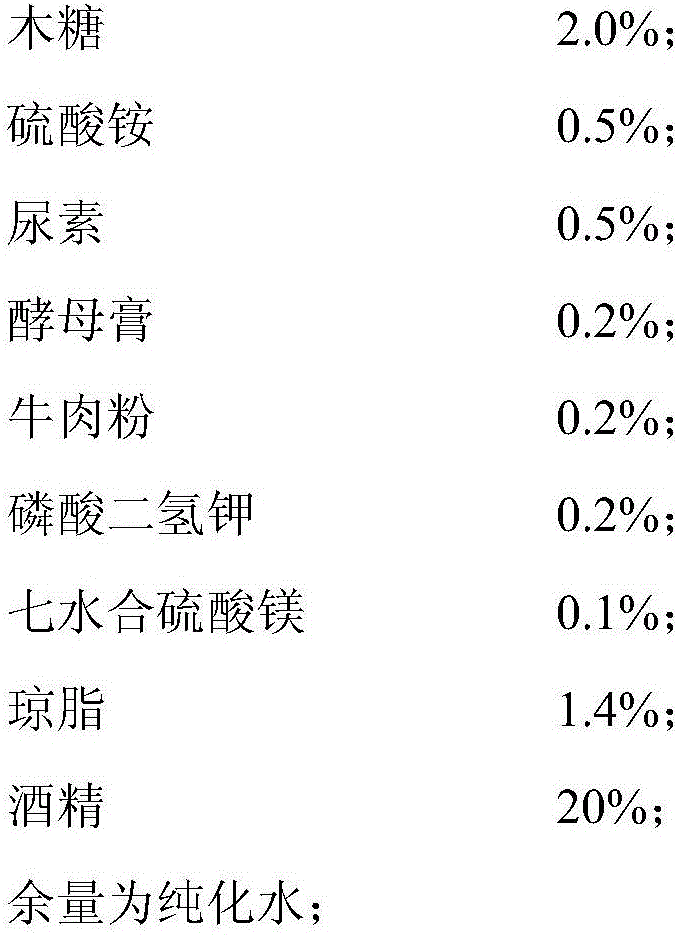

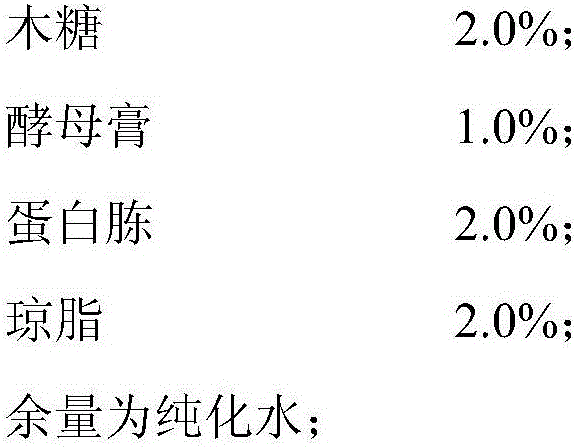

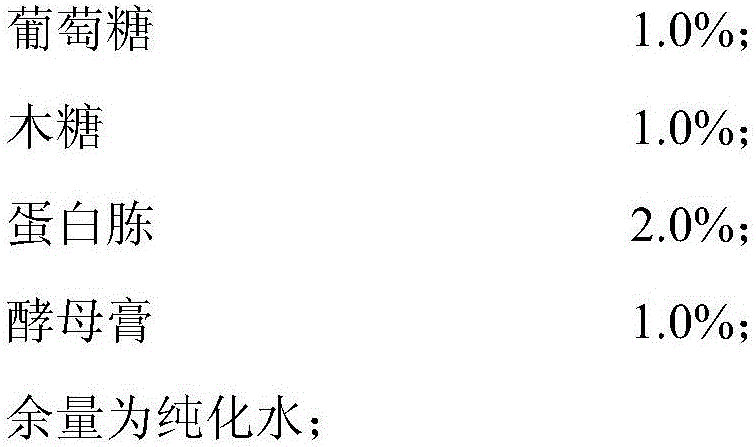

[0069] (3) The medium composition of the second to seventh solid medium is: 2.0~7.0m% xylose, 0.5m% ammonium sulfate, 25.0m% alcohol, 0.5m% urea, 0.2m% yeast extract,...

Embodiment 2

[0075] Embodiment 2: A kind of method for preparing ethanol by high-concentration fermentation of cassava and secondary starch slurry.

[0076] (1) The yeast strain is Saccharomyces cerevisiae, purchased from Angel Yeast Co., Ltd.

[0077] Under aseptic operation, place the yeast strain in 35°C 4.0Bx dilute mash for rehydration for 20 minutes, then lower the temperature to 30°C for 2 hours.

[0078] (2) Using sterile water, dilute the liquid seed liquid after rehydration and activation in step (1) by 10 times, and dilute it 8 times to obtain a seed liquid with a dilution ratio of 1:108; inoculate the seed liquid into solid On the culture medium, culture in a constant temperature incubator at 29°C for 24 hours; pick out the colonies that grow robustly.

[0079] (3) The medium composition of the second to seventh solid medium is: 2.0~7.0m% xylose, 0.5m% ammonium sulfate, 25.0m% alcohol, 0.5m% urea, 0.2m% yeast extract, 0.2m% beef powder , 0.2m% potassium dihydrogen phosphate, ...

Embodiment 3

[0084] Embodiment 3: A kind of method of preparing ethanol by high-concentration fermentation of cassava and secondary starch slurry.

[0085] A method for preparing alcohol by high-concentration fermentation of substarch slurry and cassava, including the preparation and fermentation of yeast strains;

[0086] The preparation of described yeast strain comprises the following steps:

[0087] Step 1: Rehydrate the yeast strain in the mash at 35-40°C for 15-20 minutes under aseptic conditions, then reduce the temperature of the mash to 25-34°C and cultivate for 1-2 hours to obtain the activated liquid spawn liquid; wherein, the sugar brix of the mash is 4-5 。 Bx;

[0088] Step 2: Dilute the liquid seed solution with sterile water to obtain a dilution ratio of 1:10 8 The diluted strain liquid, then inoculate the diluted strain liquid onto the first solid medium, and collect the colony after cultivating in a constant temperature incubator at 28-32°C for 20-28 hours;

[0089] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com