Antirust coating composition and use thereof

A technology of anti-rust paint and composition, applied in the direction of anti-corrosion paint, coating, metal material coating process, etc., can solve the problem of no zinc oxidation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0119] [Preparation Example 1] Preparation of Condensate of Alkyl Silicate

[0120] 38 g of ethyl silicate 40 (manufactured by COLCOAT Co., Ltd.), 18 g of industrial ethanol, 4 g of deionized water, and 0.38 g of 35% hydrochloric acid were added to the container, and after stirring at 50° C. for 3 hours, 40 g of isopropanol was added to prepare A solution of a condensate of an alkyl silicate.

preparation example 2

[0121] [Preparation Example 2] Preparation of Pigment Paste Components

[0122] The raw materials shown as the pigment paste components in Examples and Comparative Examples described in Tables 1 to 3 except for zinc powder (spherical zinc powder, flaky zinc powder, and flaky zinc alloy powder) were added to the polymer, respectively. Add glass beads to a vinyl container, vibrate for 3 hours with a paint shaker, then add zinc powder and vibrate for 5 minutes to disperse the pigment. Glass beads were removed using an 80-mesh filter to prepare pigment paste components, which were used in Examples 1 to 16 and Comparative Examples 1 to 3 described later.

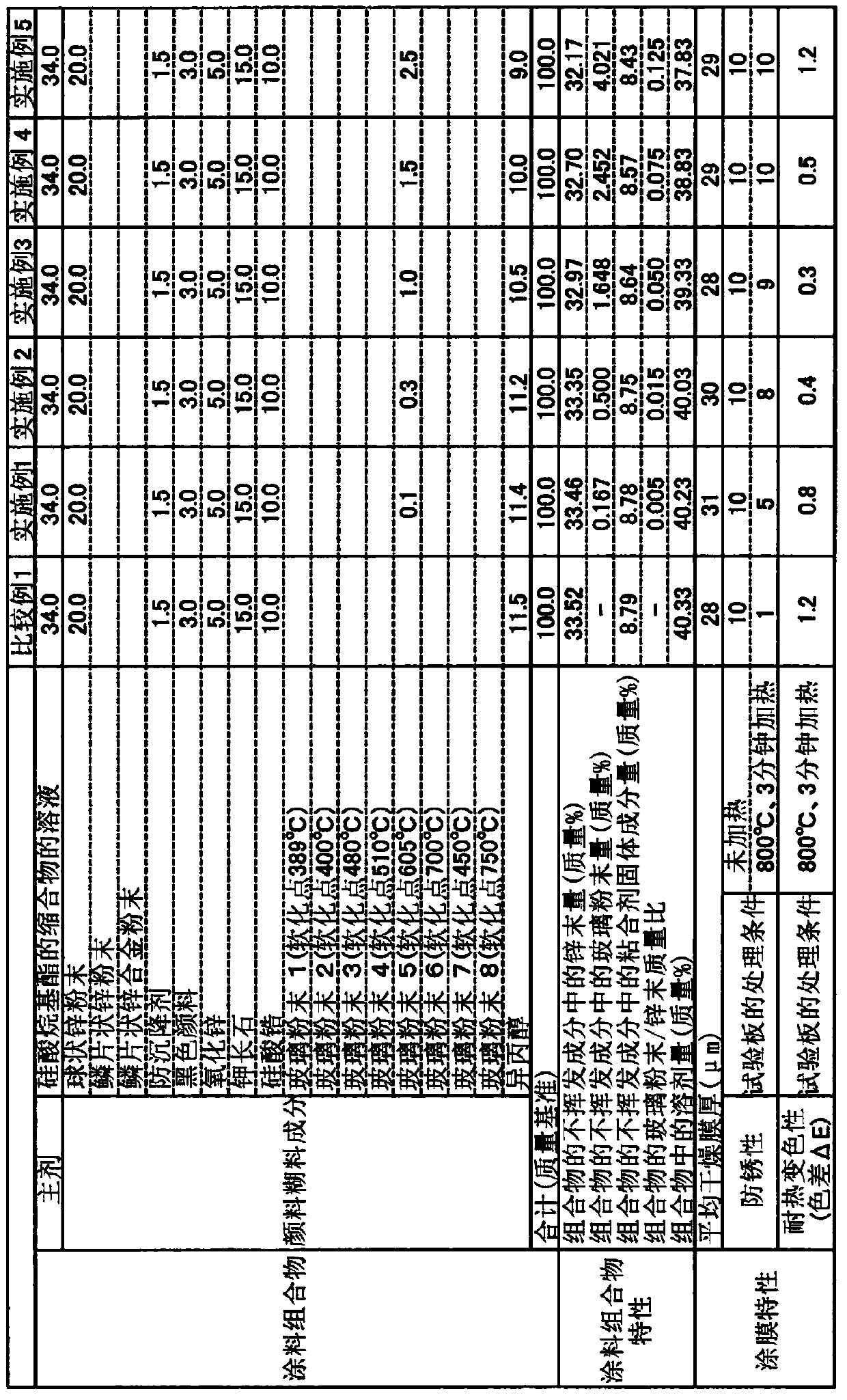

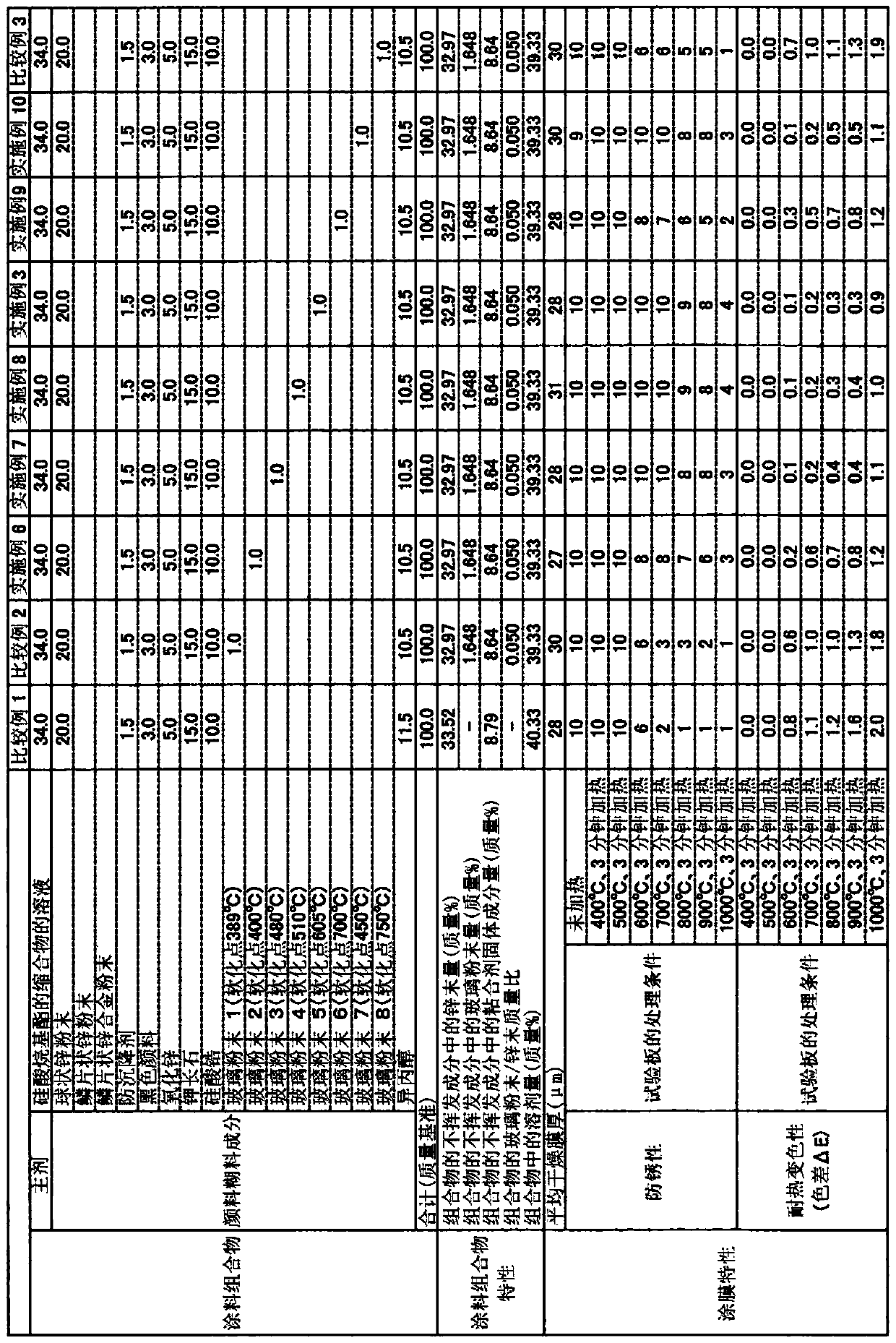

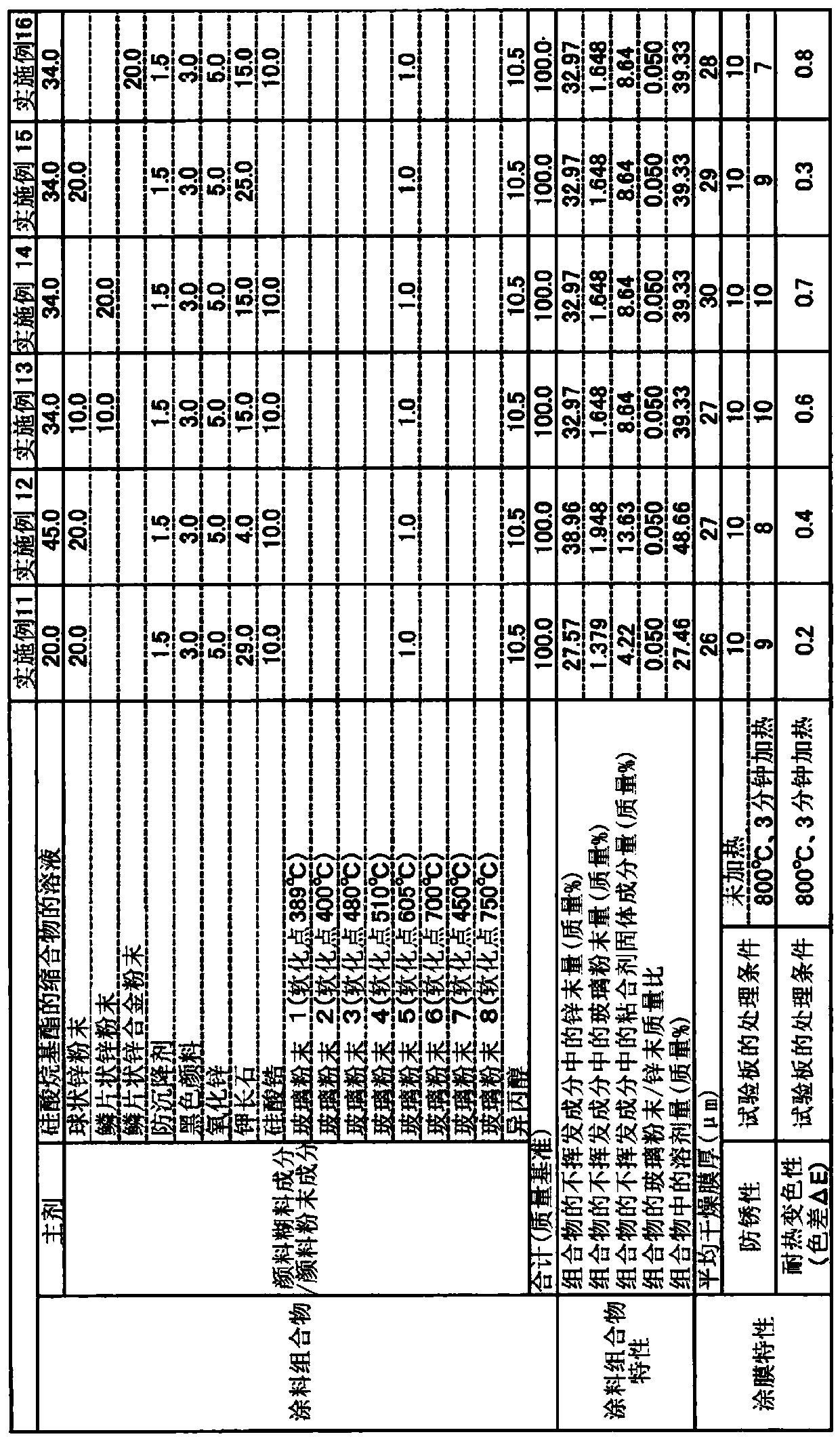

Embodiment 1~16、 comparative example 1~3

[0124] The ratio of the condensate of the alkyl silicate in Preparation Example 1 as the main component and the pigment paste component in Preparation Example 2 as the pigment paste component is the ratio described in Tables 1 to 3 (mass basis) The conditions were put into a container made of polyethylene and dispersed for 10 minutes with a high-speed disperser to prepare a rust-proof coating composition.

[0125] The outlines of the components shown in Tables 1 to 3 are as follows.

[0126] Alkyl silicate condensate solution: Alkyl silicate condensate solution prepared in Production Example 1 (solid content concentration: 15.2% by mass)

[0127] Spherical zinc powder: F-2000 (manufactured by Honjo Chemical Co., Ltd.)

[0128] Flake zinc powder: STANDART Zinc flake GTT (manufactured by Aika Corporation)

[0129] Scale-shaped zinc alloy powder: STAPA 4ZNAL7 (alloy of zinc and aluminum, manufactured by Eckard)

[0130] Anti-settling agent: AEROSIL 200 (manufactured by Japan A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com