Probiotic microcapsule taking protein aggregate-polysaccharide as wall material and preparation method thereof

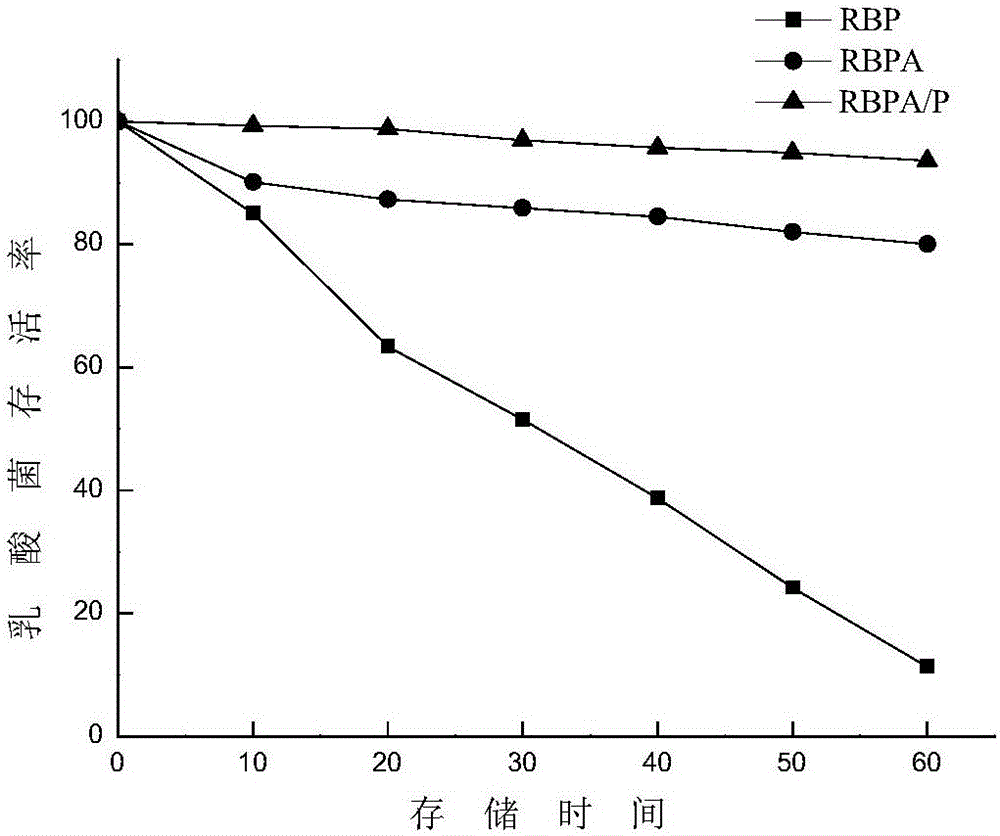

A technology of protein aggregates and probiotics, which is used in food forming, food ingredients as encapsulants, food science, etc., can solve problems such as affecting application and instability of natural proteins, and achieve good acid resistance, enteric solubility, and survival. The effect of high rate and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

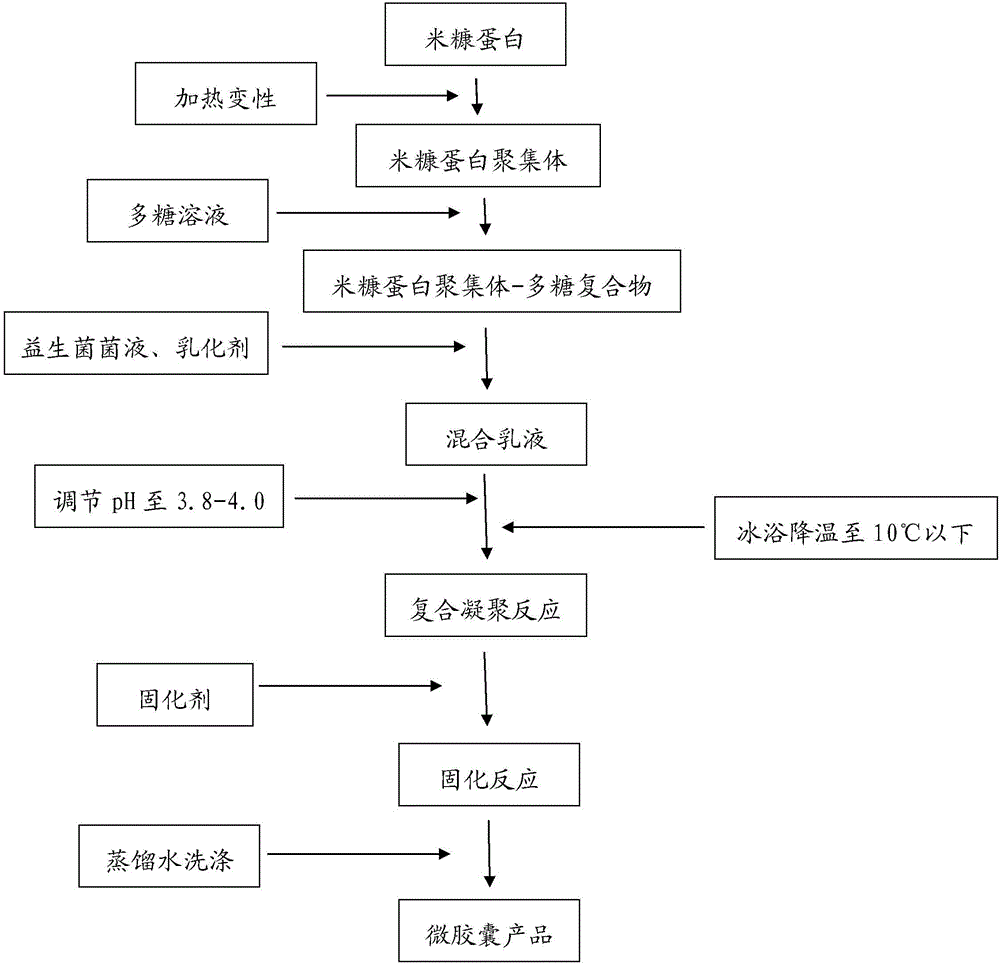

Method used

Image

Examples

Embodiment 1

[0023] Configuration of microcapsule wall material solution: rice bran protein solution with a concentration of 15%;

[0024] Activation of strains and their cultivation: the lyophilized powder of lactic acid bacteria preserved in the laboratory was added to an aqueous solution of 11% skim milk, and subjected to anaerobic constant temperature cultivation at 37° C. for 24 hours, and the skim milk solidified. Dilute 0.1mL curd with sterile water to prepare a suspension containing lactic acid bacteria. Separation of the bacterial suspension by streaking on a plate, anaerobic culture at 37°C for 24 hours, and continuous passage for 2-3 times in this way to fully activate it. Inoculate the activated lactic acid bacteria liquid into MRSC liquid medium, and after anaerobic constant temperature cultivation at 37°C to the logarithmic phase, centrifuge the obtained bacterial liquid at 4°C and 8000rmp for 10min, discard the supernatant, and collect the bacteria body;

[0025] Preparati...

Embodiment 2

[0029] Microcapsule preparation method is the same as example 1, change microcapsule wall material solution: rice bran protein aggregate solution

[0030] Preparation of rice bran protein aggregate solution: Dissolve a certain amount of rice bran protein in distilled water at a concentration of 15% (w / v) and stir for 2 hours to ensure that the rice bran protein can be completely hydrolyzed, adjust the pH of the rice bran protein solution to 2, and centrifuge Finally, the supernatant was collected, and then heated and denatured in a water bath at 90°C for 2 hours, and then cooled rapidly in an ice bath to prevent the growth of aggregates, forming a rice bran protein aggregate solution.

[0031] The embedding rate of the obtained lactic acid bacteria microcapsules reaches 75% + 1.1%. 12 CFU / g.

Embodiment 3

[0033] Microcapsule preparation method is the same as example 1, change microcapsule wall material solution: the solution+polysaccharide solution of rice bran protein aggregate (gum arabic, dextran, chitosan)

[0034]Preparation of rice bran protein aggregate solution: Dissolve a certain amount of rice bran protein in distilled water at a concentration of 15% (w / v) and stir for 2 hours to ensure that the rice bran protein can be completely hydrolyzed, adjust the pH of the rice bran protein solution to 2, and centrifuge Finally, collect the supernatant, then heat and denature it in a water bath at 90°C for 2 hours, take it out and put it in an ice bath to cool it rapidly to prevent the growth of aggregates, and the formed rice bran protein aggregate solution is ready for use;

[0035] The configuration of the microcapsule wall material solution: add 2% polysaccharide solution dropwise to the prepared rice bran protein aggregate solution according to the ratio (polysaccharide sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com