Bionic ligament and bionic ligament system

A ligament and bionic technology, applied in the field of biomedicine, can solve problems such as uncontrollable mechanical stability, foreign body rejection, and few joint points, and achieve good fixation and repair effects, good mechanical properties, and reduce mechanical loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096]

[0097] Use hexafluoroisopropanol to dissolve polylactic acid, configure an electrospinning solution with a mass concentration of 10%, add the electrospinning solution into the syringe, and connect the front tube of the micropump and the spinneret needle, set the spinning voltage to 25kV, and the solution The propulsion speed is 10mL / h, and the receiving distance is 30cm. After electrospinning, the obtained electrospun membrane was placed in a forced air drying oven at 50°C for 5 hours, then soaked in 75% alcohol for 1 hour, and then dried in a drying oven at 50°C overnight to obtain a polylactic acid nanofiber membrane.

[0098]

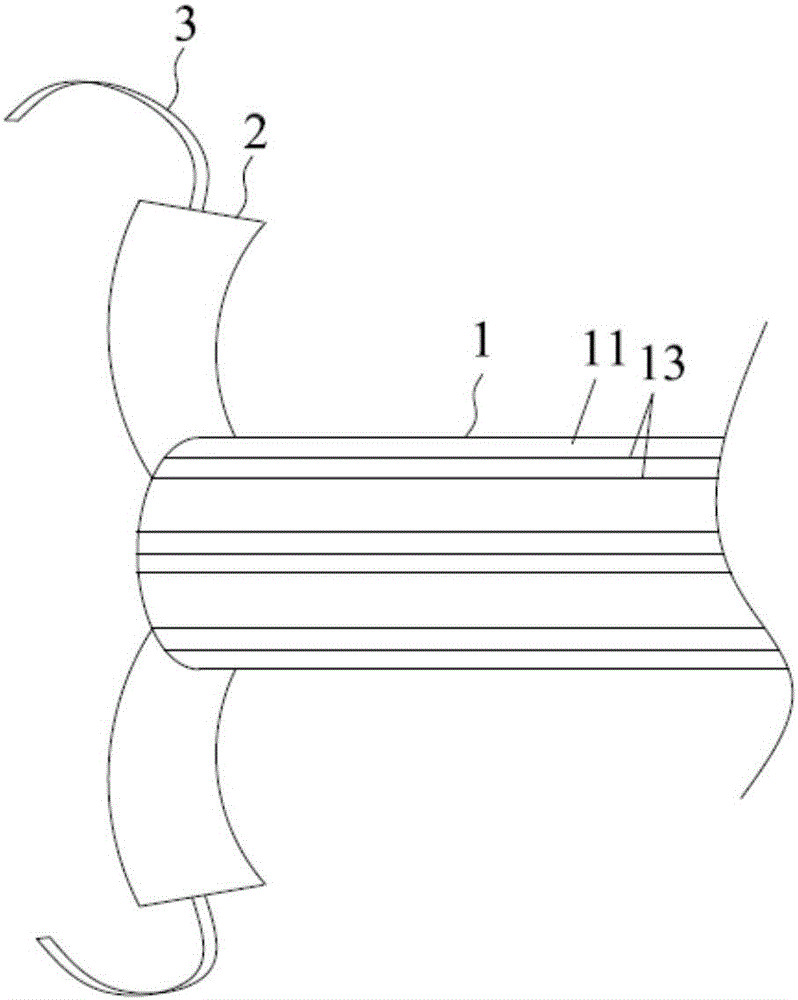

[0099] A fiber thread made of 45 (1 cluster) PET fiber filaments was selected, and the fiber thread was fixed on the polylactic acid nanofiber film by sewing to obtain a composite film. Wherein, one fiber thread is made of one cluster of PET fiber threads, four fiber threads are one fiber thread group, the fiber threads in the same fiber...

Embodiment 2

[0105]

[0106] Use hexafluoroisopropanol to dissolve polycaprolactone, prepare a mass concentration of 10% electrospinning solution, add the electrospinning solution into the syringe, and connect the front tube of the micropump and the spinning needle, and set the spinning voltage to 28.5kV , solution advancing speed 8mL / h, receiving distance 30cm. After electrospinning, the obtained electrospun membrane was placed in an air-blast drying oven at 50°C for 5 hours, then soaked in 75% alcohol for 1 hour, and then dried in a drying oven at 50°C overnight to obtain a polycaprolactone nanofiber membrane.

[0107]

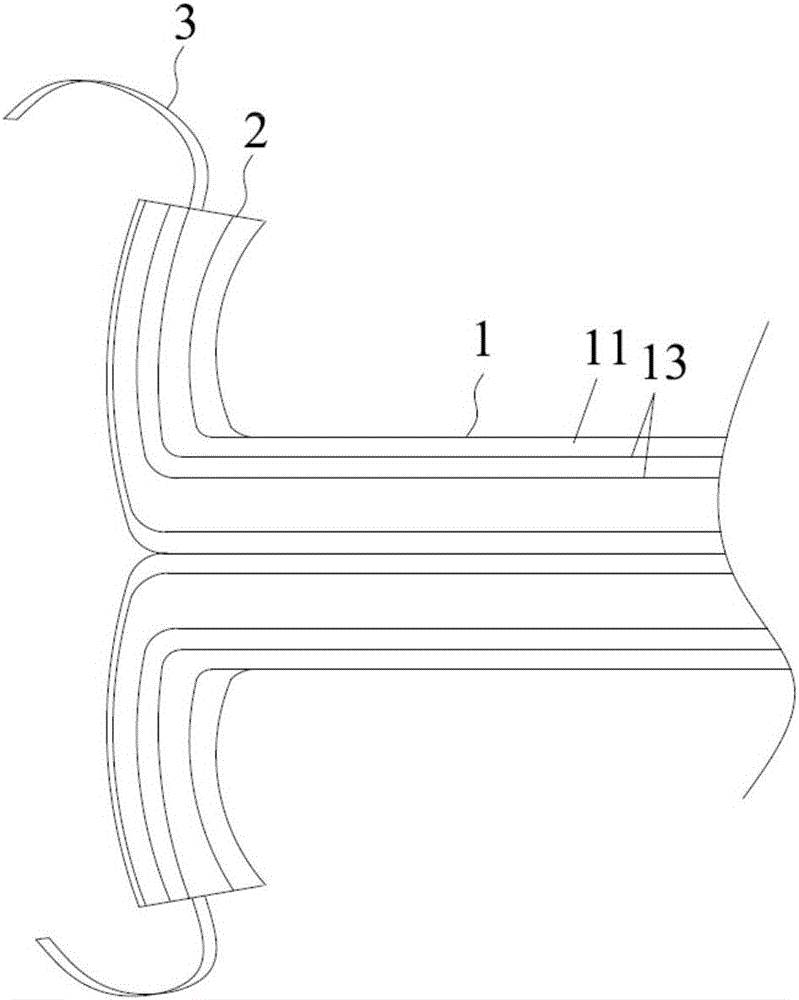

[0108] A fiber thread made of 25 (1 cluster) PET fiber filaments was selected, and the fiber thread was fixed on the polycaprolactone nanofiber film by sewing to obtain a composite film. Among them, one fiber thread is made of a cluster of PET fibers, two fiber threads are a fiber thread group, the fiber threads in the same fiber thread group extend in the same direc...

Embodiment 3

[0114]

[0115] Use hexafluoroisopropanol to dissolve L-polylactic acid, prepare an electrospinning solution with a mass concentration of 20%, add the electrospinning solution into the syringe, connect the front tube of the micropump and the spinning needle, and set the spinning voltage to 35kV , solution advancing speed 2.5mL / h, receiving distance 30cm. After electrospinning, the obtained electrospun membrane was placed in a forced air drying oven at 50°C to dry for 5 hours, then soaked in 75% alcohol for 1 hour, and then placed in a drying oven to dry at 50°C overnight to obtain a L-polylactic acid nanofiber membrane.

[0116]

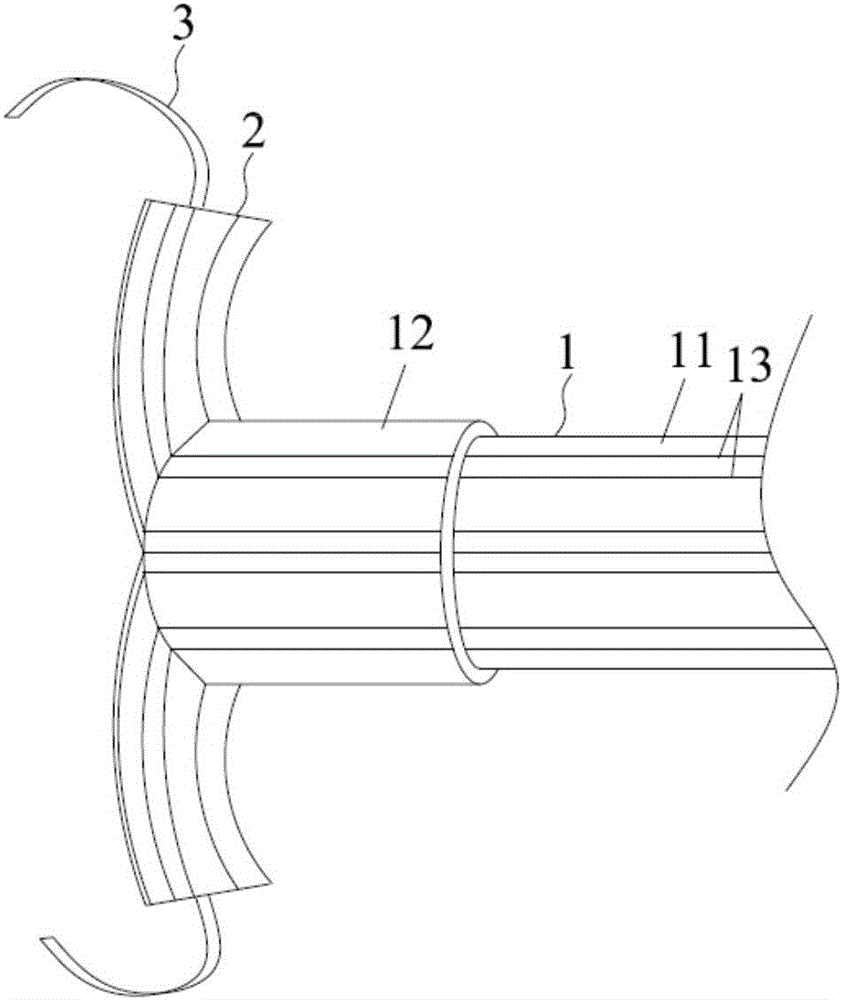

[0117] Use hexafluoroisopropanol to dissolve L-polylactic acid, configure the L-polylactic acid solution with a mass concentration of 8%, then add hydroxyapatite powder to the L-polylactic acid solution, and the mass of polylactic acid and hydroxyapatite The ratio is 5:2, stirred at a rotation speed of 1500 rpm for 30 minutes, introduced into a w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com