Solid sirolimus self-microemulsion preparation and preparation method thereof

A technology of sirolimus and emulsion preparation, applied in the field of medicine, can solve the problems of difficult transportation, storage and taking, affecting the disintegration and self-emulsifying effect, hardening of the capsule, etc., so as to improve the solubility and dissolution, improve the Dissolution and in vivo bioavailability, the effect of large dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 【prescription】

[0025]

[0026] 【Preparation Process】

[0027] Preparation of liquid sirolimus self-microemulsion preparation: accurately weigh 10 mg of sirolimus and add it to 100 mg of co-emulsifier diethylene glycol monoethyl ether, stirring continuously until sirolimus is dissolved; Add 150 mg of oil phase polyethylene glycol glyceride oleate and 200 mg of emulsifier polyoxyethylene-35-castor oil successively, and continue to stir until a light yellow clear solution is formed to obtain a liquid sirolimus self-microemulsion preparation;

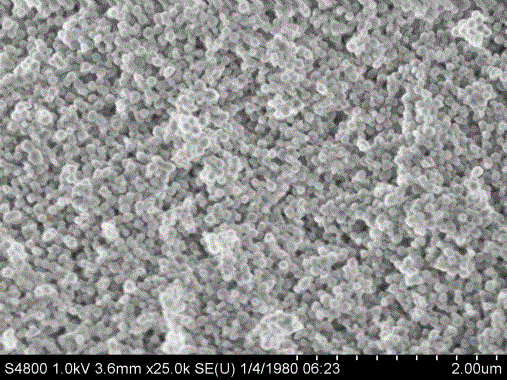

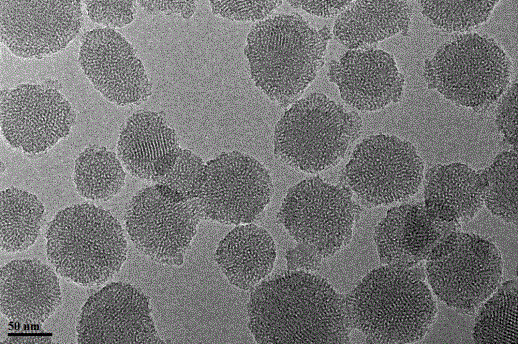

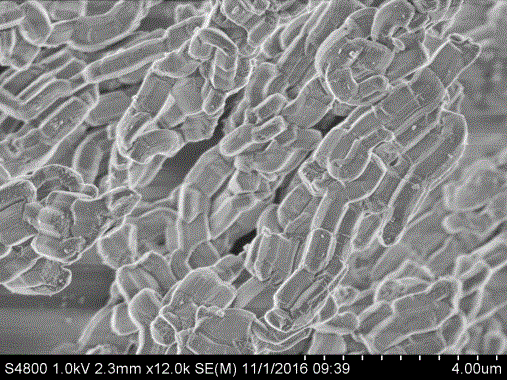

[0028] Preparation of mesoporous silica nanoparticles: Dissolve 1500 mg of cetyltrimethylammonium bromide in 1000 mL of deionized water, and add 30 mL of 0.5M sodium hydroxide solution dropwise to it. Stop stirring (speed is 500 r·min -1 ) For 30 min. Subsequently, a mixed solution of 5 mL of tetraethyl silicate and 8 mL of absolute ethanol was added. After the reaction was maintained for 2 h, the reaction was cooled to room temperature...

Embodiment 2

[0031] 【prescription】

[0032]

[0033] 【Preparation Process】

[0034] Preparation of liquid sirolimus self-microemulsion preparation: accurately weigh 50 mg of sirolimus and add it to 500 mg of co-emulsifier diethylene glycol monoethyl ether, stirring continuously until sirolimus is dissolved; Add 750 mg of oil-phase oleic acid polyethylene glycol glyceride and 1000 mg of emulsifier polyoxyethylene-35-castor oil successively, and keep stirring until a light yellow clear solution is formed to obtain a liquid sirolimus self-microemulsion preparation;

[0035] Preparation of mesoporous silica nanoparticles: Dissolve 1500 mg of cetyltrimethylammonium bromide in 1000 mL of deionized water, and add 30 mL of 0.5M sodium hydroxide solution dropwise to it. Stop stirring (speed is 500 r·min -1 ) For 30 min. Subsequently, a mixed solution of 5 mL of tetraethyl silicate and 8 mL of absolute ethanol was added. After the reaction was maintained for 2 h, the reaction was cooled to room temperatu...

Embodiment 3

[0038] 【prescription】

[0039]

[0040] 【Preparation Process】

[0041] Preparation of liquid sirolimus self-microemulsion preparation: accurately weigh 100 mg of sirolimus and add it to 1000 mg of co-emulsifier diethylene glycol monoethyl ether, stirring continuously until sirolimus is dissolved; Add 1500 mg of oil phase polyethylene glycol glyceride oleate and 2000 mg of emulsifier polyoxyethylene-35-castor oil successively, and continue to stir until a light yellow clear solution is formed to obtain a liquid sirolimus self-microemulsion preparation;

[0042] Preparation of mesoporous silica nanoparticles: Dissolve 1500 mg of cetyltrimethylammonium bromide in 1000 mL of deionized water, and add 30 mL of 0.5M sodium hydroxide solution dropwise to it. Stop stirring (speed is 500 r·min -1 ) For 30 min. Subsequently, a mixed solution of 5 mL of tetraethyl silicate and 8 mL of absolute ethanol was added. After the reaction was maintained for 2 h, the reaction was cooled to room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com