Octreotide acetate dry powder inhalation preparation and preparation method thereof

A technology for inhalation of octreotide acetate and dry powder, which is applied in powder delivery, pharmaceutical formulations, peptide/protein components, etc. It can solve the problems of easy adhesion, aggregation, dispersion, etc., and achieve high-efficiency preparation, high emptying rate and deposition rate, and fluidity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

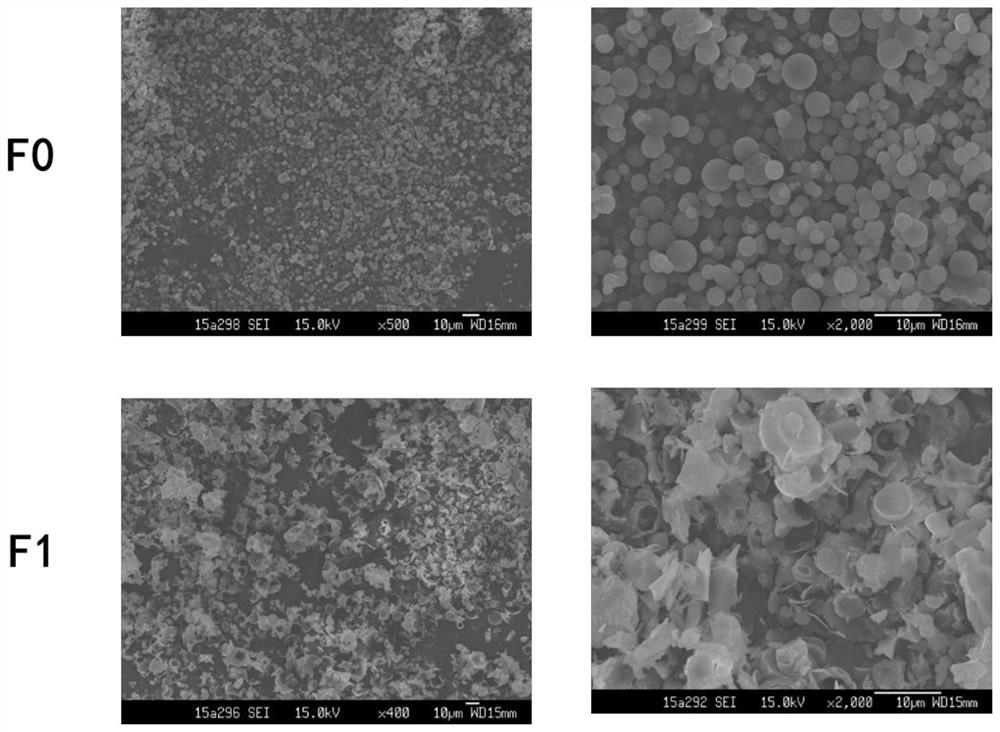

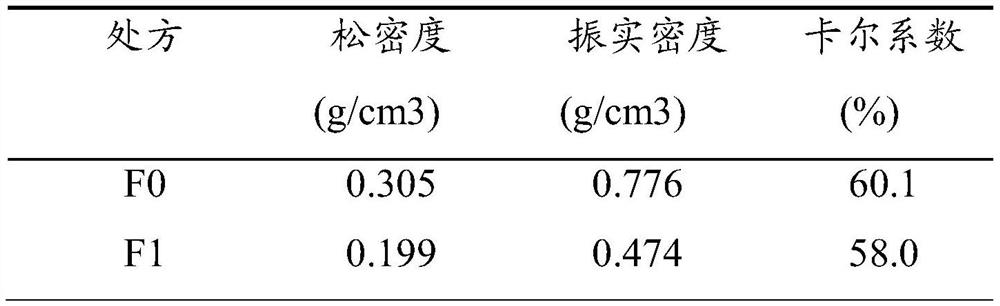

[0038] Example 1 Preparation and in vitro evaluation of octreotide acetate dry powder inhalation preparation

[0039] Mannitol is used as a drug carrier, ammonium carbonate is used as a porogen, the mass ratio of mannitol to ammonium carbonate is 8:2, the solid content is 1%, the drug content is 1%, and the spray drying solvent is water. Its preparation method comprises the following steps:

[0040]Weigh 0.8g of mannitol and 0.2g of ammonium carbonate, and dissolve them in 98ml of distilled water; weigh 1.0g of octreotide acetate, dissolve them in the above solution, and prepare a spray drying solution. During the spray drying process, water is used as the spray drying solvent, the inlet temperature (inlet air temperature) is 100°C, and the compressed air flow rate is 0.8m 3 / min, the atomization pressure is 150kPa, and the liquid supply rate is 1.5mL / min to obtain octreotide acetate fractal powder. The drug powder is packed into capsules and packed into a dry powder inhalat...

Embodiment 2

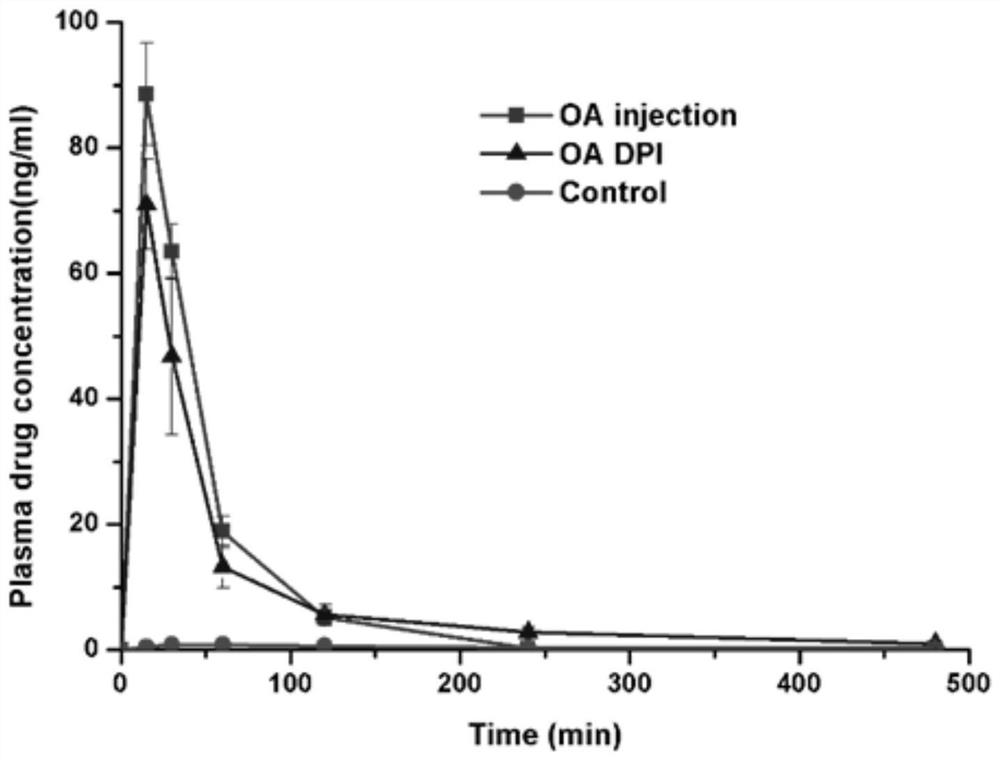

[0053] Example 2 Pharmacokinetic evaluation of octreotide acetate dry powder inhalation preparation

[0054] Mannitol is used as a drug carrier, ammonium carbonate is used as a porogen, the mass ratio of mannitol to ammonium carbonate is 1:1, the solid content is 3%, the drug content is 1%, and the spray drying solvent is water. Its preparation method comprises the following steps:

[0055] Weigh 1.5g of mannitol and 1.5g of ammonium carbonate, and dissolve them in 96ml of distilled water; weigh 1.0g of octreotide acetate, dissolve them in the above solution, and prepare a spray drying solution. During the spray drying process, water is used as the spray drying solvent, the inlet temperature is 110°C, and the air flow is 0.7m 3 / min, the atomization pressure is 165kPa, and the liquid supply rate is 1.8mL / min to obtain octreotide acetate fractal powder. The medicine powder is packed into a capsule and packed into a dry powder inhalation device to obtain the octreotide acetate...

Embodiment 3

[0063] With mannitol as the drug carrier and ammonium carbonate as the porogen, the mass ratio of mannitol:ammonium carbonate is 10:0, 9:1, 8:2, 7:3, 6:4, 5:5. Take 2.0g of mannitol and ammonium carbonate, dissolve in 97ml of distilled water; weigh 1.0g of octreotide acetate, and prepare a spray-dried solution according to the ratio of solid content 2% and drug content 1%. During the spray drying process, water is used as the spray drying solvent, the inlet temperature (inlet air temperature) is 120°C, and the compressed air flow rate is 0.6m 3 / min, the atomization pressure is 155kPa, and the liquid supply rate is 2.0mL / min to obtain octreotide acetate fractal powder. The drug powder is put into capsules and put into a dry powder inhalation device to obtain dry powder prescriptions of different ratios of mannitol and porogen ammonium carbonate.

[0064] The two parameters of powder yield and aerodynamic diameter were selected as the investigation index, and the results of ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com