Chemoembolization microspheres with microwave hyperthermia sensitization function, and preparation method and application thereof

A technique of chemoembolization and microwave sensitization, applied in the field of biomedicine, can solve the problems of residual tumor margin area and treatment failure, and achieves the effects of good biocompatibility, simple preparation method and good clinical application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

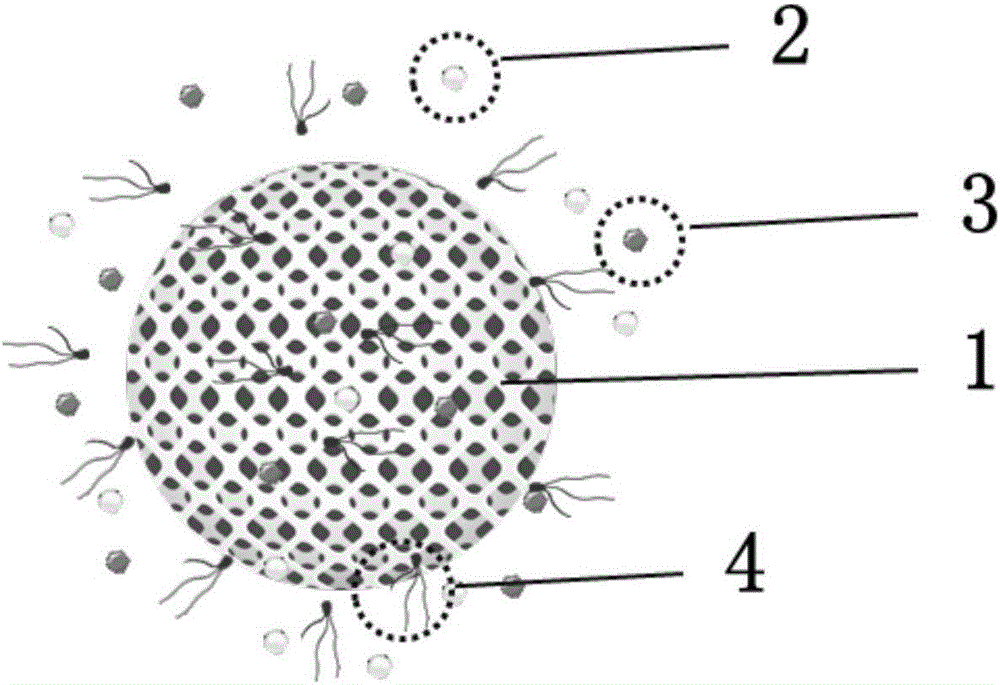

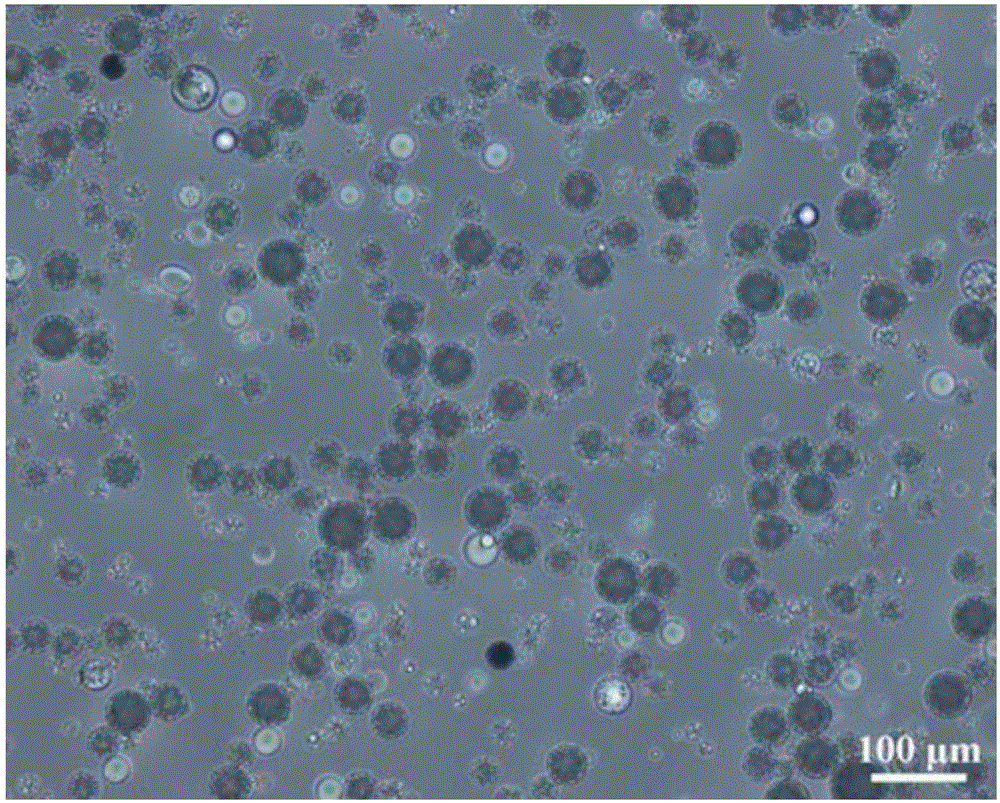

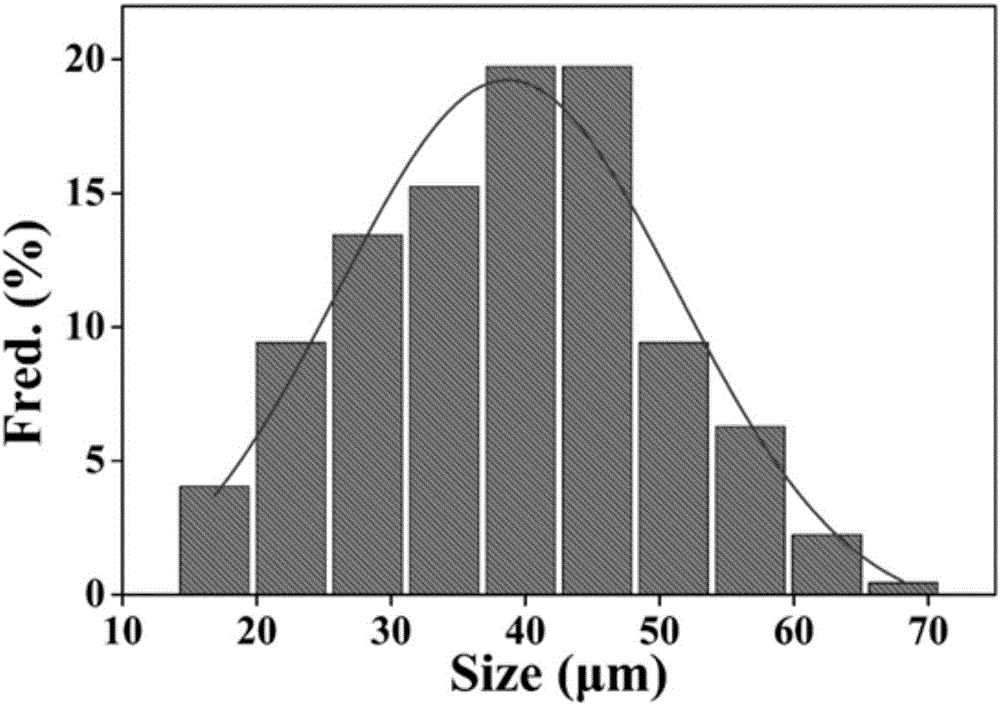

[0042] Example 1 Preparation of Porous Microspheres for Chemoembolization with Microwave Sensitization Function

[0043] Dissolve 10 mg of ammonium bicarbonate in 0.5 mL of deionized water to form an internal water phase; then dissolve 200 mg of polylactic-glycolic acid (molecular weight: 80,000, lactic acid: glycolic acid = 50:50) in 4 mL of dichloromethane to form an oil phase; The inner water phase was added to the oil phase, ultrasonically emulsified to obtain emulsion A; 500 mg of polyethylene glycol was dissolved in 50 ml of deionized water to obtain the outer water phase B; the obtained emulsion A was added to the outer water phase B, 1200r / Min mechanically stirred for 4h to obtain the porous microcapsules; sodium chloride (20mg / mL) and doxorubicin (1mg / mL) were dissolved in deionized water to form a solution C; the porous microspheres were soaked in solution C for 1h, The chemoembolization porous microspheres with a particle size of 20-70 μm and microwave sensitizatio...

Embodiment 2

[0044] Example 2 Preparation of Porous Microspheres for Chemoembolization with Microwave Sensitization Function

[0045] Dissolve 10 mg of ammonium bicarbonate in 0.5 mL of deionized water to form an internal water phase; then dissolve 200 mg of polylactic-glycolic acid (molecular weight: 50,000, lactic acid: glycolic acid = 10:90) in 4 mL of dichloromethane to form an oil phase; The inner water phase was added to the oil phase, ultrasonically emulsified to obtain emulsion A; 500mg polyethylene glycol was dissolved in 50ml deionized water to obtain the outer water phase B; the obtained emulsion A was added to the outer water phase B, 1400r / Min mechanically stirred for 3h to obtain the porous microcapsules; sodium chloride (10mg / mL) and doxorubicin (1mg / mL) were dissolved in deionized water to form solution C; the porous microspheres were soaked in solution C for 1h, The chemoembolization porous microspheres with a particle size of 20-70 μm and microwave sensitization function...

Embodiment 3

[0046] Example 3 Preparation of Porous Microspheres for Chemoembolization with Microwave Sensitization Function

[0047] Dissolve 10 mg of ammonium bicarbonate in 0.5 mL of deionized water to form an internal water phase; then dissolve 200 mg of polylactic-glycolic acid (molecular weight: 150,000, lactic acid: glycolic acid = 75:25) in 4 mL of dichloromethane to form an oil phase; The inner water phase was added to the oil phase, ultrasonically emulsified to obtain emulsion A; 1000mg polyethylene glycol was dissolved in 50ml deionized water to obtain the outer water phase B; the obtained emulsion A was added to the outer water phase B, 600r / Min mechanically stirred for 5h to obtain the porous microcapsules; sodium chloride (30mg / mL) and doxorubicin (1mg / mL) were dissolved in deionized water to form a solution C; the porous microspheres were soaked in solution C for 1h, Chemoembolization porous microspheres with a particle size of 600-700 μm and microwave sensitization functio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com