Foamed composite bio-enzyme deodorant as well as preparation method and application thereof

A compound biological enzyme and foaming technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as difficult desorption of absorbents, damage to pipes, and complicated extraction processes, so as to reduce the generation of odorous substances, Growth-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

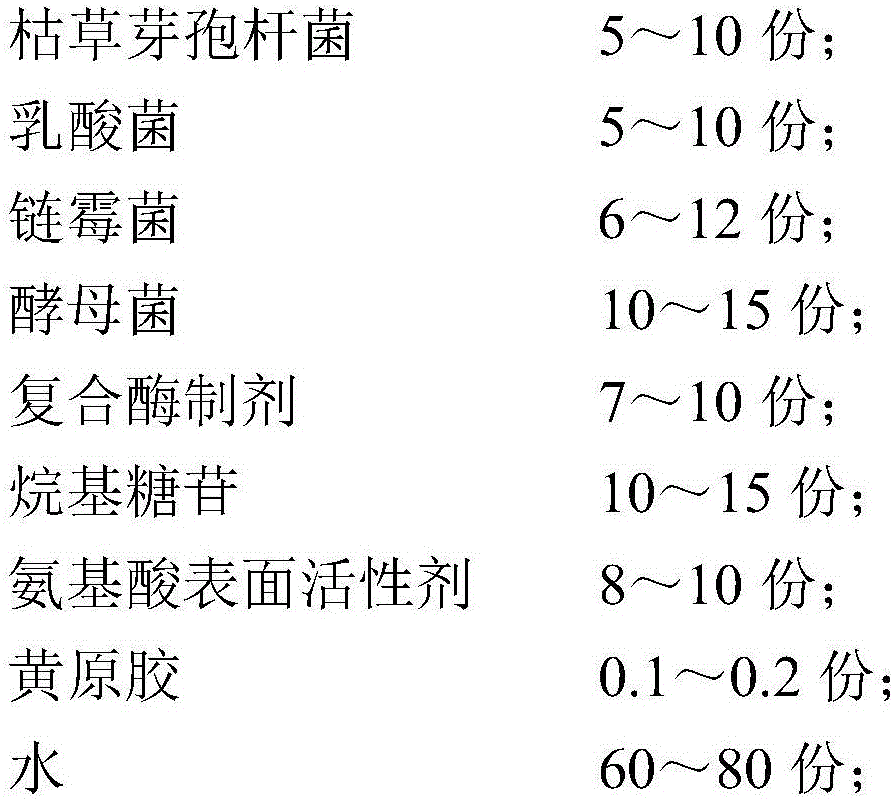

Method used

Image

Examples

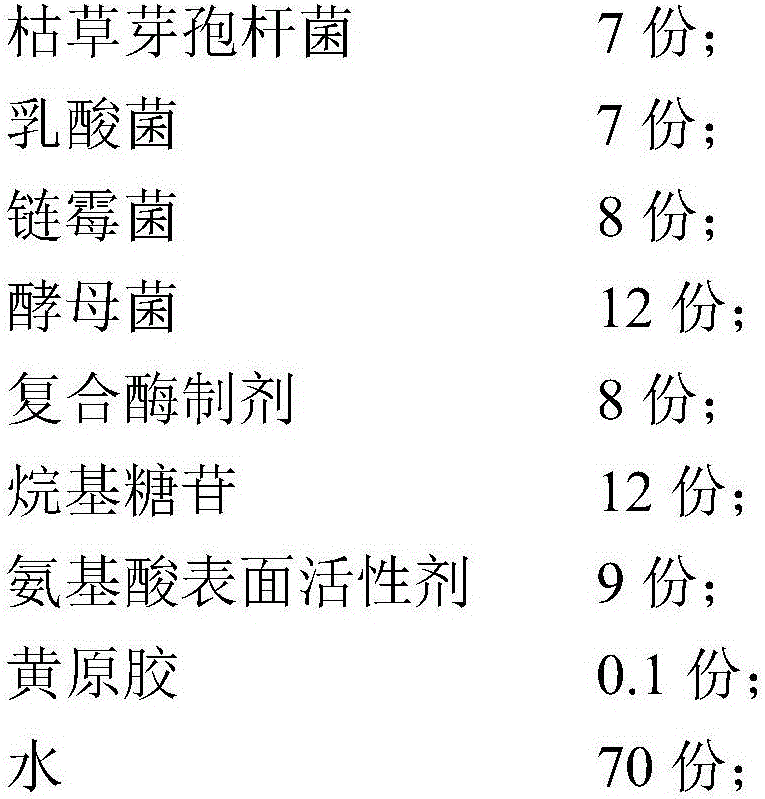

Embodiment 1

[0047] (1) Strain culture

[0048] Take the preserved Bacillus subtilis strain and inoculate it on the beef extract peptone solid medium, culture at 37°C for 2 days to activate the strain, and then transfer the activated strain to the beef extract peptone liquid medium (without agar) for 160r / min shaking and expanding culture until the number of viable Bacillus subtilis is 2×10 9 CFU / ml;

[0049] Inoculate the preserved Lactobacillus acidophilus strains on the MRS solid medium, culture at 37°C for 2 days to activate the strains, and then transfer the activated strains to the MRS liquid medium (without agar) and shake at 160r / min Expand the culture until the number of live bacteria of Lactobacillus acidophilus is 2×10 9 CFU / ml;

[0050] Inoculate the preserved Streptomyces flavinus strains on the Gaoshi No. 1 solid medium, and incubate at 28°C for 5 days to activate the strains, and then transfer the activated strains to the Gaoshi No. 1 liquid medium (without agar) Medium...

Embodiment 2

[0056] (1) Strain culture

[0057] Take the preserved Bacillus subtilis strain and inoculate it on the beef extract peptone solid medium, culture at 37°C for 2 days to activate the strain, and then transfer the activated strain to the beef extract peptone liquid medium (without agar) for 160r / min shaking and expanding culture until the number of viable Bacillus subtilis is 1×10 8 CFU / ml;

[0058] Inoculate the preserved Lactobacillus acidophilus strains on the MRS solid medium, culture at 37°C for 2 days to activate the strains, and then transfer the activated strains to the MRS liquid medium (without agar) and shake at 160r / min Expand the culture until the viable count of Lactobacillus acidophilus is 1×10 8 CFU / ml;

[0059] Inoculate the preserved Streptomyces flavinus strains on the Gaoshi No. 1 solid medium, and incubate at 28°C for 5 days to activate the strains, and then transfer the activated strains to the Gaoshi No. 1 liquid medium (without agar) Medium 160r / min s...

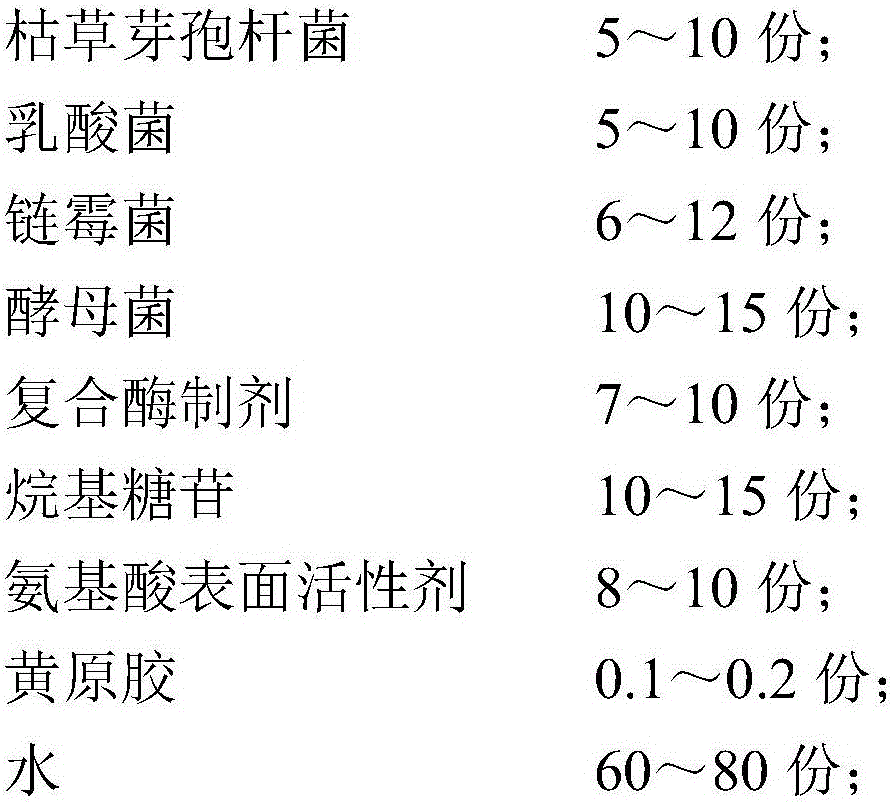

Embodiment 3

[0065] (1) Strain culture

[0066] Take the preserved Bacillus subtilis strain and inoculate it on the beef extract peptone solid medium, culture at 37°C for 2 days to activate the strain, and then transfer the activated strain to the beef extract peptone liquid medium (without agar) for 160r / min shaking and expanding culture until the number of viable Bacillus subtilis is 5×10 9 CFU / ml;

[0067] Inoculate the preserved Lactobacillus acidophilus strains on the MRS solid medium, culture at 37°C for 2 days to activate the strains, and then transfer the activated strains to the MRS liquid medium (without agar) and shake at 160r / min Expand the culture until the viable count of Lactobacillus acidophilus is 5×10 9 CFU / ml;

[0068] Inoculate the preserved Streptomyces flavinus strains on the Gaoshi No. 1 solid medium, culture at a constant temperature of 28°C for 5 days to activate the strains, and then transfer the activated strains to the Gaoshi No. 1 liquid culture medium for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Enzyme activity | aaaaa | aaaaa |

| Viable count | aaaaa | aaaaa |

| Viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com