Copper-based solid-phase catalyst and its preparation method and application

A solid-phase catalyst, catalyst technology, applied in heterogeneous catalyst chemical elements, chemical instruments and methods, physical/chemical process catalysts, etc. , consuming experimental time and other problems to achieve the effect of preventing agglomeration, improving conversion rate and selectivity, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

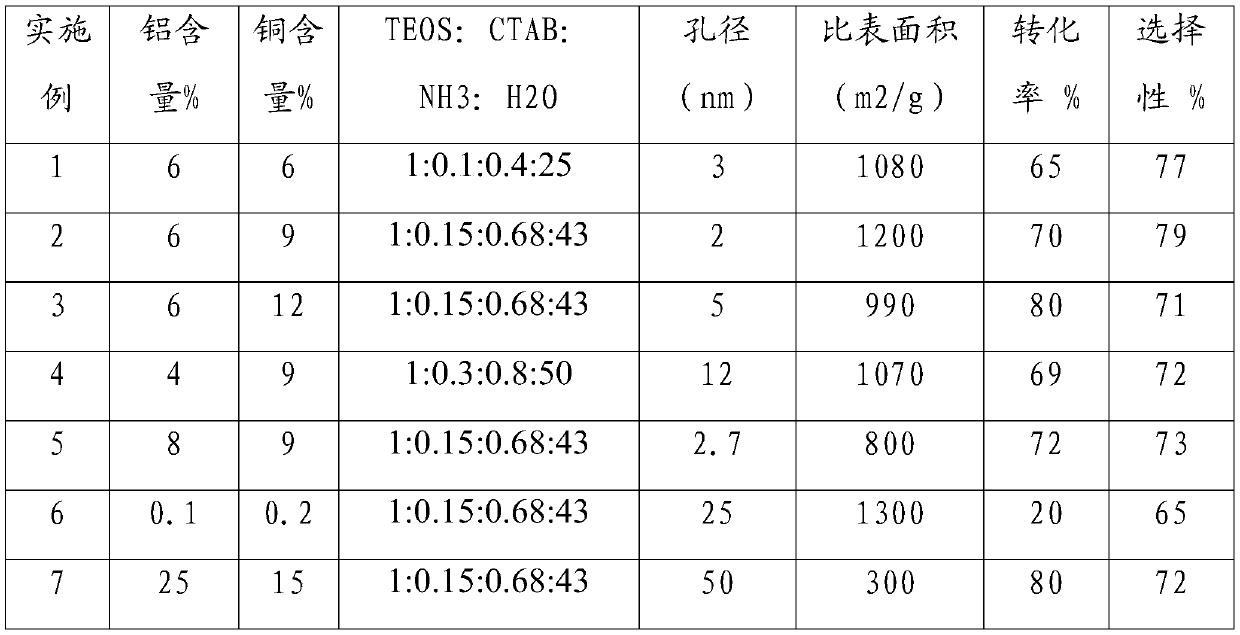

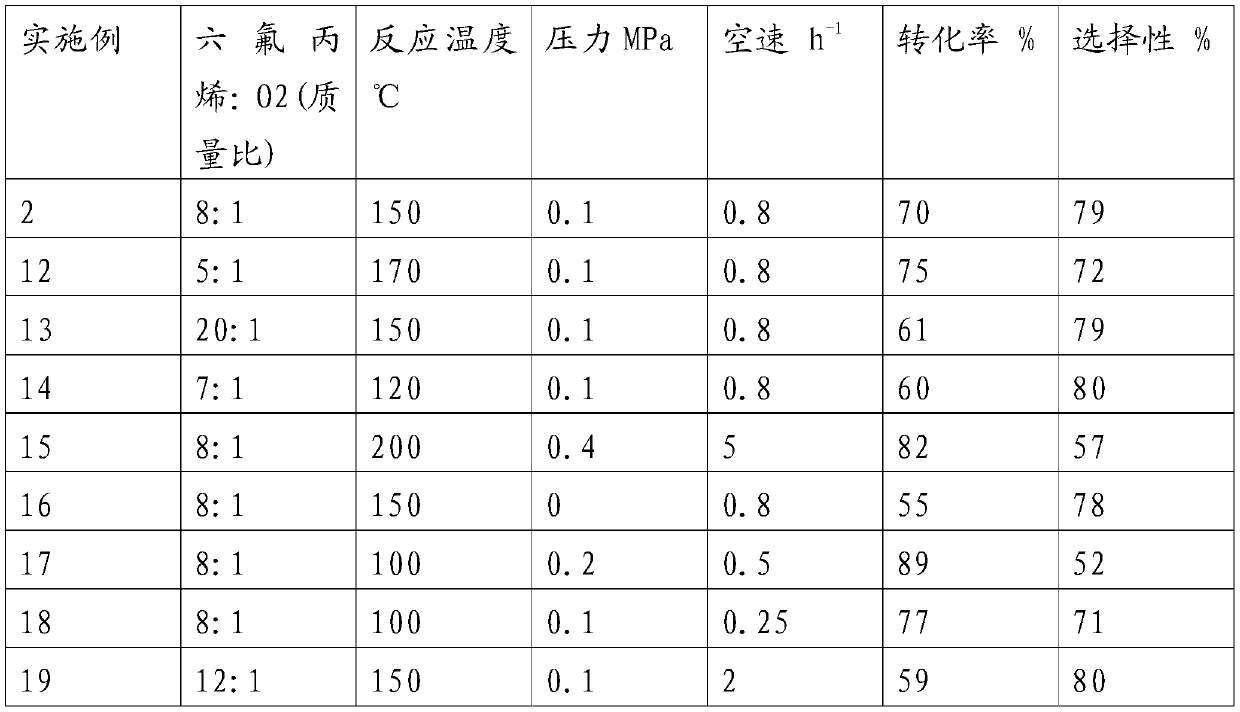

[0024] The preparation of catalyst: dissolve a certain amount of template agent hexadecyltrimethylammonium bromide in a certain amount of distilled water, stir at room temperature for 30 minutes, then add a certain amount of ammonia water, then add tetraethyl orthosilicate ( TEOS), the molar ratio of each component in the solution is: TEOS:CTAB:NH3:H2O=1:0.10-0.30:0.40-0.80:25-50. The above solution was stirred again at room temperature for 1 hour, then a certain amount of aluminum trichloride solution and cupric chloride solution were added thereto (the molar ratio was TEOS:Cu:Al=1:0.01-0.25:0.01-0.60), by adding Different amounts of aluminum trichloride and copper chloride were used to prepare different catalysts. Stir again at room temperature for 1 hour, then put it into a reaction kettle with a polytetrafluoroethylene liner, and crystallize at 120 °C for 48 hours. The sample is taken out again, then suction filtered and washed, dried, and then roasted for 6 hours at 400 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com