Composite material for carrying out photocatalytic degradation on microcystin and preparation method and application thereof

A catalytic material and composite photocatalytic technology, applied in the field of g-C3N4/BiOI composite visible light catalytic material and its preparation, to achieve the effects of rapid migration, efficient use of solar energy, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of BiOI: Weigh 0.97g Bi(NO 3 ) 3 ·5H 2O in 20mL deionized water, ultrasonicated for 30min and magnetically stirred for 10min, 0.332g KI was dissolved in 20mL deionized water, and then the KI solution was added dropwise to the Bi(NO 3 ) 3 ·5H 2 In the O solution, stirring was continued to obtain a uniformly distributed brick-red liquid. After natural sedimentation, the precipitate was collected, washed alternately with deionized water and ethanol for 3 times, and the brick-red precipitate was dried at 60°C for 12 hours to obtain BiOI.

Embodiment 2

[0034] g-C 3 N 4 Preparation of photocatalyst: Weigh 8g of melamine and place it in a semi-closed alumina crucible, move it into a muffle furnace and calcinate at 550°C for 4h with a heating rate of 2.3°C / min, cool naturally to room temperature and grind to obtain g-C 3 N 4 Powder.

Embodiment 3

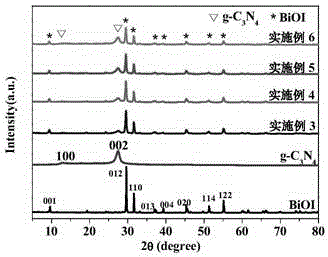

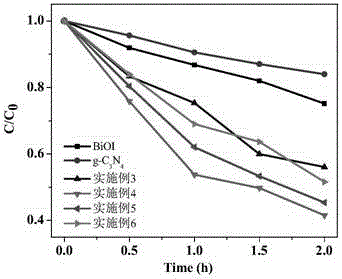

[0036] g-C 3 N 4 Preparation of / BiOI composite photocatalytic material: Weigh 2 g of melamine and 1.0 g of the BiOI powder obtained in Example 1, dissolve them together in 50 mL of absolute ethanol, and stir for 30 min, then put the stirred solution into an oven at 60°C for drying Dry for 3 hours, then move the dried powder into a semi-closed alumina crucible, place it in a muffle furnace and calcinate at 550°C for 4 hours, the heating rate is 2.3°C / min, cool to room temperature and grind to obtain g-C 3 N 4 / BiOI composite photocatalytic material, where g-C 3 N 4 The mass ratio in the composite photocatalytic material is 50wt%.

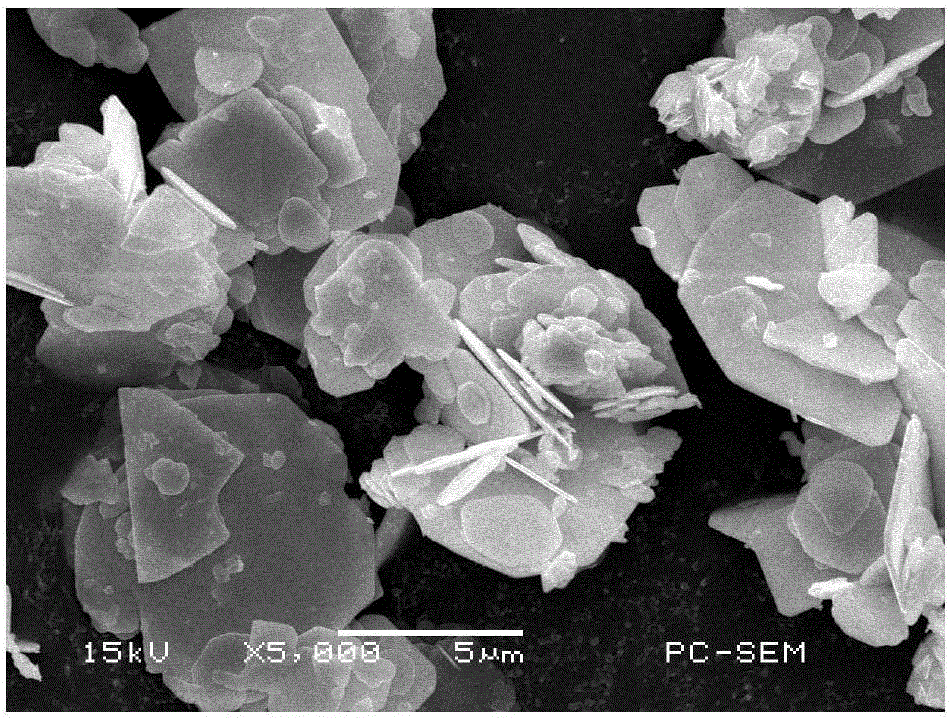

[0037] The SEM analysis result of pure BiOI ( Figure 1a ) shows that pure BiOI is a flower-like structure formed by irregular accumulation of many irregular round cakes. The thickness of nanosheets is about 30nm and the diameter is about 100-500nm. g-C 3 N 4 FESEM analysis results of / BiOI composite visible photocatalytic material ( Figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com