Multilevel porous/mesoporous organic silicon ball and preparation method thereof

A pore mesoporous and organosilicon technology, applied in the field of hierarchical porous mesoporous organosilicon spheres and their preparation, can solve the problems of difficult controllable release, restrict the application of hierarchical porous materials, etc., and achieve easy release and enhanced degradability. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Figure 12 Schematically shows the process flow diagram of the preparation method of the present invention, by Figure 12 It can be seen that the preparation method of the present invention includes, for example: sol-gel method and surfactant-directed method to synthesize SiO with controllable particle size 2 Nanoparticles; under hydrothermal conditions, silicon source and organosilicon source precursors are co-hydrolyzed and co-condensed to form a dendritic shell with adjustable thickness; after the product is separated (for example, with ethanol and water), it is washed multiple times; (for example, with hydrochloric acid extraction with ethanol at 75 degrees centigrade) to remove the surfactant and wash to obtain the product. Hereinafter, the method for preparing the hierarchically porous mesoporous silica nanoparticles will be described in detail.

[0041] First, using traditional sol-gel method, using surfactants as directing agents to synthesize monodisperse s...

Embodiment 1

[0062] Mix 45mL of deionized water and 5g of CTAC, and record it as solution A. Mix 9mL deionized water and 1gTEA, and record it as solution B. Mix 20g of liquid A and 0.8g of liquid B, and stir at a constant temperature of 95°C for 5 minutes; quickly add 1 mL of ethyl orthosilicate, and stir magnetically for 1 hour; mix 1 mL of ethyl orthosilicate and 2 mL of bis-[3-(triethoxy base silicon) propyl] tetrasulfide (BTES) after uniform mixing, quickly add the above solution, magnetic stirring for 4h, the product obtained after centrifugation of hierarchical porous mesoporous SiO 2 ball. Wash twice with ethanol, extract under the condition of hydrochloric acid ethanol for 6h (3 times) to remove the surfactant, wash twice with ethanol, and wash once with deionized water to obtain highly dispersed mesoporous SiO with hierarchical pores 2 particle.

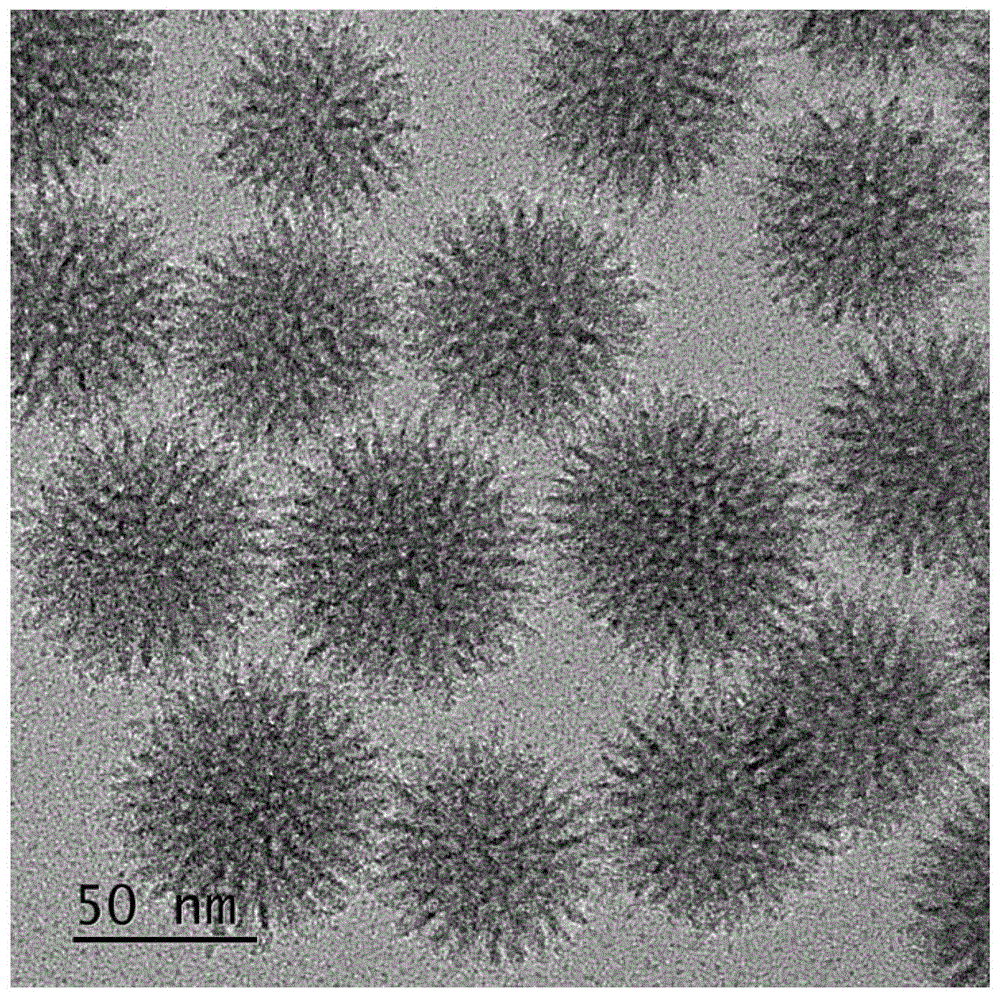

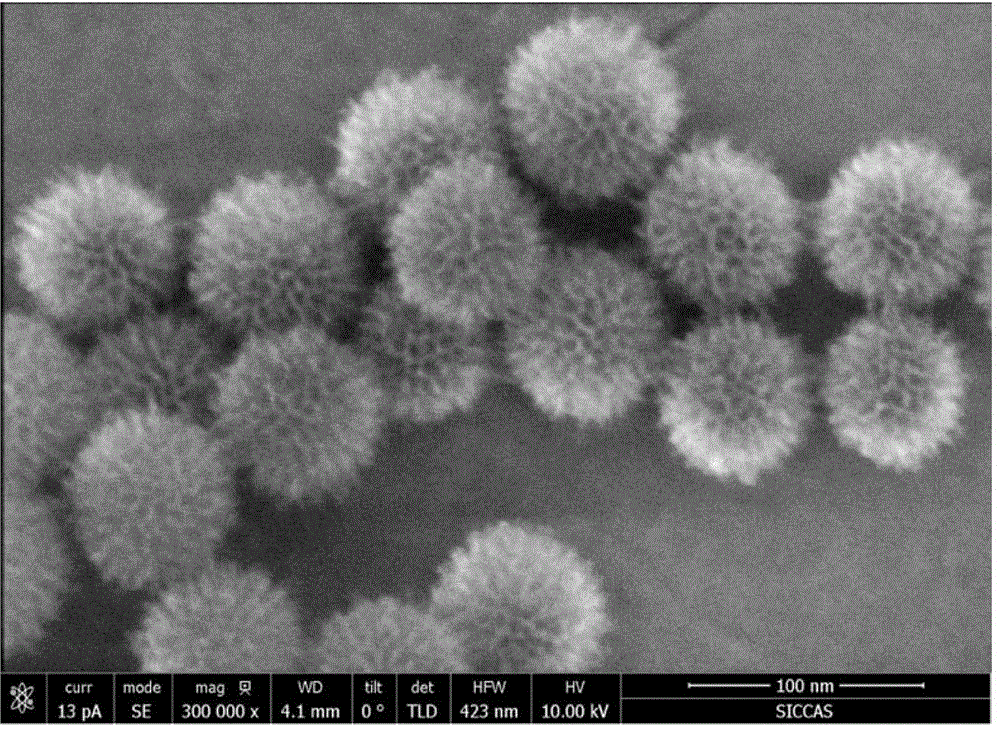

[0063] The SiO obtained in this example 2 The transmission electron microscope image of the particle is shown in figure 1 As shown...

Embodiment 2

[0065] Mix 45mL of deionized water and 5g of CTAC, and record it as solution A. Mix 9mL deionized water and 1gTEA, and record it as solution B. Mix 20g of liquid A and 0.8g of liquid B, and stir at a constant temperature of 95°C for 5 minutes; quickly add 1 mL of ethyl orthosilicate, and stir magnetically for 1 hour; mix 1 mL of ethyl orthosilicate and 1.3 mL of bis-[3-(triethyl Oxysilane)propyl]tetrasulfide (BTES) was uniformly mixed, then quickly added the above solution, magnetically stirred for 4h; ] Tetrasulfide (BTES) was mixed evenly, and the above solution was added rapidly, and magnetic stirring was continued for 4h. Hierarchical mesoporous SiO was obtained after the product was centrifuged 2 ball. Wash twice with ethanol, extract under the condition of hydrochloric acid ethanol for 6h (3 times) to remove the surfactant, wash twice with ethanol, and wash once with deionized water to obtain highly dispersed mesoporous SiO with hierarchical pores 2 particle.

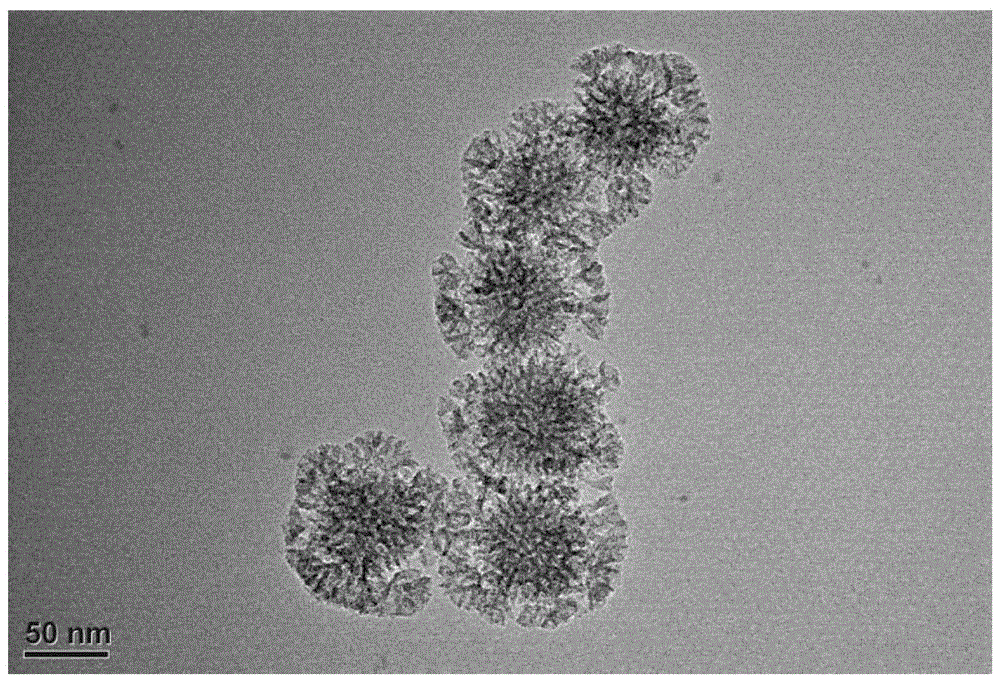

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com