A kind of preparation method of high-performance activated alumina ball

An activated alumina, high-performance technology, applied in chemical instruments and methods, alumina/aluminum hydroxide, inorganic chemistry, etc., can solve the problems affecting the product quality of alumina balls, poor strength of alumina balls, and shelling of alumina balls and other problems to achieve the effect of preventing shedding, improving quality, increasing specific surface area and pore volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

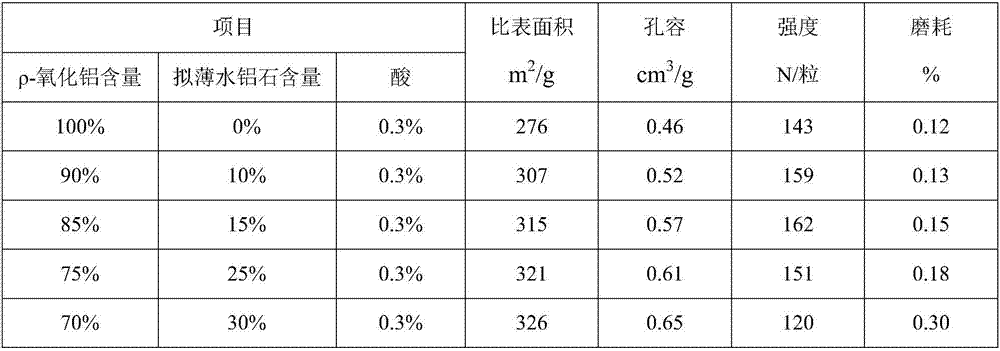

Embodiment 1

[0034] The rho-alumina and pseudo-boehmite prepared after the quick removal of aluminum hydroxide are added to a double-screw mixer and mixed evenly, the content of rho-alumina is 80% (%, mass fraction), and the pseudo-boehmite It is 20% (%, mass fraction). Among them, the pseudo-both alumina needs to be ground and sieved by a mechanical mill before being used. After sieving, the particle size can be adjusted according to production needs. Generally, the particle size of activated alumina balls is controlled at 325 mesh to 500 mesh. At the same time, a nitric acid solution with a concentration of 0.3% (%, mass fraction) was prepared for use.

[0035] The evenly mixed material of ρ-alumina powder and pseudo-boehmite powder is spirally and evenly put into the turntable ball forming machine from the feeding port, and the nitric acid solution is sprayed into the turntable of the turntable ball forming machine through the atomizing nozzle. Under the action of the centrifugal force...

Embodiment 2

[0040] Add the rho-alumina and pseudo-boehmite prepared after aluminum hydroxide quick removal into the twin-screw mixer, the content of rho-alumina is 75% (%, mass fraction), and the pseudo-boehmite is 25% % (%, mass fraction). Among them, the pseudo-both alumina needs to be ground and sieved by a mechanical mill before being used. After sieving, the particle size can be adjusted according to production needs. Generally, the particle size of activated alumina balls is controlled at 325 mesh to 500 mesh. At the same time, a citric acid solution of 0.5% (%, mass fraction) was prepared for use.

[0041] The mixed material of ρ-alumina powder and pseudo-boehmite powder is evenly put into the turntable ball forming machine by the feeding screw, and the citric acid solution is sprayed into the turntable through the atomizing nozzle. Under the action of the centrifugal force of the turntable, the rho-alumina powder and the pseudo-boehmite powder are bonded into green balls with a c...

Embodiment 3

[0043] Other parameters were the same as in Example 2, except that the acid solution was changed to acetic acid solution, and the concentration was 0.5% (%, mass fraction).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com