Biological functional inorganic dry powder coating and preparation method thereof

An inorganic dry powder and inorganic coating technology, applied in the field of architectural coatings, can solve problems such as harming human health and living environment, achieve excellent environmental protection, improve aging resistance, and purify the air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

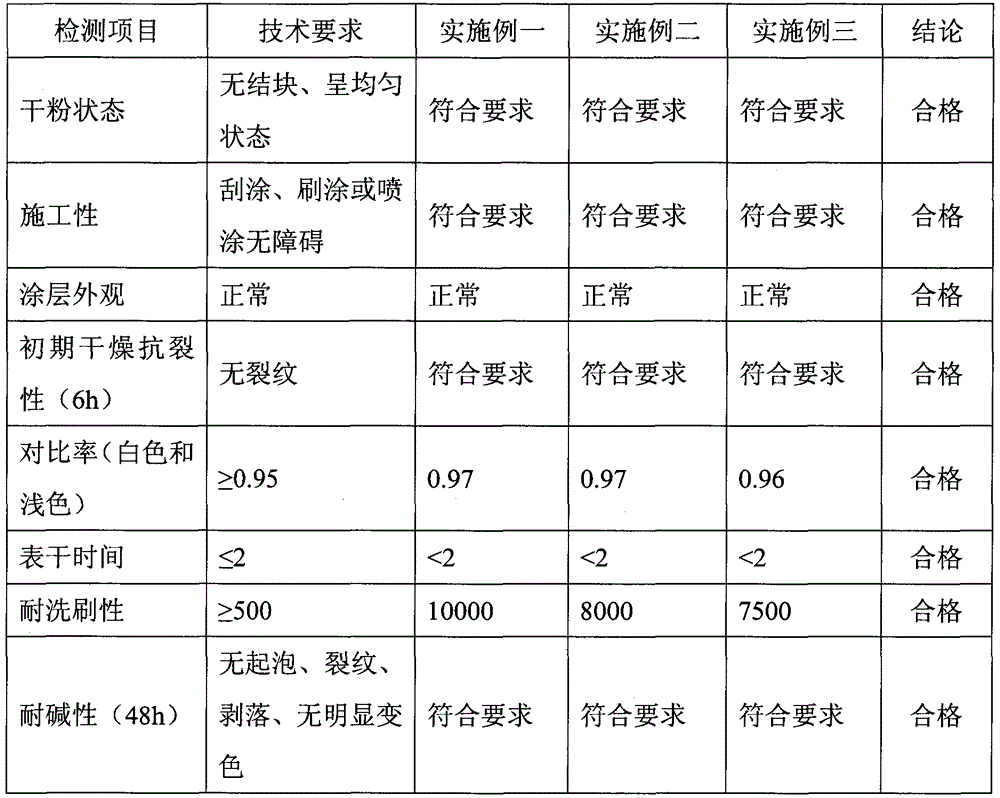

Examples

Embodiment 1

[0016] In terms of weight fractions, weigh 35 parts of white cement, 2.5 parts of nano-titanium dioxide, 15 parts of redispersible latex powder, 5 parts of titanium dioxide, 15 parts of glass fiber powder, 0.1 part of cellulose ether, 0.16 parts of defoamer, chlorinated Calcium 0.1 part, superplasticizer 0.06 part, sodium citrate 0.08 part, heavy calcium powder 15 parts, talcum powder 10 parts. Mix the above-mentioned inorganic paint and water according to the mass ratio of 1:0.35, stir evenly, let stand for 5 minutes, and carry out secondary stirring to carry out painting.

Embodiment 2

[0018] In terms of weight fractions, weigh 50 parts of white cement, 3 parts of nano-titanium dioxide, 10 parts of redispersible latex powder, 5 parts of titanium dioxide, 10 parts of glass fiber powder, 0.03 parts of cellulose ether, 0.1 part of defoamer, chlorinated 0.1 part of calcium, 0.05 part of water reducer, 0.08 part of sodium citrate, 20 parts of bentonite; mix all components evenly. At the request of the owner, 0.3-5 parts of inorganic pigments for coloring can also be added to the composition of the present invention. The performance of dry powder coatings remains consistent.

[0019] Mix the above-mentioned inorganic paint with water at a mass ratio of 1:0.5, stir evenly, let stand for 5 minutes, and then carry out secondary stirring to carry out spraying.

Embodiment 3

[0021] In terms of weight fraction, weigh 50 parts of white cement, 10 parts of redispersible latex powder, 5 parts of titanium dioxide, 10 parts of glass fiber powder, 0.03 part of cellulose ether, 0.1 part of defoamer, 0.1 part of calcium chloride, and 0.05 parts of water, 0.08 parts of sodium citrate, 20 parts of bentonite.

[0022] Mix the above inorganic paint and water according to the mass ratio of 1:0.4, stir evenly, let it stand for 5 minutes, and then carry out the second stirring to paint the first time, then weigh 2 parts of nano-titanium dioxide and add it to the paste mixture, stir well After uniformity, paint a second time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com