Method for preparing anti-pathogenic active oleanane glycoside through chemical conversion

An oleanane-type, anti-pathogenic technology is applied in the field of biocidal active substances to achieve the effects of good environmental compatibility, prevention of pathogen adhesion, and strong foaming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

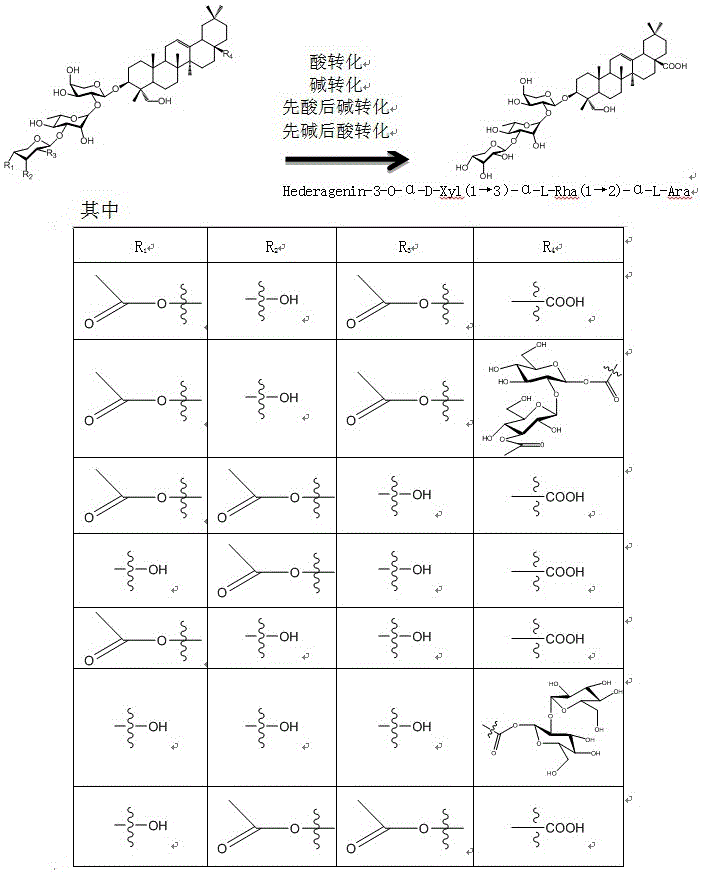

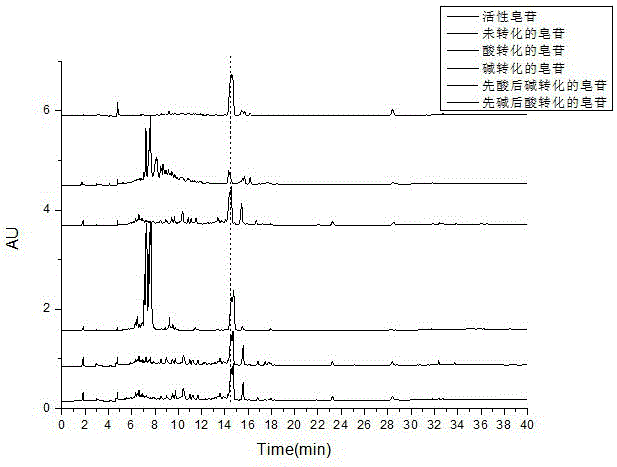

Method used

Image

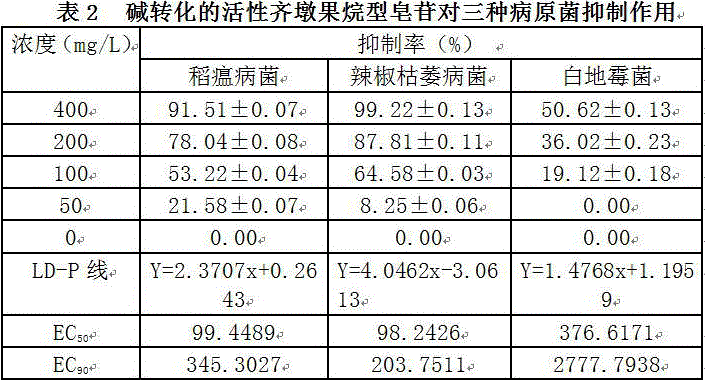

Examples

Embodiment 1

[0029]1. Extraction of Sapindus crude saponin: remove the husk and core of Sapindia fruit, air-dry the mesocarp at room temperature, weigh 10kg, add 50kg of 70% ethanol aqueous solution to soak for 20 hours, extract in 70°C water bath for 5 hours, and suction filter. Recover the ethanol solvent under reduced pressure and concentrate to obtain about 6kg of crude saponin extract (standby);

[0030] 2. Acid-converted crude saponin extract: slowly add 10 mL of 2 M hydrochloric acid solution to 5 kg of crude saponin extract to obtain a mixed saponin aqueous solution, and adjust with water to obtain a final concentration of hydrochloric acid in the mixed saponin aqueous solution of 0.1 M. Hydrolyzed for 18 hours to obtain active oleanane triosyl saponins;

[0031] 3. Deacidification and concentration of active oleanane-type saponins: Pour the active oleanane trisaccharide-based saponins into the D101 macroporous resin column until the breakthrough point, let the D101 macroporous res...

Embodiment 2

[0035] 1. Crude saponin extraction of Sapindus chinensis: Sapindia chinensis fruit, shell and core removed, mesocarp air-dried at room temperature, weighing 20kg, adding 160kg of 80% ethanol aqueous solution to soak for 24 hours, leaching in 90℃ water bath for 10 hours, and suction filtration , recover the ethanol solvent under reduced pressure and concentrate to obtain about 8kg crude saponin extract (for standby);

[0036] 2. Alkali-transformed crude saponin extract: slowly add 10 mL of 2 M sodium hydroxide solution to 5 kg of crude saponin extract to obtain a mixed saponin aqueous solution, and adjust the final concentration of sodium hydroxide in the mixed saponin aqueous solution to 0.5 M with water. Hydrolyze at 90°C for 24 hours to obtain active oleanane triosyl saponins;

[0037] 3. Dealkalization and concentration of active oleanane-type saponins: Pour the active oleanane trisaccharide-based saponins into the D101 macroporous resin column until the breakthrough point,...

Embodiment 3

[0041] 1. Crude saponin extraction of Sapindus chinensis: Sapindia chinensis fruit, remove husk and core, air-dry mesocarp at room temperature, weigh 6kg, add 30kg of 60% ethanol aqueous solution to soak for 12h, leaching at 60°C for 3h, suction filtration, and decompression Recover the ethanol solvent and concentrate to obtain about 4kg crude saponin extract (standby);

[0042] 2. Convert the crude saponin extract to acid and then alkali: slowly add 0.5 mL of 2 M hydrochloric acid solution to 4 kg of crude saponin extract to obtain a mixed saponin aqueous solution, and adjust the final concentration of hydrochloric acid in the mixed saponin aqueous solution to 0.1 M with water, 60 After hydrolysis for 12 h at ℃, adjust the final concentration of sodium hydroxide in the mixed saponin aqueous solution to 0.5 M with 2 M sodium hydroxide solution, and hydrolyze for 12 h at 60 °C to obtain active oleanane triosyl saponin;

[0043] 3. Concentrated active oleanane triose-based sapon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com