Anti-impact material and preparation method thereof

An impact-resistant, polystyrene microsphere technology, applied in the field of polymer materials, can solve the problems of poor impact resistance, inability to protect against impact, and inability to absorb impact energy well, and achieve the effect of excellent impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

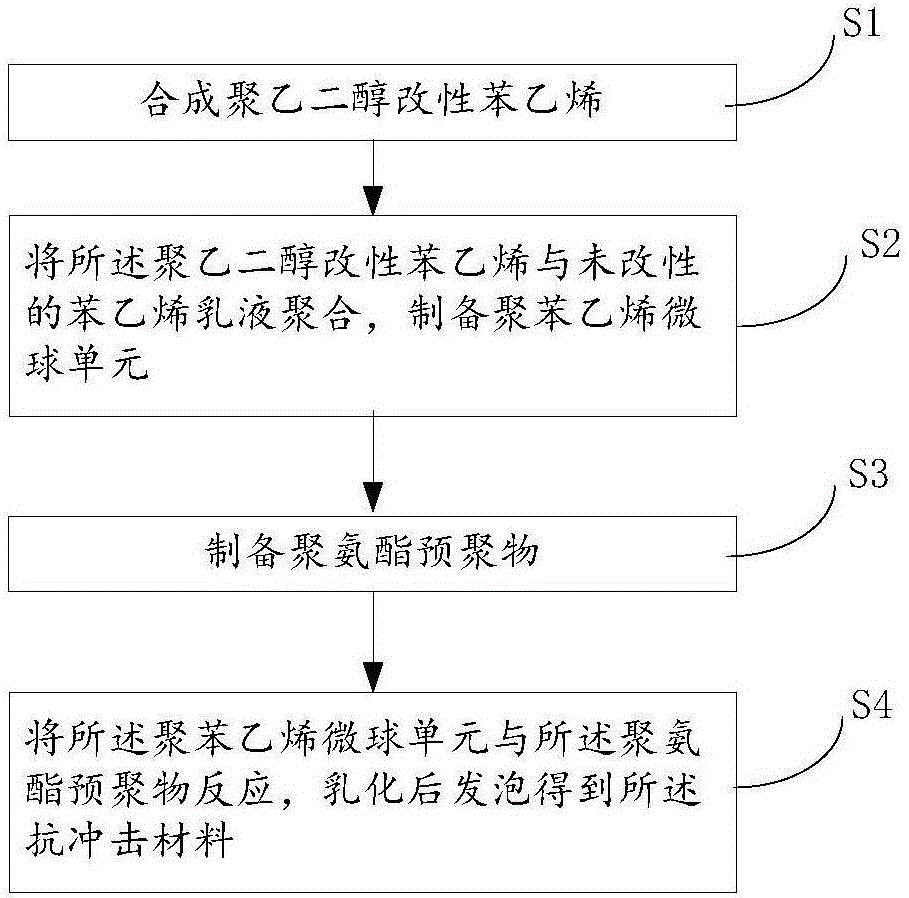

[0031] see figure 2 , the present invention also provides a kind of preparation method of above-mentioned polyurethane composite material 100, and described preparation method comprises the following steps:

[0032] S1: Synthesis of polyethylene glycol-modified styrene.

[0033] Specifically, in the embodiment of the present invention, the chemical structure of polyethylene glycol-modified styrene is preferably: Further, in the embodiment of the present invention, the polyethylene glycol-modified styrene is prepared by esterifying methyl vinyl benzoate and polyethylene glycol. Specifically, the molar ratio of methyl vinyl benzoate to polyethylene glycol is 0.9:1, adding a small amount of potassium hydroxide as a catalyst, reacting at 60°C for 2-4 hours, distilling under reduced pressure, washing repeatedly, and drying in vacuo A polyethylene glycol-modified styrene monomer is obtained.

[0034] S2: Emulsion polymerizing the polyethylene glycol-modified styrene with unmodi...

Embodiment 1

[0051] Add 100g of methyl vinyl benzoate and 1.5% catalyst KOH into a 500ml three-necked flask, raise the temperature to 60°C, gradually add 400g of polyethylene glycol dropwise to the solution, react for 2 hours, distill under reduced pressure and wash repeatedly, vacuum Dry to obtain polyethylene glycol modified styrene.

[0052] Sodium dodecylsulfonate is used as emulsifier, potassium persulfate is used as catalyst, polyethylene glycol modified styrene and unmodified styrene are emulsion polymerized, each 50g. The mass fraction of the monomer is 5%, the mass fraction of the emulsifier is 0.2%, and the mass fraction of the catalyst is 0.2%. Polyethylene glycol-modified styrene and unmodified styrene were gradually added dropwise to an aqueous solution containing a catalyst and an emulsifier, and reacted at 85° C. for 2 hours to obtain polystyrene microspheres containing polar group terminals.

[0053] Dry 50g of polyethylene glycol in vacuum, add nitrogen into a 250ml three...

Embodiment 2

[0057] Add 100g of methyl vinyl benzoate and 1.5% catalyst KOH into a 500ml three-necked flask, raise the temperature to 60°C, gradually add polyethylene glycol 400 to the solution dropwise, react for 4 hours, distill under reduced pressure and wash repeatedly, vacuum Dry to obtain polyethylene glycol modified styrene.

[0058] Using sodium dodecylsulfonate as an emulsifier and potassium persulfate as a catalyst, 40 g of polyethylene glycol-modified styrene and 60 g of unmodified styrene were emulsion polymerized. The mass fraction of the monomer is 10%, the mass fraction of the emulsifier is 0.2%, and the mass fraction of the catalyst is 0.2%. Polyethylene glycol-modified styrene and unmodified styrene were gradually added dropwise to an aqueous solution containing a catalyst and an emulsifier, and reacted at 60° C. for 2 hours to obtain polystyrene microspheres containing polar group terminals.

[0059] Vacuum dry 50g of polyethylene glycol, add nitrogen into a 250ml three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com