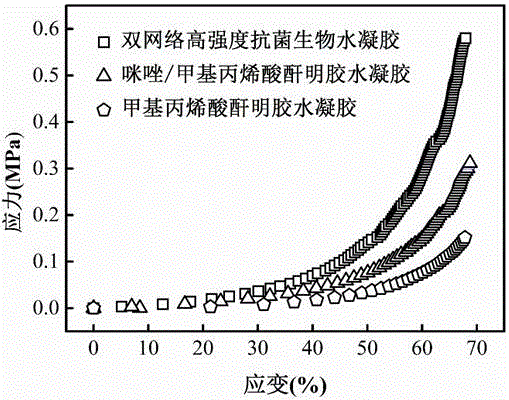

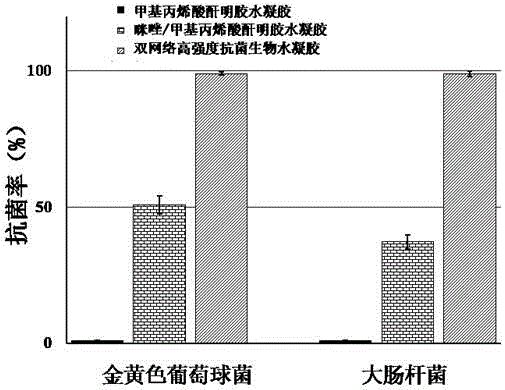

Preparation method of high strength double-network antibacterial biological hydrogel

A hydrogel and dual network technology, applied in the field of biomedical hydrogel synthesis, can solve the problems of limited hydrogel application, poor mechanical properties, easy to be infected by bacteria, etc., achieving good mechanical properties, improved toughness, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033](1) Weigh 5g of gelatin into 50ml of phosphate buffer solution, stir and dissolve at 40°C; take 2ml of methacrylic anhydride, slowly add it dropwise to the above solution, and stir for 2 hours; pour the reacted mixture into 40 In the phosphate buffer solution at ℃, stir for 2 minutes to terminate the reaction; use a dialysis bag to pack the above liquid, and dialyze in deionized water at 40 ℃ for 6 days; divide the dialyzed solution with a centrifuge tube and centrifuge to collect the supernatant , stored in an ultra-low temperature refrigerator for 24 hours, and then freeze-dried in a freeze dryer to obtain a high-purity methacrylic anhydride gelatin sample.

[0034] (2) Weigh 3g of histidine and dissolve it in 7ml of sodium hydroxide solution, pass through nitrogen and dissolve in an ice bath; take 1.5ml of acryloyl chloride, and slowly add it dropwise to the above solution under nitrogen atmosphere and dark conditions ; After maintaining the reaction at 0°C for 30 min...

Embodiment 2

[0040] (1) Weigh 5g of gelatin into 50ml of phosphate buffer solution, stir and dissolve at 50°C; take 3ml of methacrylic anhydride, slowly add it dropwise to the above solution, stir and react for 3h; pour the reacted mixture into 50 In the phosphate buffer solution at ℃, stir for 2 minutes to stop the reaction; use a dialysis bag to pack the above liquid, and dialyze it in deionized water at 50 ℃ for 8 days; divide the dialyzed solution with a centrifuge tube and centrifuge to collect the supernatant , stored in an ultra-low temperature refrigerator for 24 hours, and then freeze-dried in a freeze dryer to obtain a high-purity methacrylic anhydride gelatin sample.

[0041] (2) Weigh 3g of histidine and dissolve it in 7ml of sodium hydroxide solution, pass through nitrogen and dissolve in an ice bath; take 1.7ml of acryloyl chloride, and slowly add it dropwise to the above solution under nitrogen atmosphere and dark conditions ; After keeping the reaction at 2°C for 40 minutes...

Embodiment 3

[0048] (1) Weigh 5g of gelatin into 50ml of phosphate buffer solution, stir and dissolve at 60°C; take 4ml of methacrylic anhydride, slowly add it dropwise to the above solution, and stir for 4 hours; pour the reacted mixture into 60 Phosphate buffer solution at ℃, stirred for 2 min, and the reaction was terminated; the above liquid was divided into dialysis bags, and dialyzed in deionized water at 60 °C for 10 days; the dialyzed solution was divided into centrifuge tubes and centrifuged, and the supernatant was collected. Freeze in an ultra-low temperature refrigerator for 24 hours, and then freeze-dry in a freeze dryer to obtain a high-purity methacrylic anhydride gelatin sample.

[0049] (2) Weigh 3g of histidine and dissolve it in 7ml of sodium hydroxide solution, pass through nitrogen and dissolve in an ice bath; take 1.8ml of acryloyl chloride, and slowly add it dropwise to the above solution under nitrogen atmosphere and dark conditions ; After keeping the reaction at 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fracture stress | aaaaa | aaaaa |

| Fracture stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com