Antifreeze PVC material and preparation method thereof

A PVC material and PVC resin technology, applied in the field of pipe fitting materials, can solve the problems of poor frost resistance, poor low temperature resistance, easy deformation, etc., achieve excellent low temperature resistance, excellent comprehensive performance, and improve cold resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

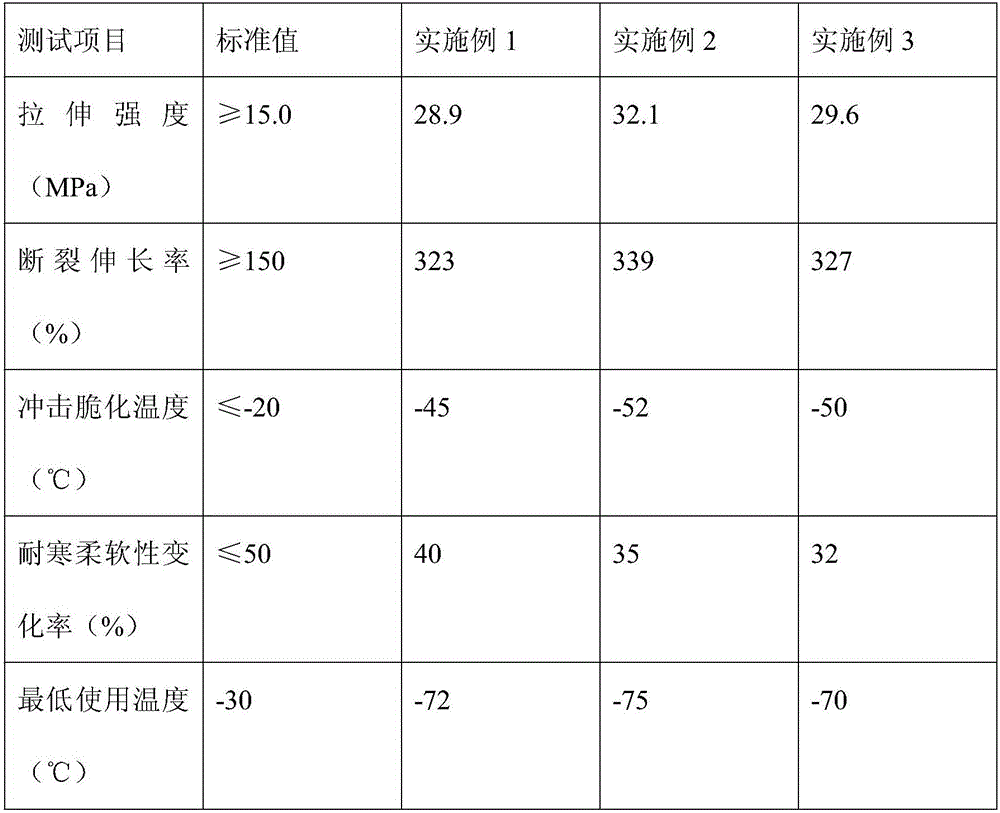

Examples

Embodiment 1

[0018] An antifreeze PVC material, which is composed of the following raw materials in parts by weight: 100 parts of PVC resin, 10 parts of magnesium stearate, 2 parts of polyimide particles, 10 parts of colloidal calcium carbonate, 10 parts of diatomaceous earth, polyethylene 3 parts of imine, 5 parts of epoxy soybean oil, 5 parts of polymethyl acrylate latex powder, 1 part of polyammonium methacrylate, 4 parts of epoxy resin, 2 parts of dioctyl adipate, 10 parts of carbon fiber, ethyl acetate 5 parts of ester, 3 parts of butadiene rubber, 4 parts of chlorinated polyethylene, 0.3 parts of lubricant.

[0019] The preparation method of the antifreeze PVC material comprises the following preparation steps:

[0020] (1) take raw material by above-mentioned parts by weight;

[0021] (2) Heat magnesium stearate to 140°C, then add polyimide particles, colloidal calcium carbonate, and diatomaceous earth, stir evenly, and obtain modified powder after cooling; then add polyethyleneimi...

Embodiment 2

[0027] An antifreeze PVC material, which is composed of the following raw materials in parts by weight: 110 parts of PVC resin, 12 parts of magnesium stearate, 3 parts of polyimide particles, 9 parts of colloidal calcium carbonate, 12 parts of diatomaceous earth, polyethylene 4 parts of imine, 10 parts of epoxy soybean oil, 8 parts of polymethyl acrylate latex powder, 2 parts of polyammonium methacrylate, 3 parts of epoxy resin, 3 parts of dioctyl adipate, 12 parts of carbon fiber, ethyl acetate 7 parts of ester, 5 parts of butadiene rubber, 5 parts of chlorinated polyethylene, 0.8 parts of lubricant.

[0028] The preparation method of the antifreeze PVC material comprises the following preparation steps:

[0029] (1) take raw material by above-mentioned parts by weight;

[0030] (2) Heat magnesium stearate to 145°C, then add polyimide particles, colloidal calcium carbonate, and diatomaceous earth, stir evenly, and obtain modified powder after cooling; then add polyethyleneim...

Embodiment 3

[0036] An antifreeze PVC material, which is composed of the following raw materials in parts by weight: 120 parts of PVC resin, 15 parts of magnesium stearate, 4 parts of polyimide particles, 8 parts of colloidal calcium carbonate, 15 parts of diatomaceous earth, polyethylene 5 parts of imine, 15 parts of epoxy soybean oil, 10 parts of polymethyl acrylate latex powder, 3 parts of polyammonium methacrylate, 4 parts of epoxy resin, 4 parts of dioctyl adipate, 15 parts of carbon fiber, ethyl acetate 8 parts of ester, 6 parts of butadiene rubber, 6 parts of chlorinated polyethylene, 1.5 parts of lubricant.

[0037] The preparation method of the antifreeze PVC material comprises the following preparation steps:

[0038] (1) take raw material by above-mentioned parts by weight;

[0039] (2) Heat magnesium stearate to 150°C, then add polyimide particles, colloidal calcium carbonate, and diatomaceous earth, stir evenly, and obtain modified powder after cooling; then add polyethylenei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com