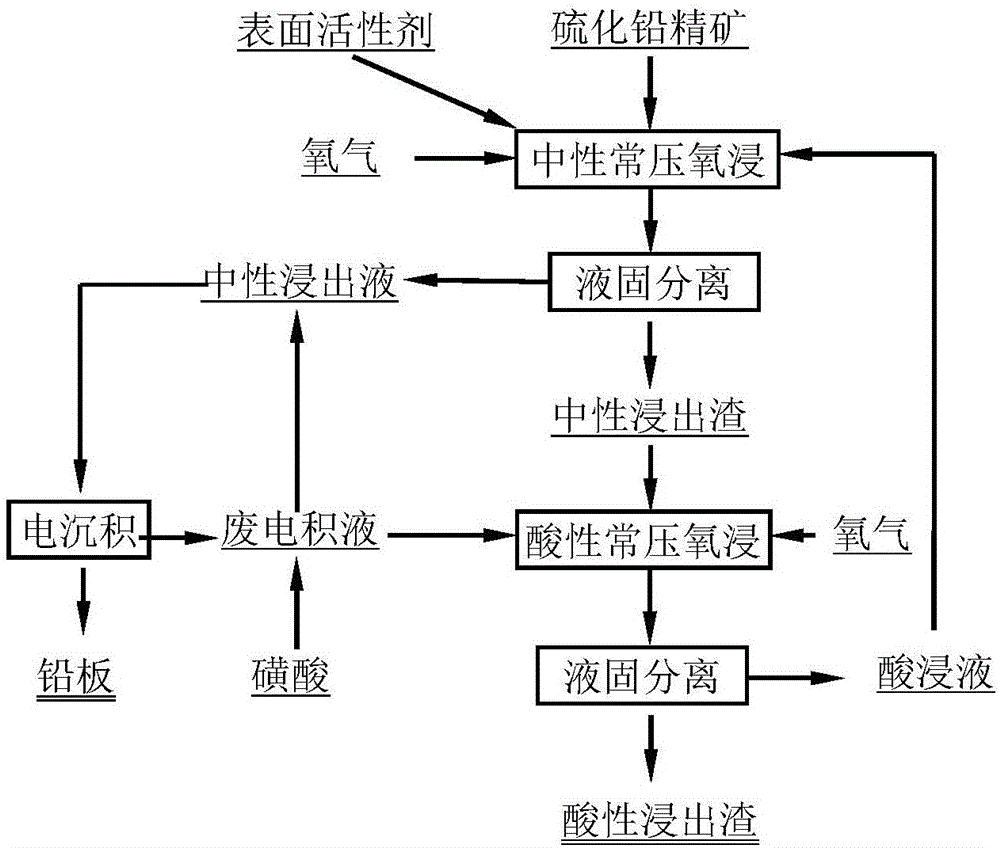

Method for extracting lead from lead sulfide concentrate through two-stage countercurrent constant-pressure oxidizing leaching of sulfonic acid solution

A lead sulfide and acid leaching technology, applied in the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of poor operating environment, serious environmental pollution, and high corrosiveness of leaching agents, so as to achieve low corrosiveness and avoid environmental pollution. , the effect of low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The chemical composition of the lead sulfide concentrate used in the test is shown in Table 1.

[0048] Table 1 Chemical composition of lead sulfide concentrate

[0049] element Pb S Fe Ag Element / % 48.71 17.32 7.76 0.0057

[0050] Get 400g of lead sulfide concentrate (its chemical composition is shown in Table 1), add acidic leaching solution 2000mL, its chemical composition is: Pb 2+ 120g / L, the total concentration of iron ions is 0.15mol / L, and the concentration of free methanesulfonic acid is 0.3mol / L; and add 0.5g calcium lignosulfonate, in a cylindrical reactor with a diameter of 10cm, stir while stirring Oxygen is blown into the bottom of the paddle, the stirring speed is 350r / min, and the reaction is carried out at a temperature of 95°C for 20h until the pH value of the solution is 5.3 and the total concentration of iron ions is less than 5mg / L, then the neutral leachate and neutral leach residue are separated.

[0051] Neutral le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com