Aluminium alloy for preparing mobile phone housing, and preparation method thereof

A mobile phone shell and aluminum alloy technology, applied in the field of aluminum alloy, can solve the problems affecting the safety and service life of mobile phones, the influence of mobile phone communication and networking, and the strong signal shielding effect, so as to enhance mechanical strength and thermal conductivity, and improve electronic activity. The effect of enhanced capability, mechanical strength and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing an aluminum alloy for a mobile phone casing, comprising:

[0030] Weigh the raw materials in proportion, melt the raw materials in the container, pass the inert gas preheated for 2-3 minutes into the melt from the bottom of the container and let it stand for 30-40 minutes to make the scum fully float on the surface, remove the scum and keep it warm Stand still for 10-20 minutes, and cast to obtain an aluminum alloy ingot.

[0031] The aluminum alloy ingot is subjected to hot extrusion treatment, quenching treatment and aging treatment in sequence; the temperature of hot extrusion treatment is 345-355°C, and the speed is 0.5-0.8m / min; the temperature of quenching treatment is 480-510°C; The temperature of the treatment is 165-180°C.

[0032] More preferably, when feeding raw materials, first add pure aluminum ingots to the smelting furnace, raise the temperature to about 600°C, and then gradually raise the temperature to about 700°C at a heating r...

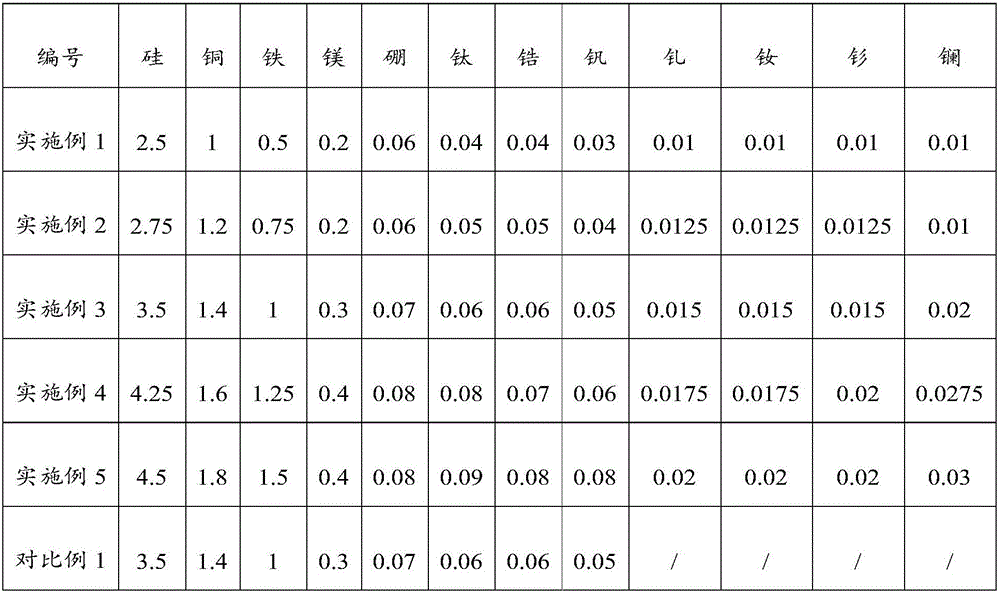

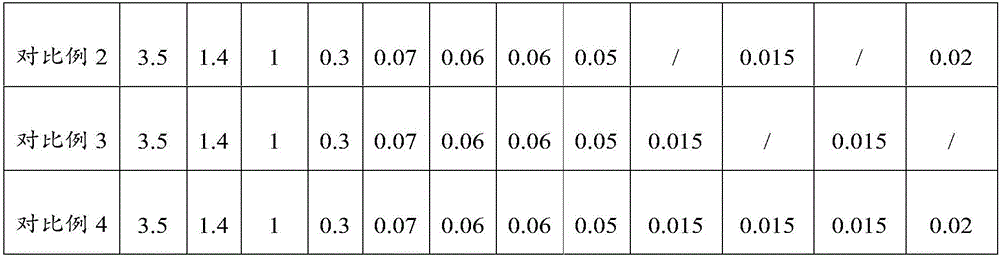

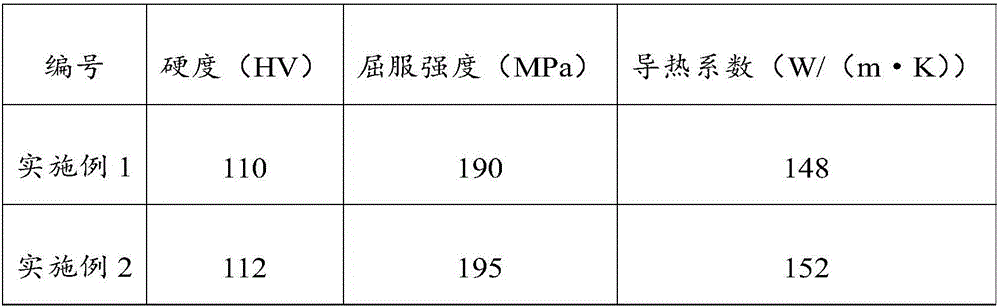

Embodiment 1

[0041] A method for preparing an aluminum alloy for a mobile phone casing, comprising:

[0042] Aluminum alloy raw materials were prepared according to the composition in Table 1, and the raw materials were melted in a container to obtain a melt. Inject the inert gas preheated for 2 minutes from the bottom of the container into the melt and let it stand for 30 minutes to make the scum fully float on the surface of the aluminum alloy liquid, remove the scum and let it stand for 10 minutes, then cast the formed aluminum alloy ingot. The aluminum alloy ingot was hot extruded at a temperature of 345° C. at an extrusion speed of 0.5 m / min. Heat the aluminum alloy ingot after hot extrusion treatment to 480°C and keep it warm for 10 minutes; cool the heat-preserved aluminum alloy ingot to 300°C within 5 minutes, and then cool it down to room temperature at a cooling rate of 10°C / min to complete quenching deal with. The quenched aluminum alloy ingot was heated to 165° C. and kept fo...

Embodiment 2

[0044] A method for preparing an aluminum alloy for a mobile phone casing, comprising:

[0045] Aluminum alloy raw materials were prepared according to the composition in Table 1, and the raw materials were melted in a container to obtain a melt. Inject the inert gas preheated for 2 minutes from the bottom of the container into the melt and let it stand for 30 minutes to make the scum fully float on the surface of the aluminum alloy liquid, remove the scum and let it stand for 10 minutes, then cast the formed aluminum alloy ingot. The aluminum alloy ingot was hot extruded at a temperature of 345° C. at an extrusion speed of 0.5 m / min. Heat the aluminum alloy ingot after hot extrusion treatment to 490°C and keep it warm for 10 minutes; cool the heat-preserved aluminum alloy ingot to 315°C within 4 minutes, and then cool it down to room temperature at a cooling rate of 10°C / min to complete quenching deal with. The quenched aluminum alloy ingot was heated to 165° C. and kept fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com