Energy-saving environment-friendly baking equipment

A technology for baking equipment, energy saving and environmental protection, which is applied in the direction of heat storage equipment, combustion equipment, lighting and heating equipment, etc. It can solve the problems of short service life, poor heat preservation, poor sturdiness, etc., and achieve improved efficiency, stable temperature, and guaranteed heat The effect of the supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

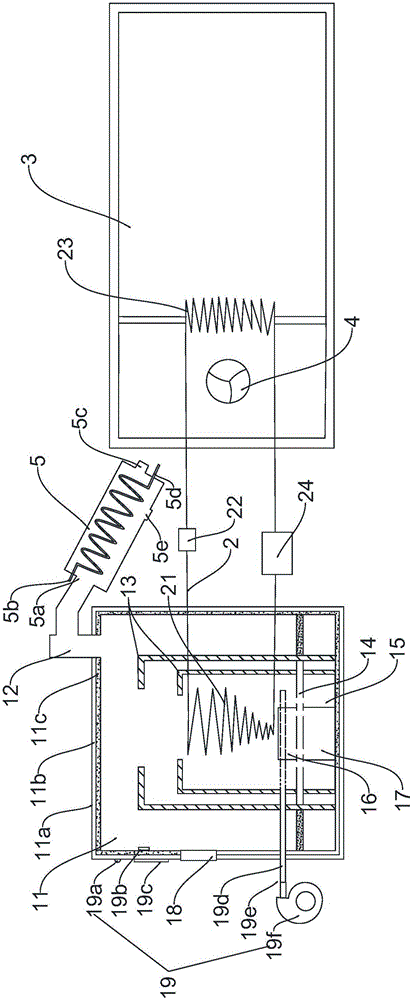

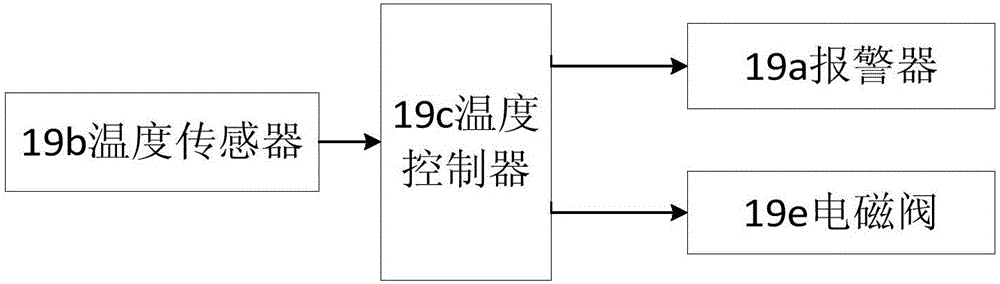

Method used

Image

Examples

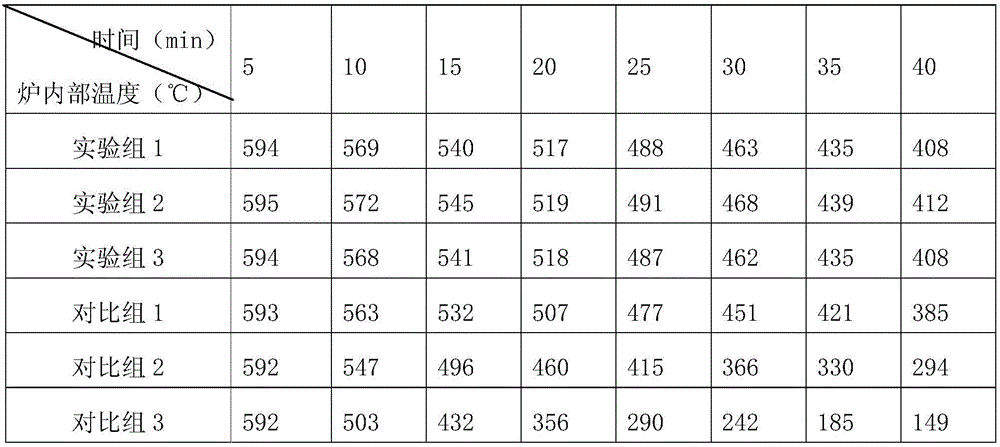

Embodiment 1

[0036] A heat storage brick used in a heat storage heat preservation boiler is made by mixing the following raw materials according to the weight ratio: high alumina 25kg, aluminum silicate 25kg, zirconium phosphate 20kg, boron carbide 10kg, silicon nitride 8kg, Titanium dioxide 2kg, magnesia clay 6kg, water 4kg. Among them, the particle size of the high alumina is required to be 0.1-1mm, and the content of aluminum oxide in the high alumina is more than 65%.

[0037] The above-mentioned heat storage brick is made by the following method: prepare raw materials according to the weight ratio; mix high alumina, aluminum silicate, zirconium phosphate, boron carbide, silicon nitride, and titanium dioxide evenly to form a premix; mix water, magnesium The clay is mixed evenly and then added to the premix. After mixing evenly, it is pressed under a pressure of 1.5Mpa. After drying at 120°C for 24 hours, it is placed in a high-temperature kiln and sintered at 1200-1300°C. The sintering...

Embodiment 2

[0039] A heat storage brick used in a heat storage heat preservation boiler is made by mixing the following raw materials according to the weight ratio: high alumina 30kg, aluminum silicate 20kg, zirconium phosphate 15kg, boron carbide 6kg, silicon nitride 9kg, Titanium dioxide 3kg, magnesia clay 10kg, water 6kg. Among them, the particle size of the high alumina is required to be 0.1-1mm, and the content of aluminum oxide in the high alumina is more than 65%.

[0040] The above-mentioned heat storage brick is made by the following method: prepare raw materials according to the weight ratio; mix high alumina, aluminum silicate, zirconium phosphate, boron carbide, silicon nitride, and titanium dioxide evenly to form a premix; mix water, magnesium The clay is mixed evenly and then added to the premix. After mixing evenly, it is pressed under a pressure of 1.8Mpa. After drying at 150°C for 20 hours, it is placed in a high-temperature kiln and sintered at 1200-1300°C. The sintering...

Embodiment 3

[0042] A heat storage brick used in a heat storage heat preservation boiler is made by mixing the following raw materials according to the weight ratio: high alumina 28kg, aluminum silicate 22kg, zirconium phosphate 16kg, boron carbide 8kg, silicon nitride 11kg, Titanium dioxide 3kg, magnesia clay 7kg, water 5kg. Among them, the particle size of the high alumina is required to be 0.1-1mm, and the content of aluminum oxide in the high alumina is more than 65%.

[0043] The above-mentioned heat storage brick is made by the following method: prepare raw materials according to the weight ratio; mix high alumina, aluminum silicate, zirconium phosphate, boron carbide, silicon nitride, and titanium dioxide evenly to form a premix; mix water, magnesium The clay is mixed evenly and then added to the premix. After mixing evenly, it is pressed under a pressure of 1.6Mpa. After drying at 130°C for 22 hours, it is placed in a high-temperature kiln and sintered at 1200-1300°C. The sintering...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap