Photoresist and application method thereof

An application method and photoresist technology, applied in the fields of electronic information technology and biomedicine, can solve the problems of great harm to the human body, poor environmental friendliness, poor biocompatibility and degradability, etc., and achieve excellent mechanical properties and biological phase. Good capacitance and good etch selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

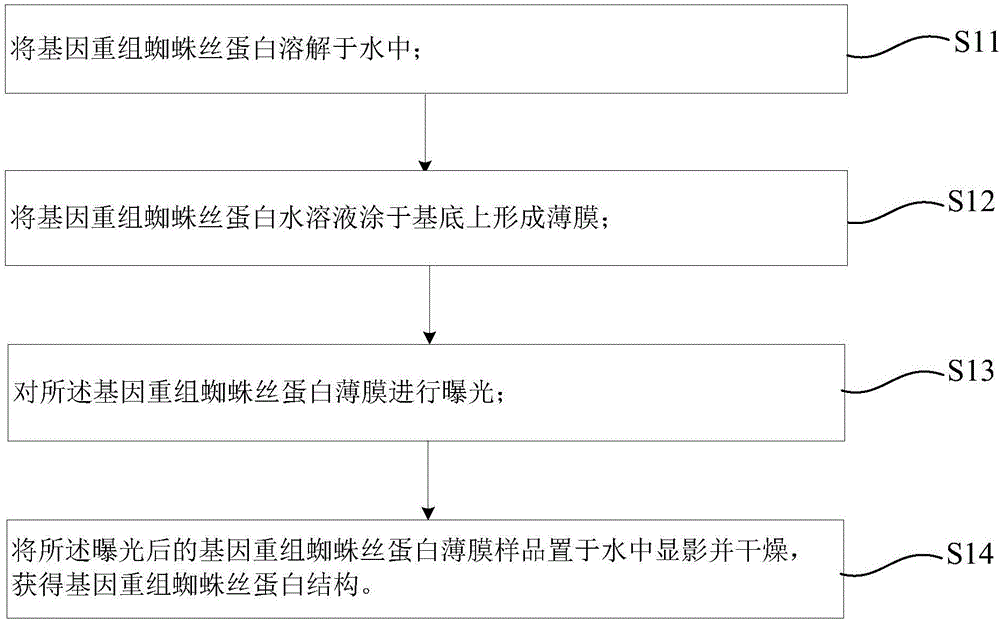

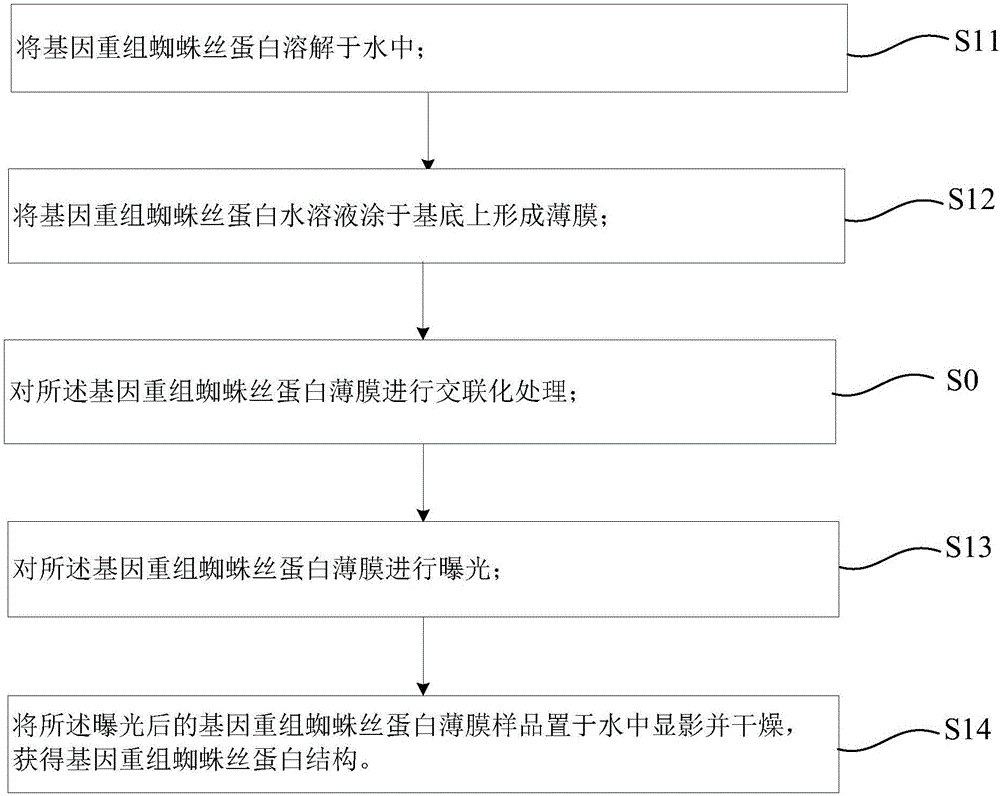

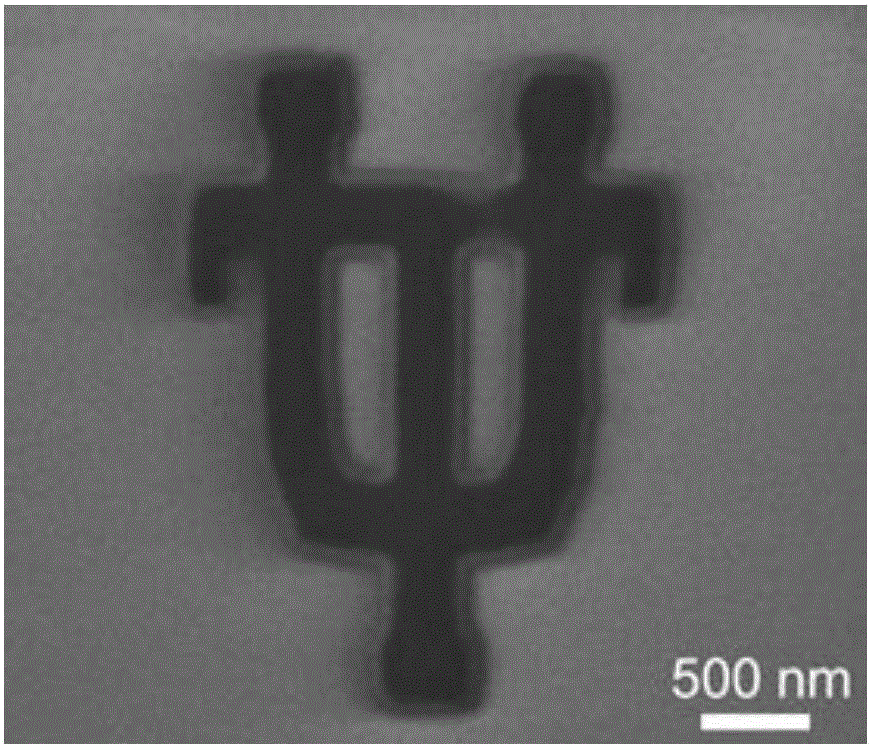

[0037] This embodiment provides a method for applying a photoresist, and the photoresist is a genetically recombinant spider silk protein MaSp1. In this embodiment, the photoresist is processed by electron beam exposure, image 3 with Figure 4 It is a scanning electron micrograph of the processed genetically recombined spider silk protein structure, wherein image 3 For positive glue, Figure 4 For negative glue, the specific steps are:

[0038] First, step S1 is performed, dissolving the recombinant spider silk protein in water to form an aqueous solution of the recombinant spider silk protein.

[0039] In this embodiment, the genetically recombinant spider silk protein has a molecular weight of 125 KDa and is a solid powder, the water is ultrapure water, and the resistivity is 18.25 MΩ·cm.

[0040]Executing step S2, providing a substrate, coating the aqueous solution of the genetically recombined spider silk protein on the substrate, drying and curing to form a genetica...

Embodiment 2

[0049] This embodiment provides a method for applying a photoresist, and the photoresist is a genetically recombinant spider silk protein MaSp2. In this embodiment, the photoresist is processed by ion beam exposure. Figure 5 with Image 6 It is a scanning electron micrograph of the processed genetically recombined spider silk protein structure, wherein Figure 5 For positive glue, Image 6 For negative glue, the specific steps are:

[0050] First, step S1 is performed, dissolving the recombinant spider silk protein in water to form an aqueous solution of the recombinant spider silk protein.

[0051] In this embodiment, the genetically recombinant spider silk protein has a molecular weight of 100 KDa and is a solid powder, the water is ultrapure water, and the resistivity is 18.25 MΩ·cm.

[0052] Execute step S2, coating the aqueous solution of gene recombinant spider silk protein on the substrate, drying and curing to form a gene recombinant spider silk protein film.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com