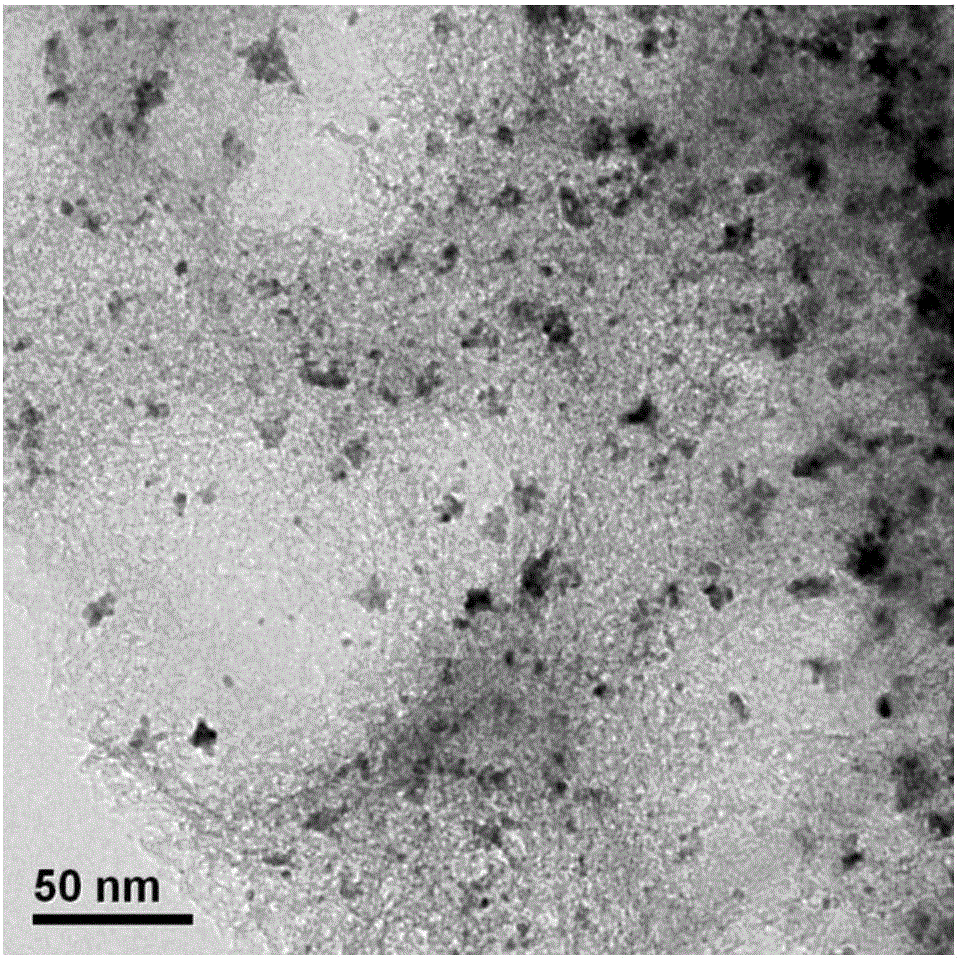

Preparation of lithium ion battery taking graphene loaded nano titanium dioxide as cathode material

A nano-titanium dioxide, lithium-ion battery technology, applied in secondary batteries, electrolyte battery manufacturing, nanotechnology and other directions, can solve serious problems, particle agglomeration, difficult product quality control and other problems, achieve high hydrogen overpotential, eliminate hydrogen generation, The effect of safe and reliable high-energy power battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1: Preparation of NaCl-KCl eutectic salt

[0058] Add NaCl (45g) and KCl (55g) into a ball mill jar, mill at a speed of 700rpm for 1 hour, take it out and put it in a crucible, heat it in air at 700°C for 2 hours, and cool it to 25°C to obtain NaCl-KCl eutectic salt.

Embodiment 2

[0059] Example 2: Preparation of carbon-supported nano-boron-lithium alloy

[0060] Take glucose monohydrate (4g), add glucose monohydrate, urea and lithium metaborate in a ball mill tank at a mass ratio of 4:2:1, and ball mill at a speed of 700rpm for 2 hours to prepare a carbon-supported nano boron-lithium alloy precursor ;

[0061] After heating to 110°C for 2 hours under a nitrogen atmosphere, vacuumize and heat to 440°C for 8 hours, then heat to 900°C for 2 hours, and the heating rate for three times is 10°C / min; cool to room temperature to obtain carbon Nano boron-lithium alloy loaded.

Embodiment 3

[0062] Embodiment three: the preparation of negative electrode

[0063] Get the Nafion solution (1g) of the carbon-loaded nano boron-lithium alloy (0.85g), acetylene black (0.1g) and commercially available mass content 5wt% that make in embodiment two, the graphene is loaded with nano-boron-lithium alloy, Acetylene black and Nafion solution are mixed and ground according to the mass ratio of 85:10:100, prepared into a paste and then applied to commercially available nickel foam; 2 Press molding under a certain pressure to obtain a negative electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com