Nitride mode locking echo wall microlaser and preparation method thereof

A technology of micro-laser and nitride, which is applied in the field of laser to achieve the effect of high optical gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

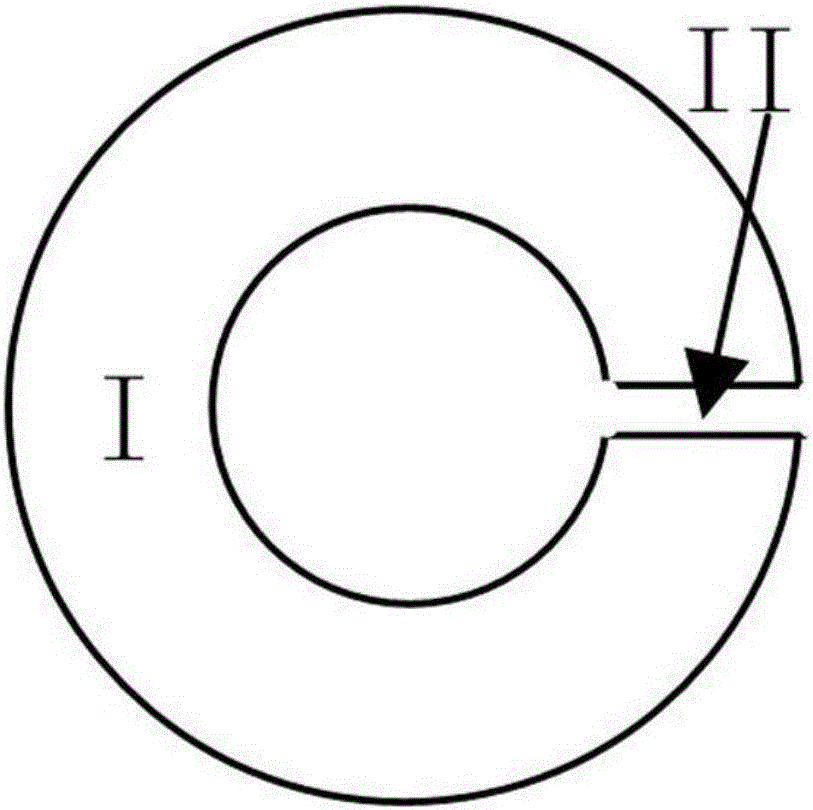

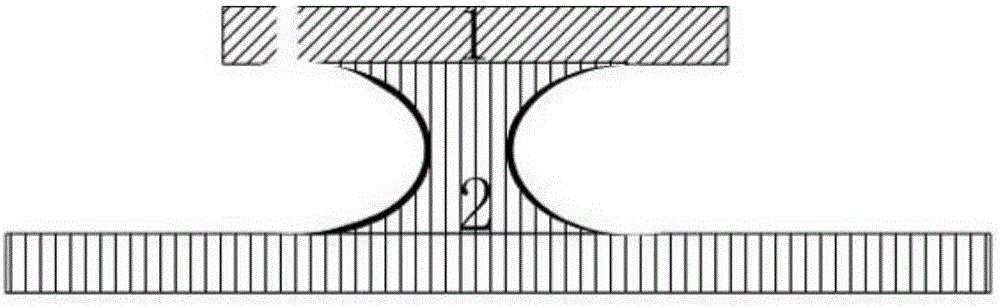

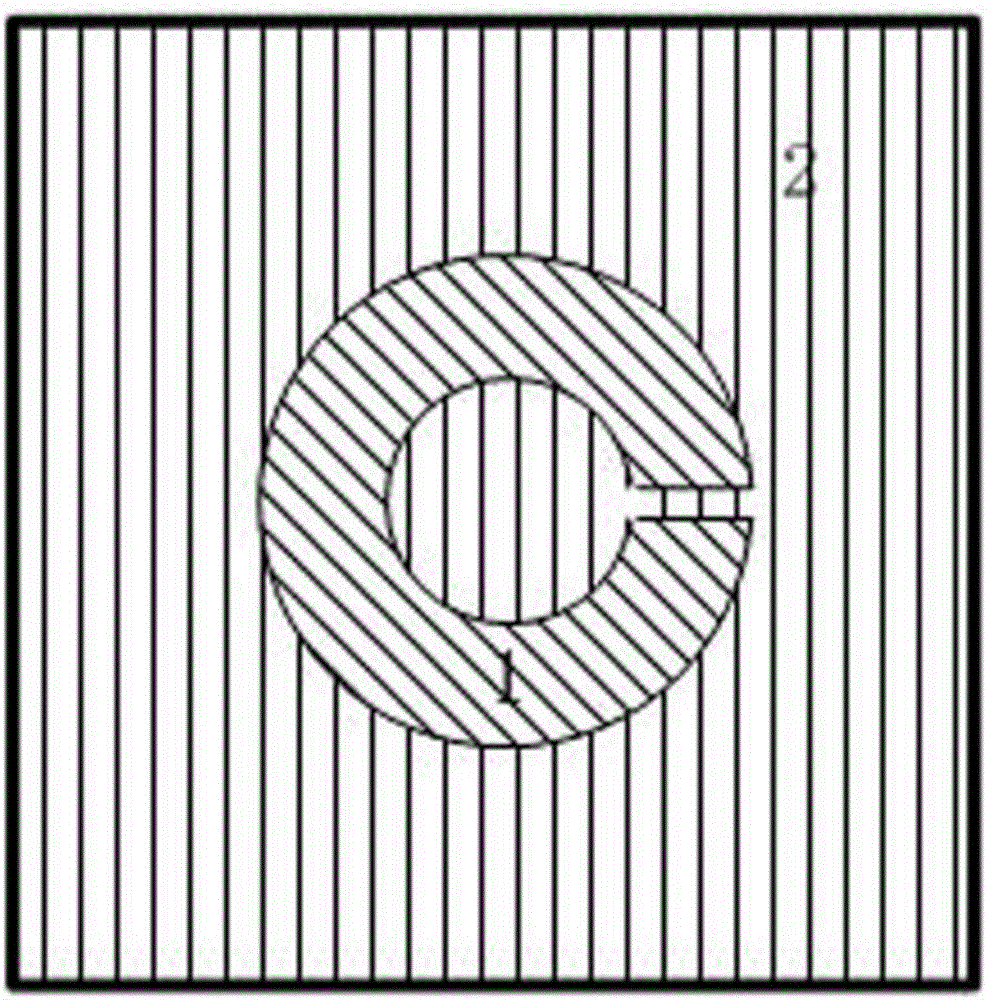

[0023] Taking the preparation of a nitride mode-locked whispering gallery micro-laser with an outer ring diameter of 10 microns and an inner ring diameter of 6 microns as an example, the preparation process is as follows:

[0024] The first step: After the purchased commercial gallium nitride wafer on silicon substrate is ultrasonically cleaned by acetone, absolute ethanol and deionized water in sequence, it is blown dry with nitrogen, and the surface of the wafer is sprayed at a speed of 4000 rpm by using a homogenizer. Spin-coating photoresist AZ5214, the spin-coating time is 60 seconds (the thickness of the photoresist is 1.5 microns); Technology, define a notched annular film microcavity pattern structure on the spin-coated photoresist layer, and the photolithography machine model is MA6.

[0025] Step 2: Use an electron beam eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com