Preparation method and application of chitosan-shell powder compound adsorbent

A composite adsorption and shell powder technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc., can solve problems such as poor interface bonding of composites, increased use of chemical reagents, and impact on adsorption performance, etc., to achieve The effect of good economic and social benefits, low cost, and excellent adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Wash the discarded mussel shells to remove the residual meat;

[0030] 2) calcining the mussel shells from which the flesh has been removed at 150° C., and pulverizing them to obtain shell powder;

[0031] 3) mixing 1 mass part of shell powder with 20 mass parts of water and stirring to prepare a shell powder suspension;

[0032] 4) The chitosan of 1 mass part is mixed with the mass concentration of 100 mass parts of 0.1% hydrochloric acid, stirred, and prepared chitosan solution;

[0033] 5) under rapid stirring, chitosan accounts for 5% of shell powder mass, chitosan solution is slowly added dropwise in the shell powder suspension, and chitosan is separated out on the surface of shell powder;

[0034] 6) Filter with a sieve, rinse the filtrate with water, and wash away the calcium salt generated by the reaction;

[0035] 7) The filtrate after washing with water is dried at 40° C. and ground to obtain a chitosan-shell powder composite adsorbent.

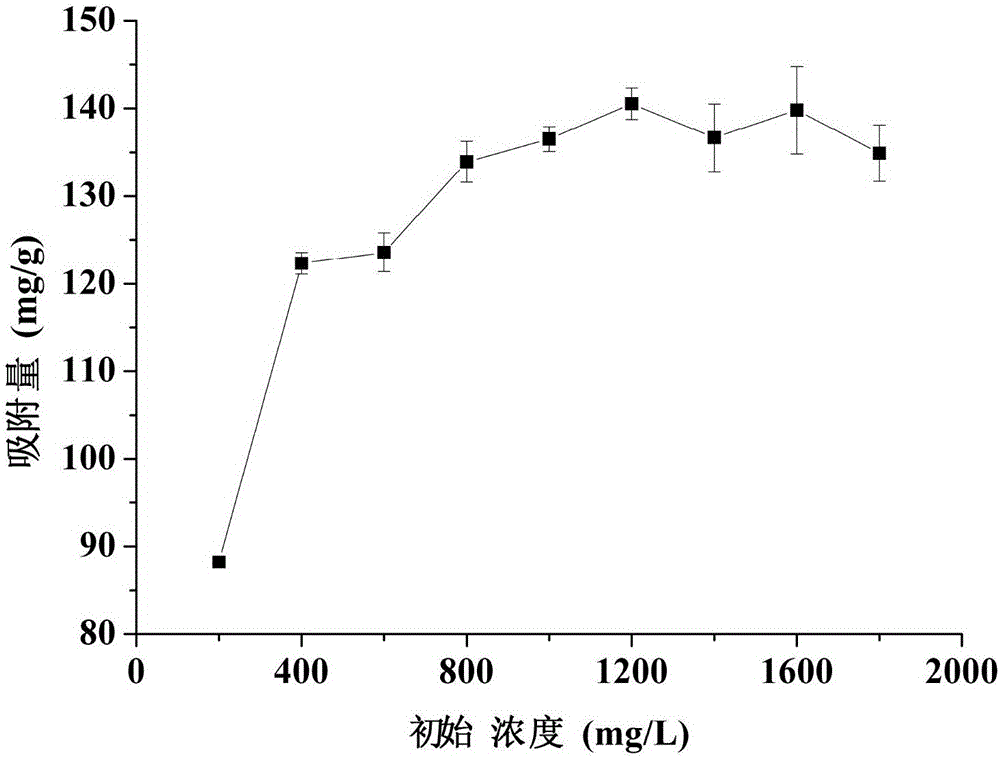

[0036] from fi...

Embodiment 2

[0038] 1) Washing the discarded scallop shells to remove residual meat;

[0039] 2) calcining the scallop shells from which the flesh has been removed at 400° C., and pulverizing them to obtain shell powder;

[0040] 3) mixing 1 mass part of shell powder with 100 mass parts of water and stirring to prepare shell powder suspension;

[0041] 4) the chitosan of 5 mass parts is mixed with the mass concentration of 100 mass parts of 10% citric acid, stirred, and prepared chitosan solution;

[0042] 5) under rapid stirring, according to chitosan accounts for 10% of shell powder mass, chitosan solution is slowly added dropwise in the shell powder suspension, and chitosan is separated out on the surface of shell powder;

[0043] 6) Filter with a sieve, rinse the filtrate with water, and wash away the calcium salt generated by the reaction;

[0044] 7) The filtrate after washing with water is dried at 100° C. and ground to obtain a chitosan-shell powder composite adsorbent.

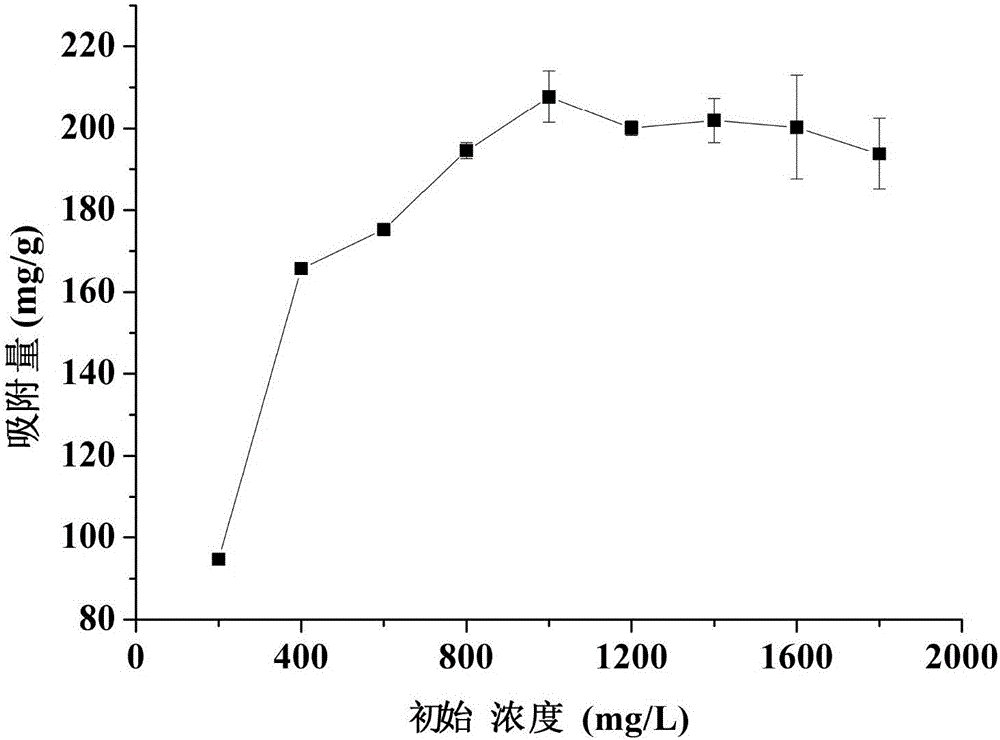

[0045]...

Embodiment 3

[0047] 1) Wash the discarded oyster shells to remove the residual meat;

[0048] 2) calcining the oyster shells from which the flesh has been removed at 380° C., and pulverizing them to obtain shell powder;

[0049] 3) mixing 1 mass part of shell powder with 60 mass parts of water and stirring to prepare shell powder suspension;

[0050] 4) 2 mass parts of chitosan and 100 mass parts of oxalic acid with a mass concentration of 5% are mixed and stirred to prepare a chitosan solution;

[0051] 5) under rapid stirring, chitosan accounts for 15% of shell powder mass, chitosan solution is slowly added dropwise in the shell powder suspension, and chitosan is separated out on the surface of shell powder;

[0052] 6) Filter with a sieve, rinse the filtrate with water, and wash away the calcium salt generated by the reaction;

[0053] 7) The filtrate after washing with water is dried at 70° C. and ground to obtain a chitosan-shell powder composite adsorbent.

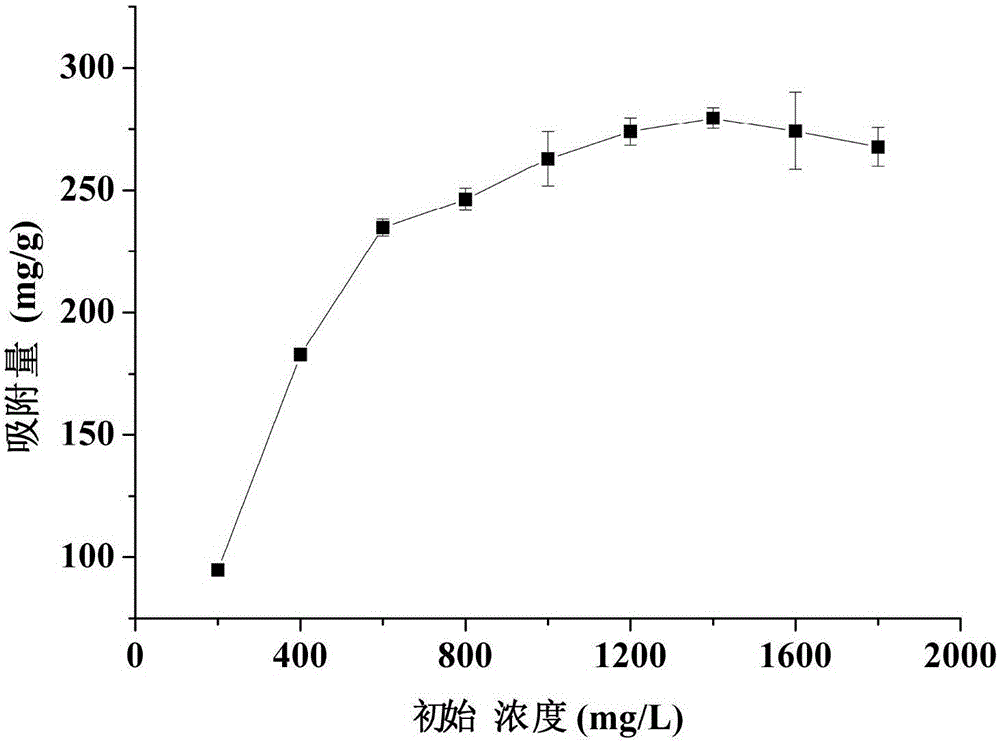

[0054] from image 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

| Saturated adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com