Rare earth-based SCR catalyst for diesel oil vehicle and preparation method of rare earth-based SCR catalyst

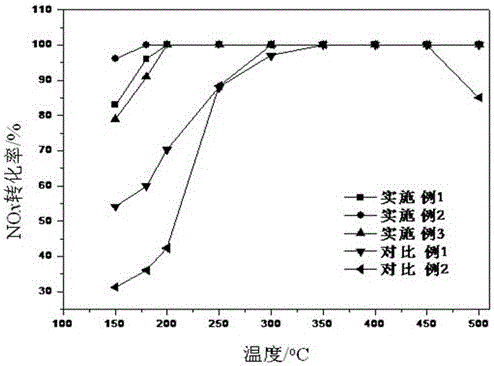

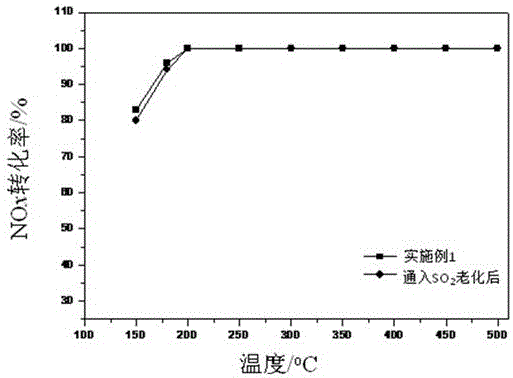

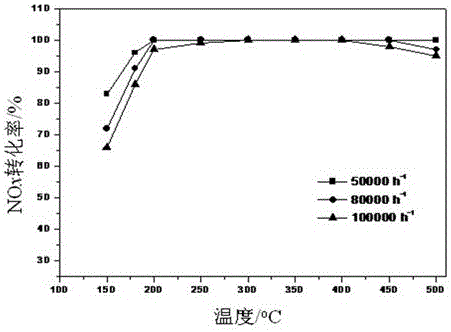

A kind of SCR catalyst, rare earth-based technology, applied in the field of rare earth-based SCR catalyst and preparation for diesel vehicles, can solve the problem of low conversion rate, achieve good low temperature performance, superior resistance to sulfur poisoning, and wide operating temperature window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a rare earth-based SCR catalyst for diesel vehicles with good low-temperature performance and a wide operating temperature window. The specific synthesis steps are as follows:

[0029] (1) Slurry preparation: Weigh 48g of rare earth-based powder and add 20g of glutinous rice glue into 120mL of deionized water. For the rare earth-based powder, the cerium-niobium composite oxide contained is 10% of the total powder mass, the iron-copper composite oxide is 2% of the total powder mass, rhenium oxide is 0.28% of the total powder mass, and the rest is titanium Tungsten powder, the synthesis method is the traditional deposition precipitation method, and the precipitation agent is ammonia water.

[0030] (2) Slurry ball mill: The slurry is ground by a planetary ball mill with a speed of 400 rpm and a running time of 10 minutes. The final slurry particle size is D 50 is 721 nm.

[0031] (3) Add microcrystalline cellulose: add 0.068 g of microcrystalline ...

Embodiment 2

[0036] A method for preparing a rare earth-based SCR catalyst for diesel vehicles with good low-temperature performance and a wide operating temperature window. The specific synthesis steps are as follows:

[0037] (1) Slurry preparation: Weigh 48g of rare earth-based powder and add 24g of glutinous rice glue into 120mL of deionized water. For the rare earth-based powder, the cerium-lanthanum composite oxide contained is 13% of the total powder mass, the manganese-samarium composite oxide is 2.5% of the total powder mass, the rhenium oxide is 0.28% of the total powder mass, and the rest is titanium Tungsten powder, the synthesis method is the traditional deposition precipitation method, and the precipitation agent is ammonia water.

[0038] (2) Slurry ball mill: The slurry is ground by a planetary ball mill with a speed of 400 rpm and a running time of 10 minutes. The final slurry particle size is D 50 is 615 nm.

[0039] (3) Add microcrystalline cellulose: add 0.180 g of mi...

Embodiment 3

[0044] A method for preparing a rare earth-based SCR catalyst for diesel vehicles with good low-temperature performance and a wide operating temperature window. The specific synthesis steps are as follows:

[0045] (1) Slurry preparation: Weigh 48g of rare earth-based powder and add 28g of glutinous rice glue into 120mL of deionized water. For the rare earth-based powder, the cerium-tin composite oxide contained is 13.5% of the total powder mass, the copper-hafnium composite oxide is 3.1% of the total powder mass, rhenium oxide is 0.35% of the total powder mass, and the rest is titanium Tungsten powder, the synthesis method is the traditional deposition precipitation method, and the precipitation agent is ammonia water.

[0046] (2) Slurry ball mill: The slurry is ground by a planetary ball mill with a speed of 400 rpm and a running time of 10 minutes. The final slurry particle size is D 50 at 586 nm.

[0047] (3) Adding microcrystalline cellulose: adding 0.279 g of microcry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com