Method for adjusting distances, densities and optical properties of two-dimensional metal nano-particle arrays

A technology of metal nanoparticles and optical properties, applied in the fields of nano-optics, nanotechnology, nanotechnology, etc., can solve the problems of complex synthesis of core-shell nanoparticles, complicated etching or replacement steps, etc., to achieve low material cost and optimized energy conversion. Efficiency, simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

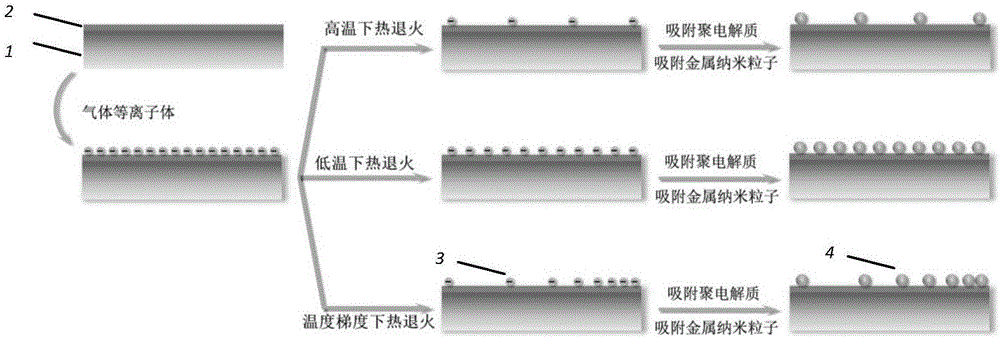

Method used

Image

Examples

Embodiment 1

[0025] 1) Cleaning and hydrophilization of the quartz substrate: place the quartz wafer in acetone and ultrasonically clean it for 5 minutes, then ultrasonically clean it with absolute ethanol for 5 minutes, and then wash it with deionized water for 5 times until no ethanol remains; Treatment solution (mass fraction is 98% concentrated sulfuric acid and mass fraction is the mixed solution of 30% hydrogen peroxide, the volume ratio of the two is 2:1) boil treatment 30min, then repeatedly wash with deionized water until no acid remains; Bake at 100°C for 30 minutes to obtain a quartz substrate with a dry, clean and hydrophilic surface;

[0026] 2) Preparation of polymer film substrate: Polystyrene solid particles were dissolved in toluene to obtain a solution with a mass fraction of 1.5%. Add 0.5mL polystyrene toluene solution dropwise on 1×1cm 2 On a quartz substrate, under the condition of 3000rpm, uniform glue for 1min, spin coating to form a film; then bake in an oven at 12...

example 1

[0031] 1) The cleaning and hydrophilization treatment methods of the quartz substrate are shown in Example 1;

[0032] 2) The preparation method of the polymer film substrate is shown in Example 1;

[0033] 3) The method for modifying the polymer film substrate with oxygen plasma is shown in Example 1;

[0034] 4) Place the polystyrene film treated in step 3) together with the quartz substrate on an electric heating plate at 100° C. for 15 minutes of thermal annealing, and then soak it in 0.5% polydiallyl di Into methyl ammonium chloride aqueous solution for 5 minutes, rinse with deionized water after taking it out, and blow dry with nitrogen;

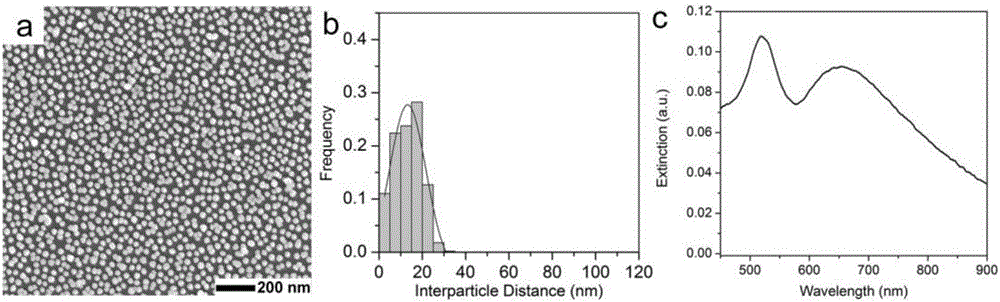

[0035] 5) Soak the substrate obtained in step 4) in an aqueous solution of 18nm gold nanospheres for adsorption for 6 hours, rinse with deionized water and absolute ethanol in turn after taking it out, and finally dry it with nitrogen, and the obtained two-dimensional gold nanospheres The density of the particle array is 547.6 partic...

Embodiment 3

[0037] 1) The cleaning and hydrophilization treatment methods of the quartz substrate are shown in Example 1;

[0038] 2) The preparation method of the polymer film substrate is shown in Example 1;

[0039] 3) The method for modifying the polymer film substrate with oxygen plasma is shown in Example 1;

[0040] 4) Place the polystyrene film treated in step 3) together with the quartz substrate on an electric heating plate at 115° C. for 15 minutes of thermal annealing, and then soak it in 0.5% polydiallyl di Into methyl ammonium chloride aqueous solution for 5 minutes, rinse with deionized water after taking it out, and blow dry with nitrogen;

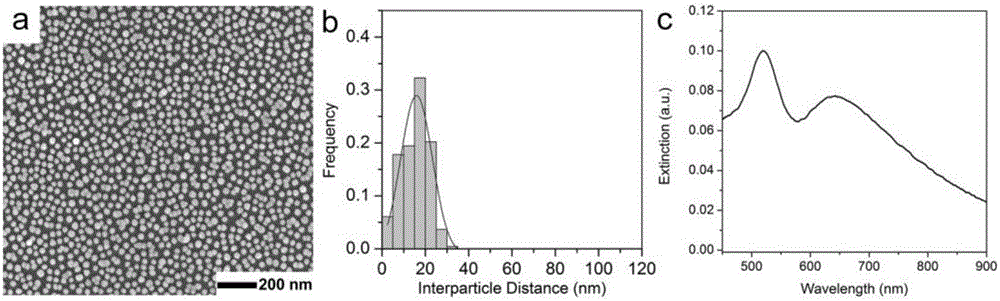

[0041] 5) Soak the substrate obtained in step 4) in an aqueous solution of 18nm gold nanospheres for adsorption for 6 hours, rinse with deionized water and absolute ethanol in turn after taking it out, and finally dry it with nitrogen, and the obtained two-dimensional gold nanospheres The density of the particle array is 529.6 partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com