Structure, synthesis and application of a spirobifluorene-based hole-transporting material

A technology of hole transport materials and spirobifluorene, which is applied in the direction of luminescent materials, preparation of organic compounds, preparation of amino hydroxyl compounds, etc., can solve the problems of high synthesis cost, harsh synthesis conditions, and difficult purification, and achieve low cost and stability Good performance and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

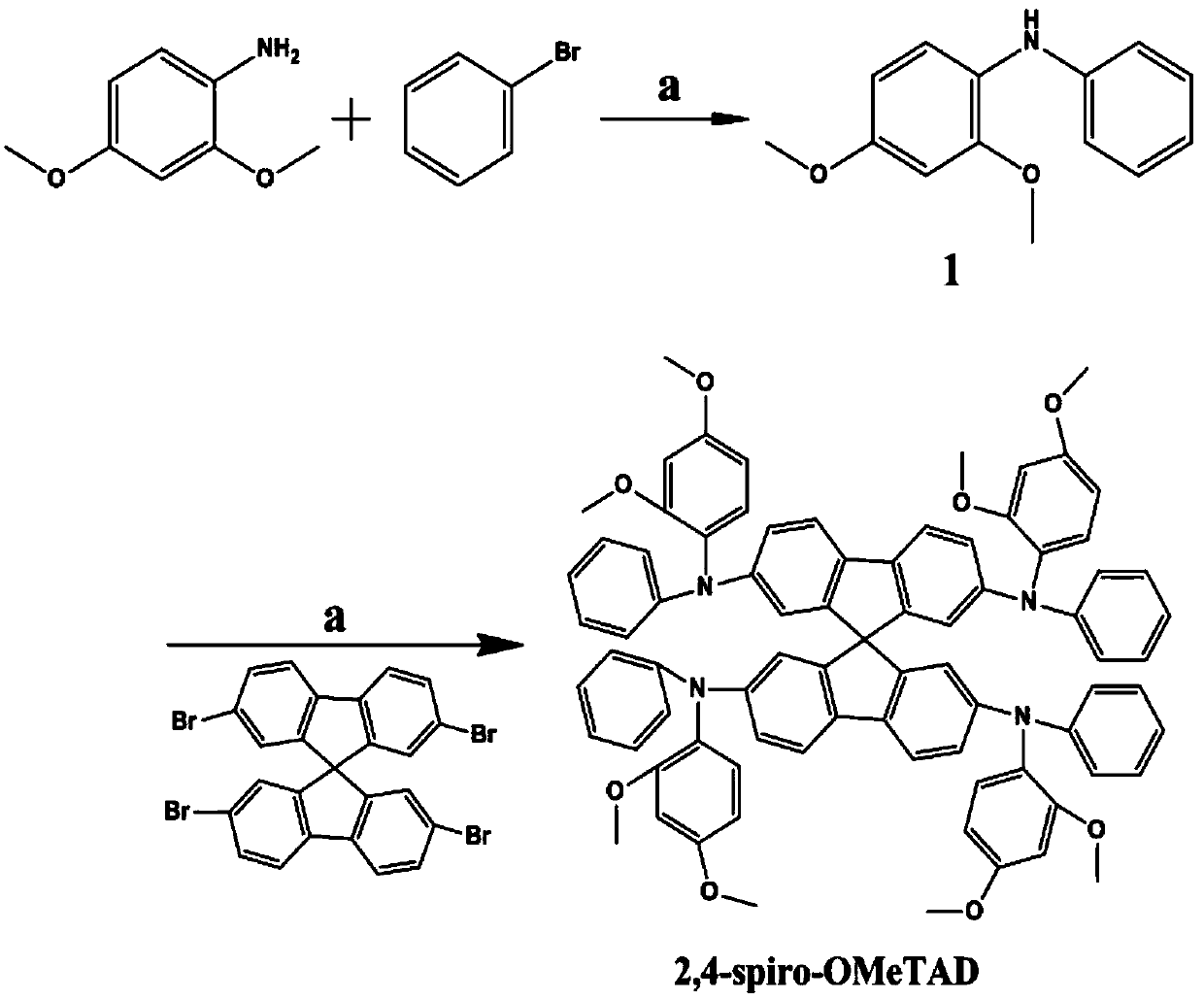

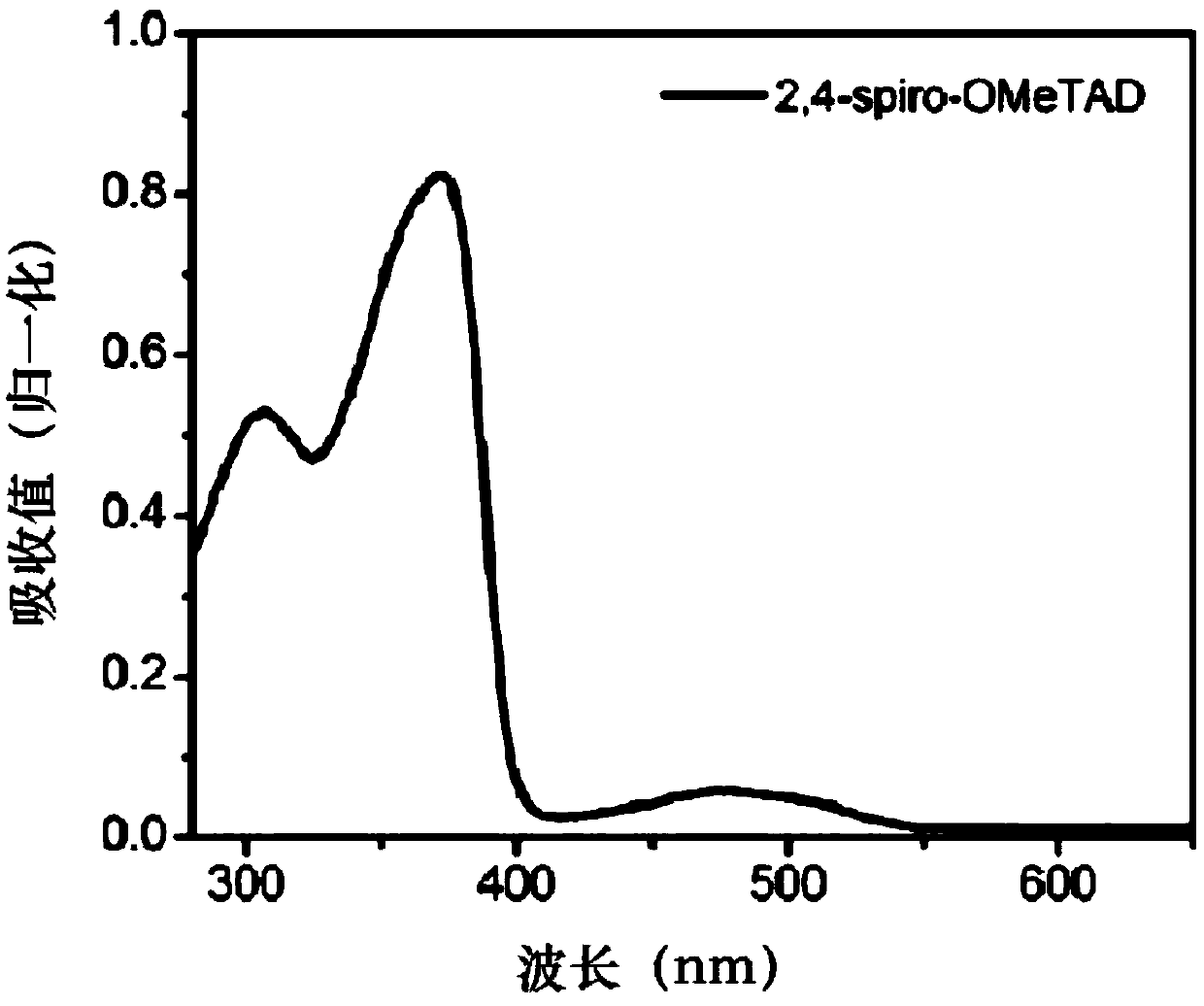

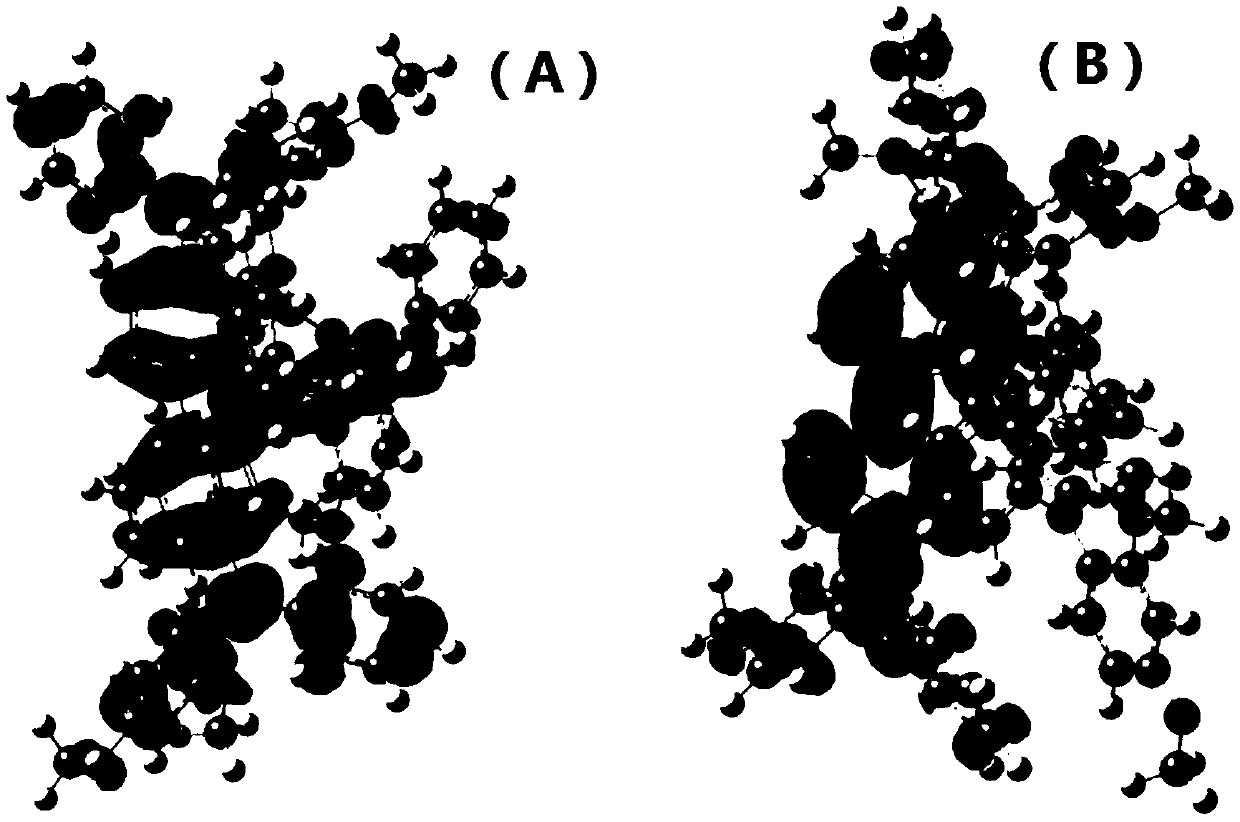

[0031] Example 1: Preparation and performance characterization of spirobifluorene hole transport material 2,4-spiro-OMeTAD

[0032] 2,4-dimethoxyaniline (1.00g, 6.54mmol), bromobenzene (0.95g, 7.19mmol), sodium tert-butoxide (0.94g, 9.80mmol), tri-tert-butylphosphine (0.021g, 0.10mmol ), tris(dibenzylideneacetone)dipalladium (0.06g, 0.07mmol), and 15ml of anhydrous toluene were heated to 110°C under the protection of argon, and the temperature was maintained and stirred for 12 hours. After cooling to room temperature, extract with ethyl acetate and brine (saturated sodium chloride solution), the organic phase was dried and concentrated to obtain a crude product, and the crude product was subjected to column chromatography (ethyl acetate:petroleum ether=1:100 ) to obtain compound 1. The hydrogen spectrum data of compound 1 is: 1 HNMR (CDCl 3 400Hz) δ=3.84(s,3H),3.87(s,3H),6.49(dd,1H,J1=4Hz,J2=4Hz),6.58(d,1H,J=4Hz),6.89(m,1H) ,7.04(m,2H),7.27(m,3H).

[0033] Compound 1 (1.0...

Embodiment 2

[0040] Example 2: Preparation and performance characterization of solar cells based on the TDT-OMeTPA hole transport material of the present invention

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com