Preparation method of high-solid content waterborne polyurethane emulsion

A technology of water-based polyurethane with high solid content, which is applied in the field of preparation of high-solid content water-based polyurethane dispersion emulsion, which can solve the problems of high reactivity between amino groups and isocyanate, difficult control of the production process, uneven chain extension, etc., to ensure controllability and repeatability, mild and controllable chain extension process, enhanced uniformity and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

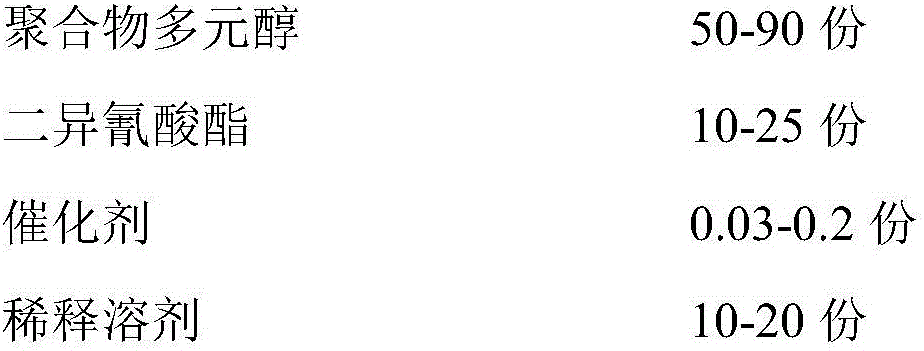

Method used

Image

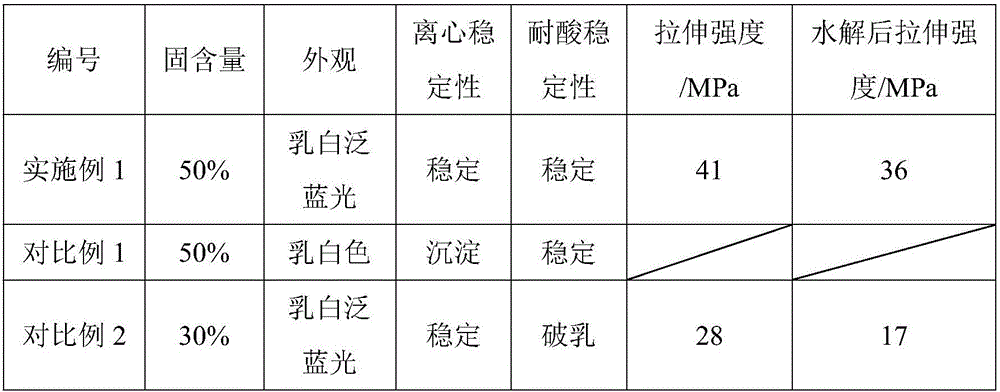

Examples

Embodiment 1

[0031] 270g of polybutylene adipate diol (PBA) with a number average molecular weight of 2000 and a hydroxyl value of 56mg KOH / g was vacuum dehydrated at 110°C for 1.5h, cooled to 60°C, and 28.9g of Isophor was added Ketone diisocyanate (IPDI), 21.9g hexyl diisocyanate (HDI), under the protection of nitrogen, heat up to 90°C, and mechanically stir for 1.5h; then cool down to 55°C, add 0.22g of dibutyltin dilaurate, dilute solvent acetone 50g, continue to react at 70°C for 1.5h; then lower the temperature to 50°C, add 75g of diluting solvent acetone, keep the temperature of the prepolymer at 45°C, and prepare the pre-configured chain extender aqueous solution (take 1.25g N-amine ethylethanolamine, 13.2 g of 50% sodium ethylenediamine sulfonate aqueous solution and 10 g of deionized water were mixed uniformly) into the reaction system dropwise within 1 min, and kept at 45° C. for 25 min. Then add 250 g of diluting solvent acetone and stir for 20 minutes, then add water for high-...

Embodiment 2

[0048] 270g of polyneopentyl adipate diol (PNA) with a number average molecular weight of 2000 and a hydroxyl value of 56mg KOH / g was vacuum dehydrated at 110°C for 1.5h, cooled to 60°C, and 38.5g of isofor ketone diisocyanate (IPDI), 14.6g hexyl diisocyanate (HDI), under the protection of nitrogen, heat up to 90 ° C, mechanically stir the reaction for 1.5 h; then cool down to 55 ° C, add dibutyltin dilaurate 0.22 g, dilution solvent Acetone 45g, continue to react at 70°C for 1.5h; then cool down to 50°C, add 70g of diluting solvent acetone, keep the temperature of the prepolymer at 45°C, mix the pre-configured small molecular amine aqueous solution (take 1.00g ethylenediamine and 8g of deionized water (mixed uniformly) was added dropwise to the reaction system within 1min, and the reaction was continued for about 10min at 45°C, followed by the dropwise addition of 13.2g of 50% sodium ethylenediaminoethanesulfonate aqueous solution with controlled dropwise Adding time is 30-90...

Embodiment 3

[0050] 135g number average molecular weight is 2000, the polyadipate neopentyl glycol ester diol (PNA) of hydroxyl value 56mgKOH / g and 135g number average molecular weight is 2000, the polyadipate of hydroxyl value 56mgKOH / g Mix hexanediol ester diol (PHA) and vacuum dehydrate at 110°C for 1.5h, cool down to 60°C, add 57.8g of isophorone diisocyanate (IPDI), and raise the temperature to 90°C under nitrogen protection, mechanically Stir the reaction for 1.5h; then cool down to 55°C, add 0.22g of stannous octoate, 52g of diluting solvent acetone, and continue the reaction at 70°C for 1.5h; then cool down to 50°C, add 75g of diluting solvent acetone, and keep the temperature of the prepolymer at At 45°C, mix the pre-configured chain extender aqueous solution (take 1.30g of N-aminoethylethanolamine, 13.0g of 50% sodium ethylenediamine ethanesulfonate aqueous solution with a mass fraction of 50%, and 10g of deionized water to mix uniformly) for 1min Add it dropwise to the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com