Sulfate corrosion resistant graphene-concrete composite material and preparation method thereof

A composite material and sulfate-resistant technology, which is applied in the field of building materials, can solve the problems of complex preparation process of modified graphene, technical research on its own structure, and low degree of dispersion, so as to achieve good sulfate corrosion resistance, cost control, and The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

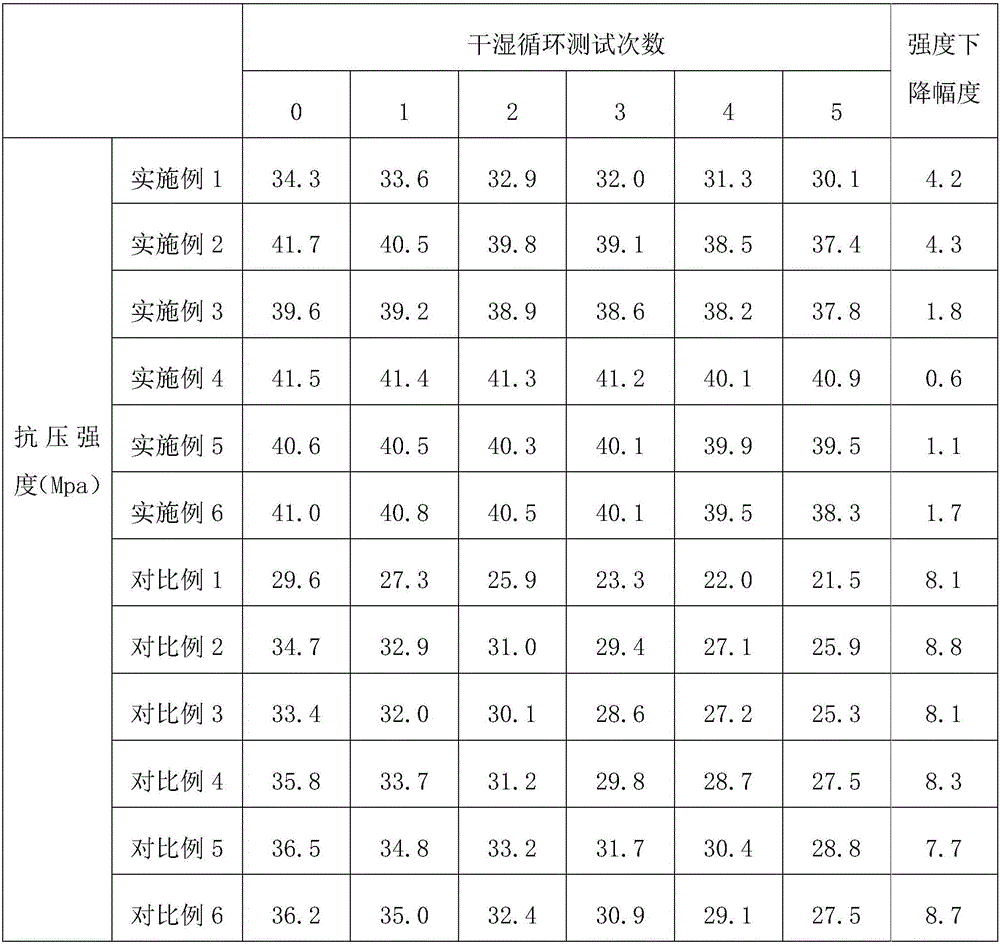

Examples

Embodiment 1

[0055] Preparation of graphene concrete resistant to sulfate attack:

[0056] 1) Weigh 500g of graphene, add it into 250L solvent prepared by water and ethanol according to the ratio of 9:1, add glacial acetic acid to adjust the pH to 6.5 while stirring, stir well, then slowly add 300gTEC6300 into the solution dropwise, Ultrasonic dispersion was performed for 40 minutes to obtain a graphene dispersion liquid, which was ready for use after completion.

[0057] 2) Weigh 45 kg of glass fiber, add it to 100 L of deionized water, adjust the pH value of the above solution to 9 with NaOH solution, and disperse it ultrasonically for 60 min. After the completion of suction filtration, the glass fiber is placed in a drying oven and dried to a constant weight at a temperature of 105°C for use.

[0058] 3) Weigh 40kg from step 2) and add it to 200L of the graphene dispersion obtained in step 1), disperse it by ultrasonic for 60 minutes, filter it with suction after completion, and then p...

Embodiment 2

[0062] Preparation of graphene concrete resistant to sulfate attack:

[0063] 1) Weigh 600g of graphene, add it to the 300L solvent prepared by water and ethanol according to the ratio of 6:1, add glacial acetic acid to adjust the pH to 6.5 while stirring, after stirring evenly, slowly add 300gTEC6300 to the solution, Ultrasonic dispersion was performed for 90 minutes to obtain a graphene dispersion liquid, which was ready for use after completion.

[0064] 2) Weigh 45 kg of glass fiber, add it to 100 L of deionized water, adjust the pH value of the above solution to 10 with NaOH solution, and disperse it ultrasonically for 60 min. After the completion of suction filtration, the glass fiber is placed in a drying oven and dried to a constant weight at a temperature of 105°C for use.

[0065] 3) Weigh 40kg from step 2) and add it to 200L of the graphene dispersion obtained in step 1), ultrasonically disperse for 90 minutes, and then filter with suction, then place the glass fib...

Embodiment 3

[0069] Preparation of graphene concrete resistant to sulfate attack:

[0070] 1) Weigh 500g of graphene, add it to 250L solvent prepared by water and ethanol according to the ratio of 9:1, add glacial acetic acid to adjust the pH to 6.5 while stirring, stir well, then slowly add 250gTEC6300 to the solution dropwise, Ultrasonic dispersion was performed for 60 minutes to obtain a graphene dispersion liquid, which was ready for use after completion.

[0071] 2) Weigh 45 kg of glass fiber, add it to 100 L of deionized water, adjust the pH value of the above solution to 9 with NaOH solution, and disperse it ultrasonically for 60 min. After the completion of suction filtration, the glass fiber is placed in a drying oven and dried to a constant weight at a temperature of 105°C for use.

[0072] 3) Weigh 40kg from step 2) and add it to 200L of the graphene dispersion obtained in step 1), ultrasonically disperse for 120min, and then filter with suction after completion, then place the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com