Preparation method for polymer composite electrolyte membrane

A composite electrolyte membrane and polymer technology, applied in the field of polymer materials, can solve the problems of poor surface uniformity, complex preparation process, and increased surface resistance of composite membranes, achieve low surface roughness, clear application prospects, and comprehensive The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0097]

[0098] (1) Raw materials

[0099] Polymer electrolyte A solution: Nafion solution F1;

[0100] Polymer electrolyte B solution: Nafion solution F2;

[0101] Porous membrane: expanded polytetrafluoroethylene porous membrane PM1.

[0102] (2) Preparation of porous membrane containing polymer electrolyte A solution

[0103] After fixing the porous membrane with an outer frame, the polymer electrolyte A solution was used to coat the two surfaces respectively three times to obtain a porous membrane containing the polymer electrolyte A solution. The content of the polymer electrolyte A solution in the porous membrane was 60% of the saturated liquid absorption capacity of the porous membrane.

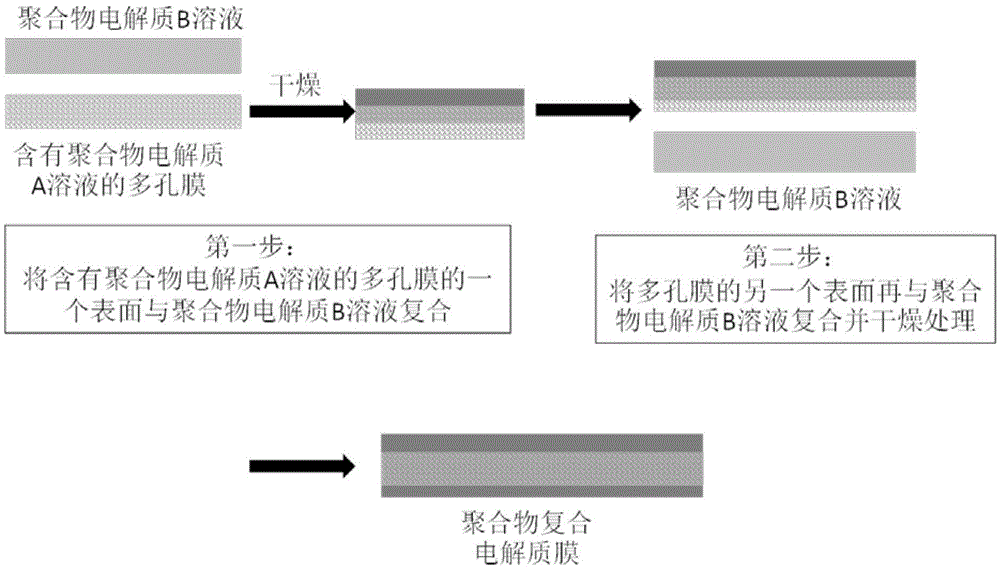

[0104] (3) Composite

[0105] On one surface of the fixed porous membrane containing the polymer electrolyte A solution obtained in step (2), cast the polymer electrolyte B solution and dry it in a vacuum oven at 60°C (vacuum degree 100Pa), and then dry it in another The polymer...

Embodiment 2

[0112]

[0113] (1) Raw material

[0114] Polymer electrolyte A solution: sulfonated polyetheretherketone SPEEK1 / N-methylpyrrolidone solution, the viscosity at 25°C is 50 centipoise;

[0115] Polymer electrolyte B solution: sulfonated polyetheretherketone SPEEK1 / N-methylpyrrolidone solution, the viscosity at 25°C is 1000 centipoise;

[0116] Porous membrane: expanded polytetrafluoroethylene porous membrane PM2.

[0117] (2) Preparation of porous membrane containing polymer electrolyte A solution

[0118] Submerge the porous membrane into the polymer electrolyte A solution, take it out after standing for 10 minutes, and fix it with an outer frame to obtain a porous membrane containing the polymer electrolyte A solution. The content of the polymer electrolyte A solution in the porous membrane is 100% of the saturated liquid absorption capacity of the porous membrane.

[0119] (3) Composite:

[0120] First, use a scraper with a thickness of 100 microns to scrape and coat th...

Embodiment 3

[0127]

[0128] (1) Raw material

[0129] Polymer electrolyte A solution: sulfonated polyetheretherketone SPEEK2 / N-methylpyrrolidone solution, the viscosity at 25°C is 99 centipoise;

[0130] Polymer electrolyte B solution: sulfonated polyetheretherketone SPEEK3 / N-methylpyrrolidone solution, the viscosity at 25°C is 8000 centipoise;

[0131] Porous membrane: expanded polytetrafluoroethylene porous membrane PM3.

[0132] (2) Preparation of porous membrane containing polymer electrolyte A solution

[0133] The porous membrane is fixed with an outer frame, and then the polymer electrolyte A solution is dripped on the surface of the porous membrane, and after the solution is completely absorbed, a porous membrane containing the polymer electrolyte A solution is obtained. The content of the polymer electrolyte A solution in the porous membrane was 40% of the saturated liquid absorption capacity of the porous membrane.

[0134] (3) Composite:

[0135] First, use a scraper with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com