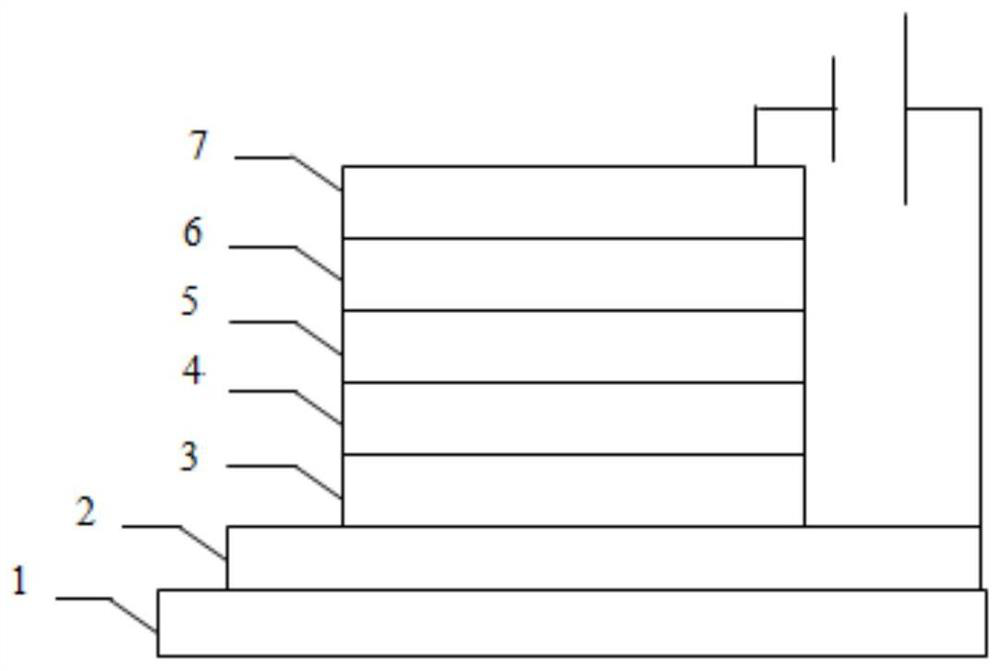

Quantum dot light-emitting diode and its preparation method

A quantum dot light-emitting and diode technology, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical components, etc. effect with width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

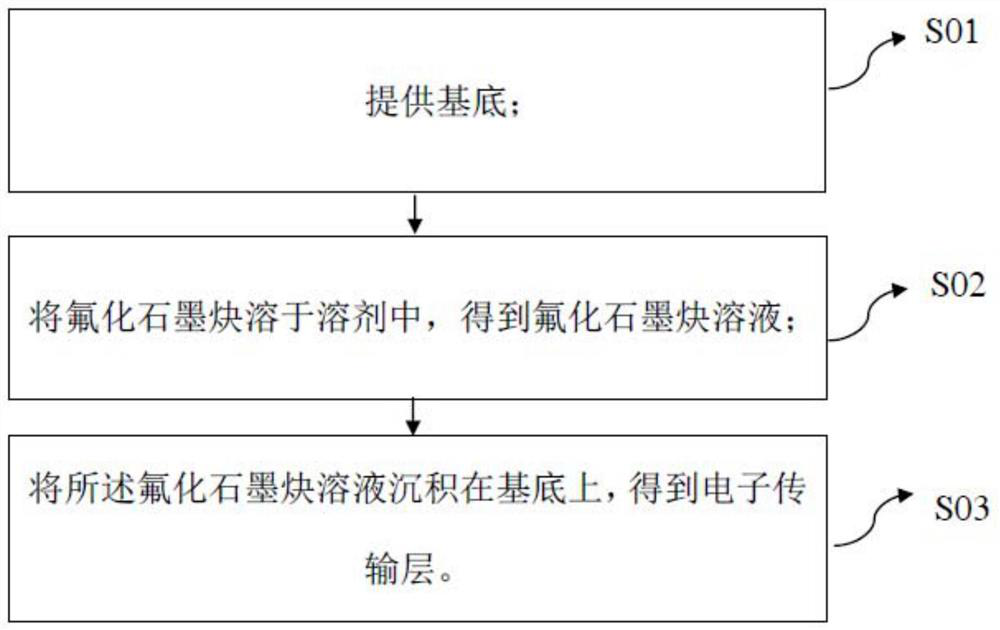

[0024] On the other hand, the embodiment of the present invention also provides a method for preparing a quantum dot light-emitting diode, such as figure 2 shown, including the following steps:

[0025] S01: Provide a base;

[0026] S02: dissolving graphyne fluoride in a solvent to obtain a graphyne fluoride solution;

[0027] S03: Depositing the graphyne fluoride solution on a substrate to obtain an electron transport layer.

[0028] The preparation method of the quantum dot light-emitting diode provided by the embodiment of the present invention uses the solution method to make the fluorinated graphyne into the electron transport layer, which not only has a simple process and low cost, but also improves the electron transport efficiency and can be matched with the quantum dot light-emitting layer The high density finally improves the light-emitting performance of the device.

[0029] Further, in the above step S01: if the surface of the substrate is a cathode (cathode su...

Embodiment 1

[0042] To use graphyne nanospheres, 1% fluorine F 2 (99% argon) etc. as an example for detailed introduction:

[0043] 1) Spread 500mg of graphdiyne powder on a watch glass, put it into a muffle furnace and continuously feed argon;

[0044] 2) After raising the temperature of the muffle furnace to 70 degrees Celsius, switch the argon gas to 1% fluorine gas (99% argon gas), cut off the fluorine gas source after 30 minutes, and cool down to room temperature after 30 minutes of heat preservation;

[0045] 3) Disperse the fluorinated graphyne in a solvent to prepare the QLED electron transport layer, and then form a QLED device with other functional layers.

Embodiment 2

[0047] To use graphyne nanospheres, 1% SF 6 (99% argon) etc. as an example for detailed introduction:

[0048] 1) Spread 500mg of graphdiyne powder on a watch glass, put it into a muffle furnace and continuously feed argon;

[0049] 2) After raising the temperature of the muffle furnace to 200 degrees Celsius, switch the argon gas to 1% SF 6 (99% argon), cut off SF after 30 minutes 6 Air source, keep warm for 30 minutes and then drop to room temperature;

[0050] 3) Disperse the fluorinated graphyne in a solvent to prepare the QLED electron transport layer, and then form a QLED device with other functional layers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com