Ensiling additive for alfalfa ensiling and application thereof

A kind of silage additive, alfalfa technology, applied in the direction of application, animal feed raw material preservation method, animal feed, etc., can solve the problems of mildew and deterioration, reduce the quality of silage, etc., and achieve the goal of reducing pH value, improving digestibility and increasing the ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Materials and methods:

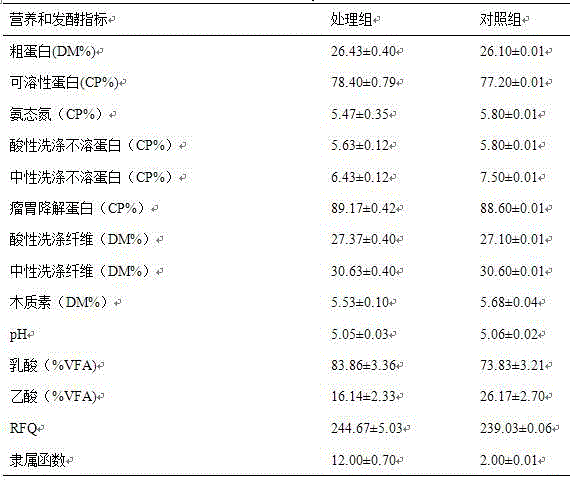

[0031] Mow the alfalfa with a forage harvester, dry it in the open air until the water content is about 65%, chop the alfalfa to 2-5cm with a guillotine, prepare silage bags with a size of 26cm×35cm, and make silage with 0.5kg of alfalfa per bag , doses I, II, and III were 1.5ml, 3ml, and 6ml of refined wood vinegar (3L, 6L, and 12L / t), and the control group added an equal amount of distilled water to replace the silage additive. Each treatment was repeated 3 times, and the added The mixture was mixed with alfalfa and placed in a silage bag, which was vacuum-sealed. After 45 days, the nutrition and silage fermentation quality indicators of the alfalfa silage samples were measured by a near-infrared analyzer. The data results are expressed as "mean ± standard deviation", and the nutritional and fermentation indicators are comprehensively evaluated by the membership function method.

[0032] result:

[0033] It can be seen from Table 2 that the ...

Embodiment 2

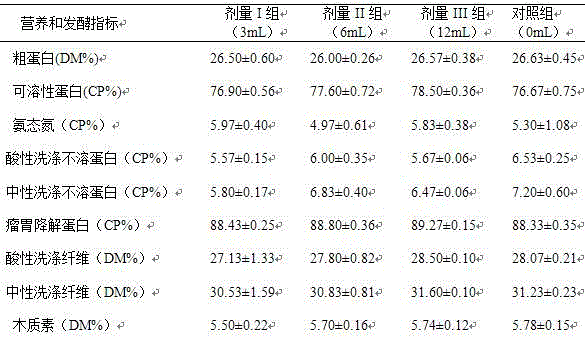

[0041] Materials and methods:

[0042] Select different varieties of alfalfa under different management methods in different plots, and record them as alfalfa group I and alfalfa group II. The alfalfa is mowed by a forage harvester. Crush to 2-5cm, prepare silage bags of 26cm×35cm size, make silage according to 0.5kg alfalfa per bag, use 3ml refined wood vinegar (6L / t) for the treatment group, add 3mL distilled water to replace the silage additive for the control group, each Three replicates were processed, the additives were mixed with alfalfa and placed in silage bags, vacuum-sealed, and after 45 days, the nutrition and silage fermentation quality indicators of alfalfa silage samples were measured by near-infrared analyzer. The data results are expressed as "mean ± standard deviation", and the nutritional and fermentation indicators are comprehensively evaluated by the membership function method.

[0043] result:

[0044] It can be seen from the nutritional and fermentatio...

Embodiment 3

[0052] Materials and methods:

[0053] Refined wood vinegar is commercially available purified bamboo vinegar.

[0054] How to use: The special machinery for alfalfa silage cuts alfalfa at the early flowering stage, chops the alfalfa to 5cm, sprays the refined wood vinegar evenly on the surface of the alfalfa at a dose of 9L / t, puts in the cellar, compacts and seals it, and opens the cellar after 60 days use.

[0055] Sample collection: After the cellar is opened, the silage sample is collected with the 9-point sampling method. The upper material layer is removed by 50 cm, and a quadrilateral is made at a distance of 30 cm from the two walls of the silo cellar and the bottom of the silo cellar, and then the midpoints of each side are connected, and each line intersects Sampling was carried out with each point as the center, and 20cm*20cm*20cm feed blocks were cut with a sterilized sharp knife, and packed in ziplock bags.

[0056] The nutrition and silage fermentation quality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com