Preparation method of environment-friendly superhydrophilic dental implant activated surface

An implant and environment-friendly technology, applied in prosthesis, medical science, tissue regeneration, etc., can solve the problems of poor surface hydrophilicity, complicated treatment process, complicated operation process, etc. Simple, bioactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] S1. Under normal temperature and pressure conditions, a 20wt% phytic acid solution is prepared in a saturated calcium hydroxide solution;

[0027] S2. Immerse the SLA-treated dental implant surface completely in the configured mixed solution, the soaking temperature is 30℃, and the soaking time is 120min;

[0028] S3. The dental implant treated with the phytic acid solution is ultrasonically cleaned with deionized water, acetone, absolute ethanol, and deionized water for 15 minutes, and then naturally dried.

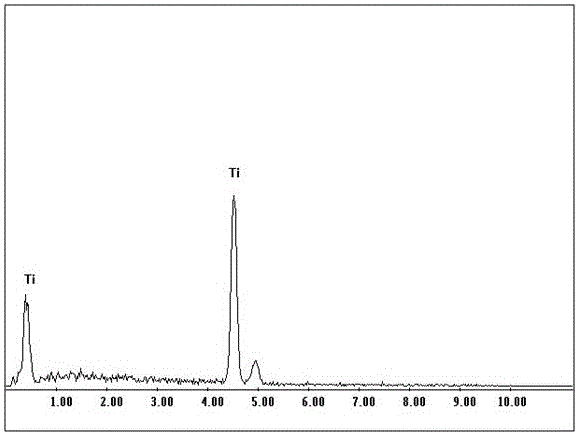

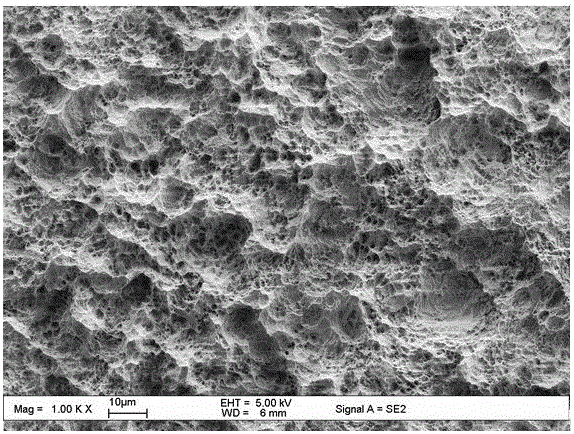

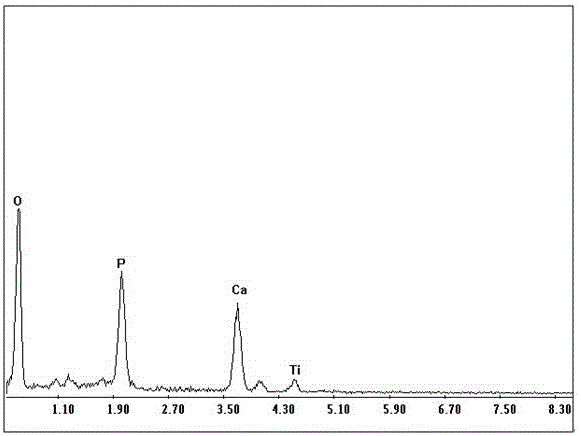

[0029] Surface element analysis: Use EDS (Energy Dispersive Spectroscopy) to analyze the composition of the SLA surface and the surface elements of the phytic acid / calcium hydroxide mixed solution after SLA treatment. SLA surface EDS map such as figure 1 As shown, the EDS spectrum of the surface of the SLA-soaked phytic acid / calcium hydroxide mixed solution is as follows figure 2 As shown, it is determined that Ca and P ions are introduced on the surface of the sample a...

Embodiment 2

[0033] S1. Under normal temperature and pressure conditions, a 20wt% phytic acid solution is prepared in a saturated calcium hydroxide solution;

[0034] S2. Immerse the SLA-treated dental implant surface completely in the configured phytic acid solution, the soaking temperature is 40℃, and the soaking time is 90min;

[0035] S3. The dental implant treated with the phytic acid solution is ultrasonically cleaned with deionized water, acetone, absolute ethanol, and deionized water for 15 minutes, and then naturally dried.

[0036] The operation steps of surface element analysis are the same as in Example 1. The EDS map of SLA surface is as follows figure 1 As shown, the EDS spectrum of the surface of the SLA-soaked phytic acid / calcium hydroxide mixed solution is as follows figure 2 As shown, it is determined that Ca and P ions are introduced on the surface of the sample after immersion in the phytic acid / calcium hydroxide mixed solution.

[0037] The operation steps of surface topograph...

Embodiment 3

[0040] S1. Under normal temperature and pressure conditions, a 20wt% phytic acid solution is prepared in a saturated calcium hydroxide solution;

[0041] S2. Immerse the SLA-treated dental implant surface completely in the configured phytic acid solution, the soaking temperature is 50℃, and the soaking time is 80min;

[0042] S3. The dental implant treated with the phytic acid solution is ultrasonically cleaned with deionized water, acetone, absolute ethanol, and deionized water for 15 minutes, and then naturally dried.

[0043] The operation steps of surface element analysis are the same as in Example 1. The EDS map of SLA surface is as follows figure 1 As shown, the EDS spectrum of the surface of the SLA-soaked phytic acid / calcium hydroxide mixed solution is as follows figure 2 As shown, it is determined that Ca and P ions are introduced on the surface of the sample after immersion in the phytic acid / calcium hydroxide mixed solution.

[0044] The operation steps of surface topograph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com