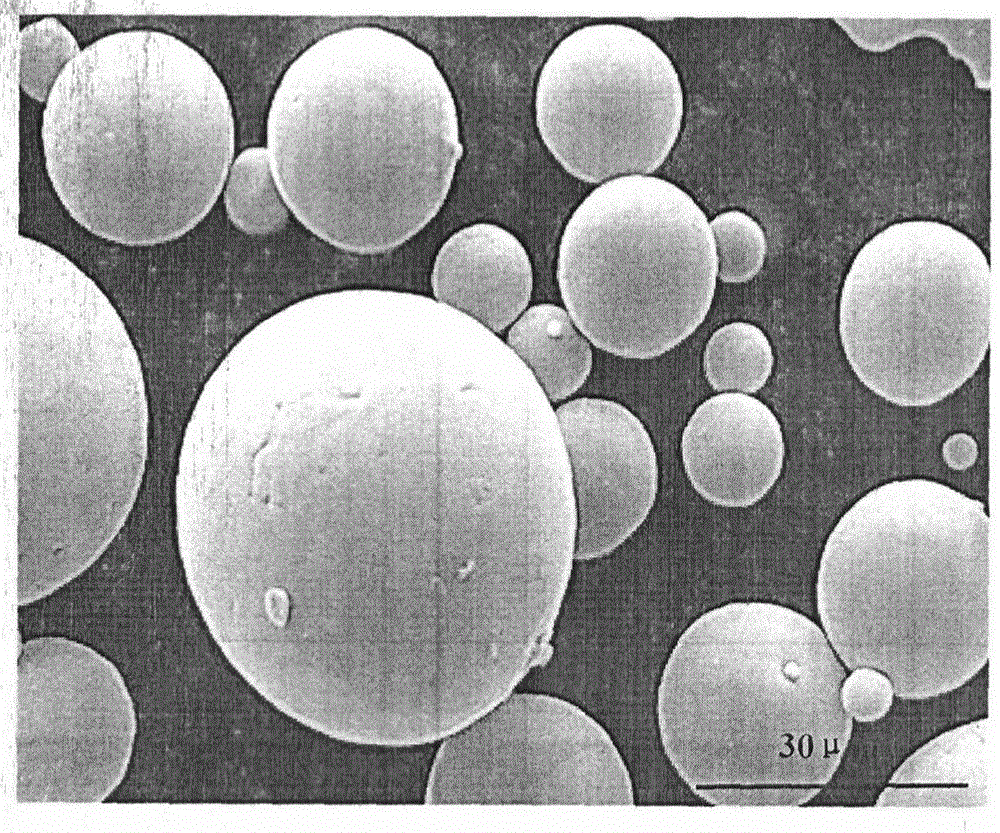

Method for rapidly synthesizing spherical aluminum nitride powder with uniform grain distribution

A technology of alumina powder and aluminum nitride, applied in the field of aluminum nitride, can solve the problems of uneven product particle size distribution, affecting the use of aluminum nitride, and expensive production costs, and achieves easy control, high production cycle, and high cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for rapidly synthesizing spherical aluminum nitride powder with uniform particle size distribution. The production steps are:

[0028] Step 1. Mix 100g of single-grade alumina powder with a particle size distribution of 13-15μm and 1g of calcium fluoride to obtain a powder with good uniformity;

[0029] Step 2. Put the mixed powder in step 1 into a multi-functional sintering furnace, inject a mixed gas of 80% carbon monoxide and 20% nitrogen, keep the temperature at 1250° C. for 3 hours, and then cool naturally to obtain an aluminum nitride block;

[0030] Step 3: Ball mill the aluminum oxide block for 18 hours to form a powder, put it into a mixed acid with a concentration of 10% hydrofluoric acid and 10% nitric acid for 1 hour, wash it with water, and finally dry it at 110±3°C for 1.5 hours. Aluminum nitride powder was obtained.

Embodiment 2

[0032] A method for rapidly synthesizing spherical mendefurium nitride powder with uniform particle size distribution. The production steps are:

[0033] Step 1. Mix 100g of single-graded alumina powder with a particle size distribution of 7-9μm and 2g of calcium fluoride to obtain a powder with good uniformity;

[0034] Step 2. Put the mixed powder in step 1 into a multi-functional sintering furnace, introduce a mixed gas of 80% carbon monoxide and 20% nitrogen, keep it warm at 1250°C for 3 hours, and then cool naturally to obtain an aluminum nitride block

[0035] Step 3: Ball mill the aluminum oxide block for 18 hours to form a powder, put it into a mixed acid with a concentration of 15% hydrofluoric acid and 15% nitric acid for 1 hour, wash it with water, and finally dry it at 110±3°C for 1.5 hours. Aluminum nitride powder was obtained.

Embodiment 3

[0037] A method for rapidly synthesizing spherical aluminum nitride powder with uniform particle size distribution. The production steps are:

[0038] Step 1. Mix 100g of single-grade alumina powder with a particle size distribution of 3-5μm and 3g of calcium fluoride to obtain a powder with good uniformity;

[0039] Step 2. Put the mixed powder in step 1 into a multi-functional sintering furnace, inject a mixed gas of 80% carbon monoxide and 20% nitrogen, keep it warm at 1250° C. for 5 hours, and then cool naturally to obtain an aluminum nitride block;

[0040] Step 3: ball mill the aluminum oxide block for 18 hours to form a powder, put it into a mixed acid with a concentration of 15% hydrofluoric acid and 10% nitric acid for treatment for 1 hour, wash it with clean water, and finally dry it at 110±3°C for 2 hours to obtain Aluminum nitride powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com