Hybrid nanoparticle with pH and magnetic responsiveness and preparation method thereof and application of hybride nanoparticle in nano oil-water separation emulsion

A technology of hybrid nano-particles and magnetic responsiveness, which is applied in chemical instruments and methods, water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of insufficient oil absorption capacity and washing of reduced and recovered materials, and achieve high The effect of oil absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

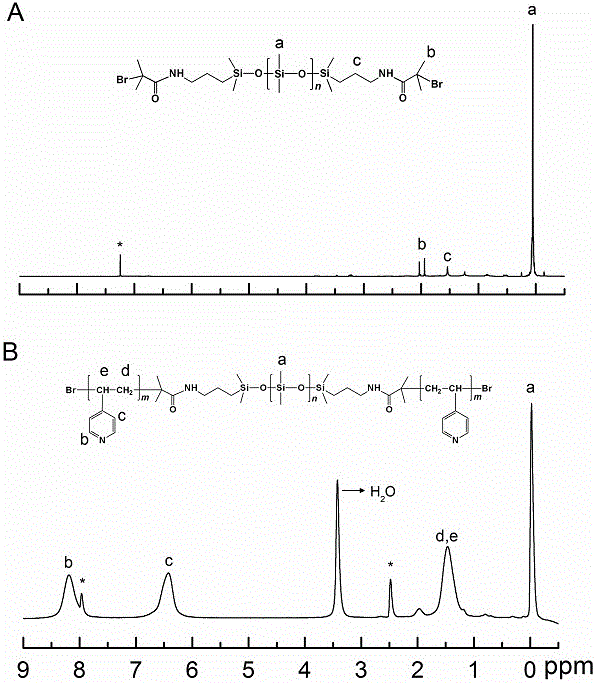

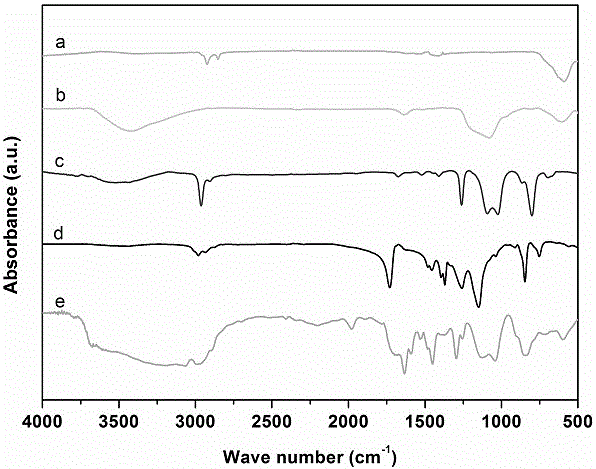

[0036] with anhydrous CH 2 Cl 2 As a solvent, use 2-bromoisobutyryl bromide to esterify the amino terminal group of PDMS, use triethylamine as an acid binding agent, stir the reactant at room temperature for 24 h, then wash the resulting solution with aqueous sodium bicarbonate for 3 times, the organic layer was separated and washed with anhydrous MgSO 4 Dry, filter after 4h, and vacuum-dry the product at 40°C to obtain the ATRP macroinitiator PDMS-diBr; add 0.56g PDMS-diBr, 72.8mg PMDETA and 2.28g 4-VP into the Schlenk reaction tube, and seal it with a rubber stopper, The oxygen in the reaction tube was removed by freeze-thaw-degassing and nitrogen filling-exhausting method. After repeated 3 times, 57.6mg CuBr and 5.0mL degassed ethanol / THF solution with a volume ratio of 1:1 were added to Into the reaction tube, polymerize at 75°C for 24h under stirring conditions, terminate the reaction by diluting the reaction mixture with THF and open it to the atmosphere, pass the reac...

Embodiment 2

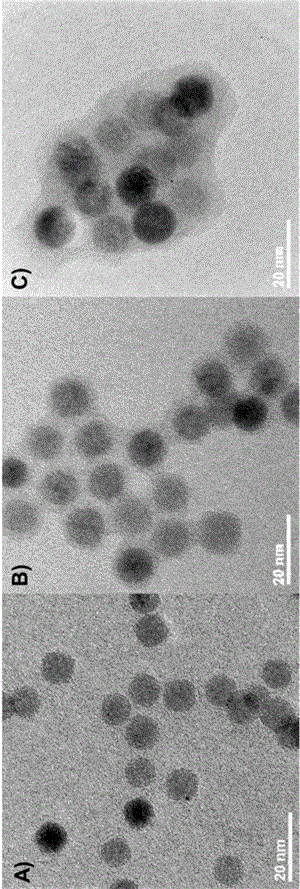

[0039]Add 2.5mmol iron(III) acetylacetonate and 20mmol oleic acid into a three-necked round-bottomed flask containing 12.8mL octadecene, heat the resulting mixture to 160°C for 30min under the protection of argon, and then heat it at 5°C / The heating rate of min was raised to 320 °C for 60 min, then the mixture was cooled to room temperature, centrifuged, and the product was washed with n-hexane / isopropanol to obtain magnetic Fe 3 o 4 Nanoparticles.

Embodiment 3

[0041] 100mg Fe dispersed in 5.0mL cyclohexane 3 o 4 The particles were added to a 12.5mL Erlenmeyer flask containing 7.5g of IPEGAL CO-520 cyclohexane, the mixture was stirred at room temperature for 60min, and 150uL of ammonia water with a mass concentration of 28% was added to form a brown microemulsion, and the stirring was continued for 60min before adding 250 μL TEOS was reacted overnight and the final product was collected by centrifugation and washed with a water / ethanol mixture to obtain Fe 3 o 4 @SiO 2 Nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com