Organic aerogel as well as preparation method and application of organic aerogel

An airgel and organic technology, applied in the field of flexible organic aerogel and its preparation, can solve the problems of low efficiency and achieve the effects of good flexibility, simple and efficient preparation process, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

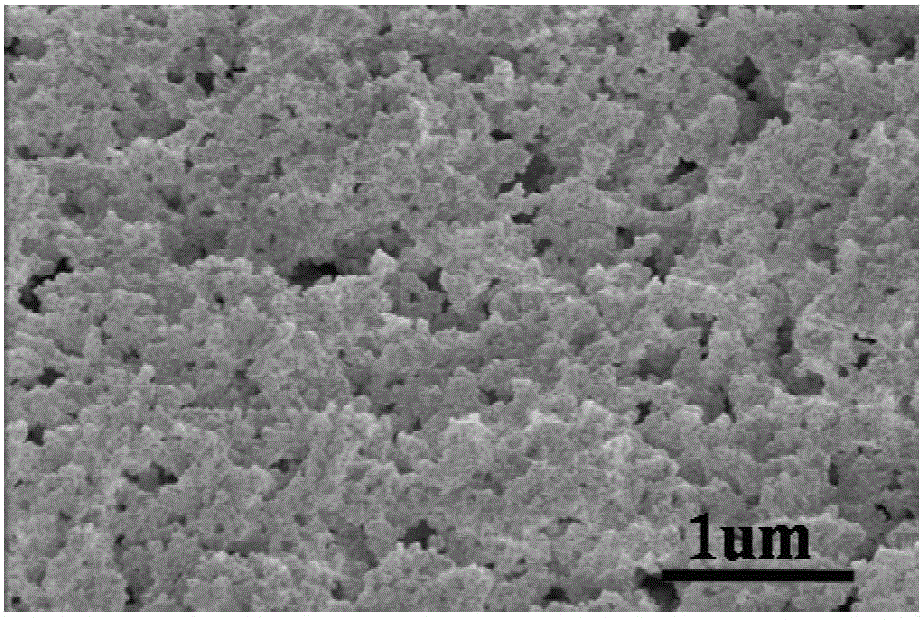

[0030] Mix 3,6-dioxo-1,8-octanedithiol and triallyl isocyanurate with a molar ratio of mercapto to vinyl of 1:0.5 in acetamide solvent, and the mass concentration of the solute is 200g / L ; Add 3% initiator azobisisobutyronitrile to the solution and stir evenly, then let it stand to obtain a gel; soak the gel in acetone at 30°C for 24h; then dry it at 80°C for 24h , to obtain flexible organic aerogels.

[0031] The density of the flexible airgel prepared in Example 1 is 0.25g cm -3 , the pore size distribution is 2-50nm, and the BET specific surface area is 800m 2 g -1 , the thermal conductivity is 0.04W·m -1 k -1 , the light transmittance is 89.5%, it can be compressed to 65% of its own volume, the bending angle reaches 150°, the compressive modulus is 1.5MPa, and the bending modulus is 0.5MPa; its appearance schematic diagram is as follows figure 1 As shown, the letters on the paper can be clearly seen from the figure, so it can be concluded that the airgel has good ligh...

Embodiment 2

[0033] Mix toluene-3,4-dithiol and trimethylolpropane triacrylate with mercapto and vinyl molar ratio of 1:1 in formamide solvent, the mass concentration of solute is 50g / L; add in the solution After stirring evenly with 0.5% initiator cumene hydrogen peroxide, the gel was obtained by standing still; the gel was soaked and aged in acetone at 50° C. for 12 hours; then vacuum freeze-dried for 24 hours to obtain a flexible organic airgel.

[0034] The density of the flexible airgel prepared in Example 2 is 0.08g cm -3, the pore size distribution is 2-250nm, and the BET specific surface area is 400m 2 g -1 , the thermal conductivity is 0.02W·m -1 k -1 , the light transmittance is 0%, it can be compressed to 70% of its own volume, the bending angle reaches 180°, the compressive modulus is 0.7MPa, and the bending modulus is 0.1MPa.

Embodiment 3

[0036] Mix pentaerythritol tetramercaptopropionate and triallyl isocyanurate with a molar ratio of mercapto and vinyl groups of 1:1 in a methanol solvent with a solute mass concentration of 10 g / L; heat the solution to 70°C for 10 hours Initiate polymerization to obtain a gel; soak and age the gel in isopropanol at 50°C for 24 hours; then supercritical CO 2 After drying for 24 hours, a flexible organic airgel was obtained.

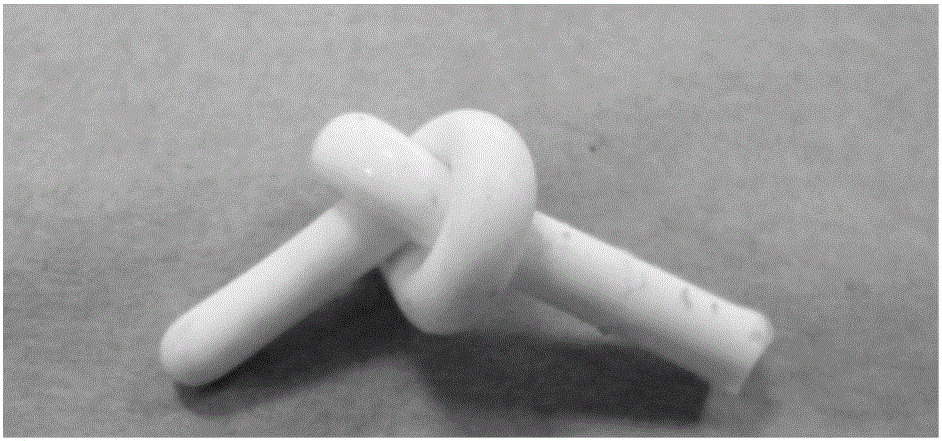

[0037] The density of the flexible airgel prepared in Example 3 is 0.05g cm -3 , the pore size distribution is 2-50nm, and the BET specific surface area is 1000m 2 g -1 , with a thermal conductivity of 0.01W·m -1 k -1 , the light transmittance is 99.9%, it can be compressed to 80% of its own volume, the bending angle reaches 180°, the compressive modulus is 0.01MPa, and the bending modulus is 0.01MPa; its appearance schematic diagram is as follows figure 2 As shown, it can be seen from the figure that the aerogel can be knotted, indicating that the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com