De-molding material capable of replacing paper skin in artificial stone manufacturing process and preparation method of de-molding material

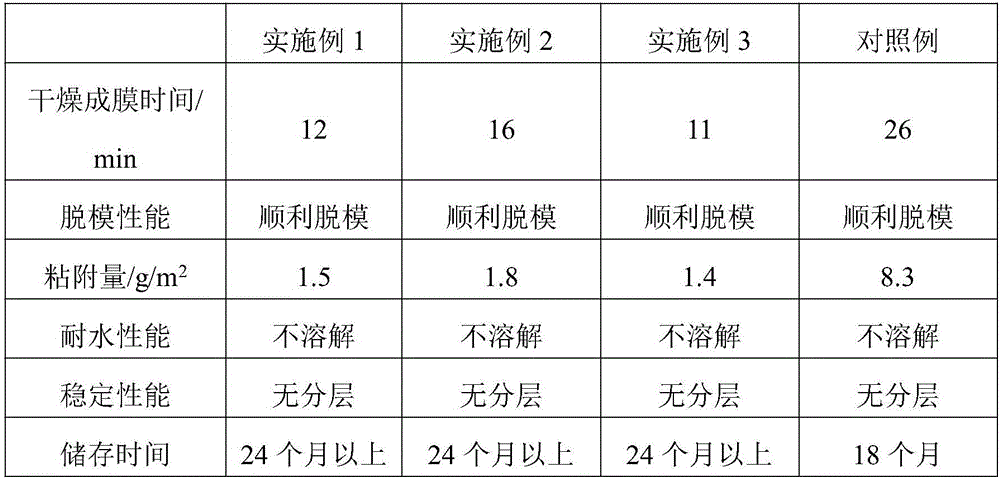

A manufacturing process and release material technology, applied in the direction of coating, etc., can solve the problems of large adhesion, high preparation cost, and long film-forming time, and achieve small adhesion, low preparation cost, and short drying and film-forming time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the demoulding material that replaces paper skin in the described artificial stone manufacturing process, comprises the following steps:

[0038] S1: Add polyvinyl alcohol and 700-1000 ℃ water into the reaction kettle, stir and raise the temperature to 82-84°C to completely dissolve the polyvinyl alcohol, and prepare mixture A;

[0039] S2: Add paraffin, sodium bicarbonate, monoammonium phosphate, initiator, regulator, surfactant, compatibilizer, dispersant, 300-500 parts of water to the mixture A prepared in step S1, and microwave power is 140 -200W, the temperature is 78-82°C, and the rotation speed is 300-500r / min, stirring for 0.6-1.2h to prepare the mixture B;

[0040] S3: Add activated clay, talcum powder, hydrosol aluminum hydroxide, accelerator, light stabilizer, and anti-aging agent to the mixture B prepared in step S2, at a microwave power of 100-130W and a temperature of 55-58°C, Stirring for 0.3-0.5h at a rotating speed of 200-400r...

Embodiment 1

[0043] A release material for replacing paper skin in the artificial stone manufacturing process, which includes the following raw materials in parts by weight: 152 parts of polyvinyl alcohol, 17 parts of paraffin, 8 parts of sodium bicarbonate, 10 parts of activated clay, and 8 parts of talcum powder , 35 parts of aluminum hydroxide in water sol, 8 parts of monoammonium phosphate, 3 parts of initiator, 1.6 parts of regulator, 4.8 parts of surfactant, 0.9 part of accelerator, 0.5 part of compatibilizer, 0.3 part of dispersant, light stabilizer 0.1 part, 0.5 part of anti-aging agent, 1300 parts of water;

[0044] Described initiator is tert-butyl peroxybenzoate;

[0045] The regulator is an acrylate regulator;

[0046] Described tensio-active agent is fatty alcohol polyoxyethylene ether sodium sulfate;

[0047] Described accelerator is dibutyltin dilaurate;

[0048] The compatibilizer is modified polyacrylate;

[0049] The dispersant is dispersant 5040;

[0050] The light ...

Embodiment 2

[0057] A release material for replacing paper skin in the artificial stone manufacturing process, which includes the following raw materials in parts by weight: 125 parts of polyvinyl alcohol, 12 parts of paraffin, 6 parts of sodium bicarbonate, 9 parts of activated clay, and 7 parts of talcum powder , 24 parts of aluminum hydroxide in water sol, 5 parts of monoammonium phosphate, 2 parts of initiator, 1 part of regulator, 3.5 parts of surfactant, 0.7 part of accelerator, 0.3 part of compatibilizer, 0.2 part of dispersant, light stabilizer 0.1 part, 0.3 part of anti-aging agent, 1050 parts of water.

[0058] Described initiator is tert-butyl peroxybenzoate;

[0059] The regulator is an acrylate regulator;

[0060] Described tensio-active agent is fatty alcohol polyoxyethylene ether sodium sulfate;

[0061] Described accelerator is dibutyltin dilaurate;

[0062] The compatibilizer is modified polyacrylate;

[0063] The dispersant is dispersant 5040;

[0064] The light stabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com