Method for growing alternating polarity GaN structure on Ga-polar GaN template

A technology of growing polarity and polarity, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of high cost of GaN substrate and difficult popularization of GaN structure, so as to save etching steps, crystal High quality and avoid damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

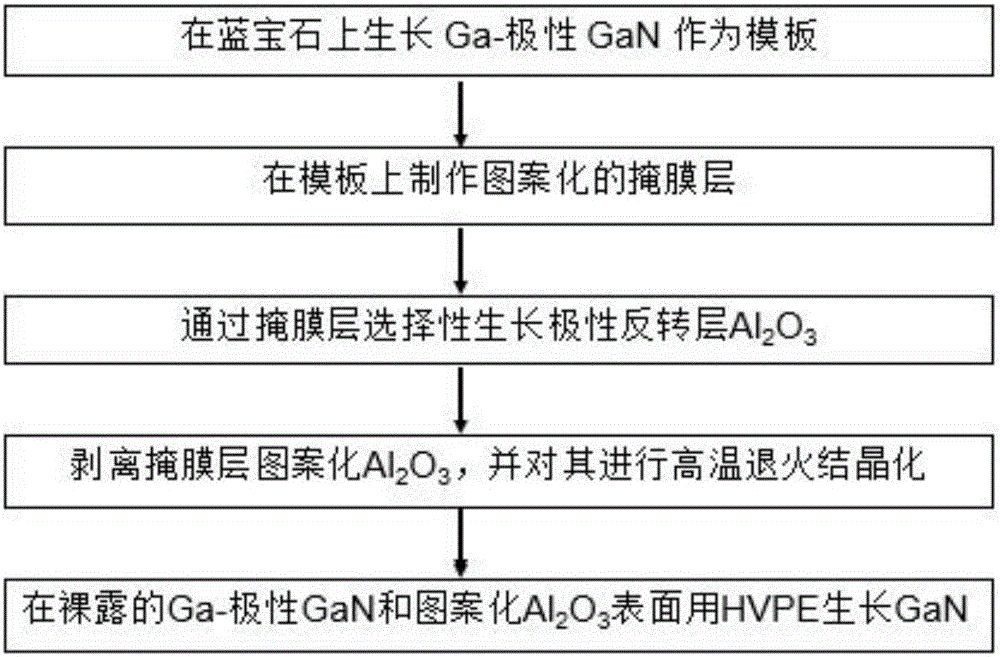

[0044] Methods for growing alternating N- and Ga-polar GaN structures on sapphire substrates:

[0045] Step 1: Clean the sapphire substrate with isopropanol, acetone, methanol, alcohol, and deionized water at room temperature for 5 minutes, and finally wash it with N 2 blow dry.

[0046] Step 2: Put the cleaned sapphire substrate in the MOCVD reaction chamber, using triethylgallium TEG and NH 3 As a source, Ga-polar GaN with a film thickness of 1.5-2um is grown under conditions of a temperature of 1100°C, a chamber pressure of 150Torr, and a V / III ratio of 600-3000. ;

[0047] Step 3: Using the Ga-polar GaN layer as a template, prepare a patterned mask layer PVP: soak the above sample in deionized water for 2 minutes, and then use 80°C standard cleaning solution SC1 (NH 4 0H:H 2 o 2 :H 2 (O=1:1:5) wash for 10 minutes, then wash with deionized water and blow dry with nitrogen, then spin-coat PVP with a thickness between 0.1-1um on a glue coater, and then put it in an oven...

Embodiment 2

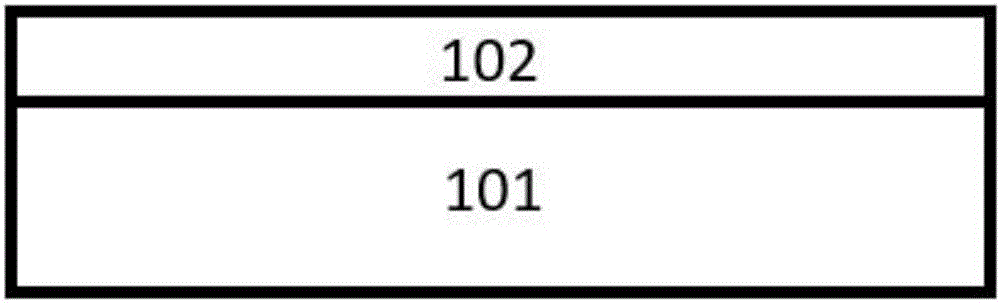

[0052] 1) Refer to figure 2 , the sapphire substrate 101 was ultrasonically cleaned with isopropanol, acetone, methanol, and alcohol at room temperature for 5 minutes, then repeatedly rinsed with deionized water, and washed with N 2 blow dry. Place the cleaned sapphire substrate 101 in the MOCVD reaction chamber, using triethylgallium TEG and NH 3 As a source material, a 2um Ga-polar GaN layer 102 was grown under conditions of a temperature of 1100° C., a chamber pressure of 150 Torr, and a V / III ratio of 3000.

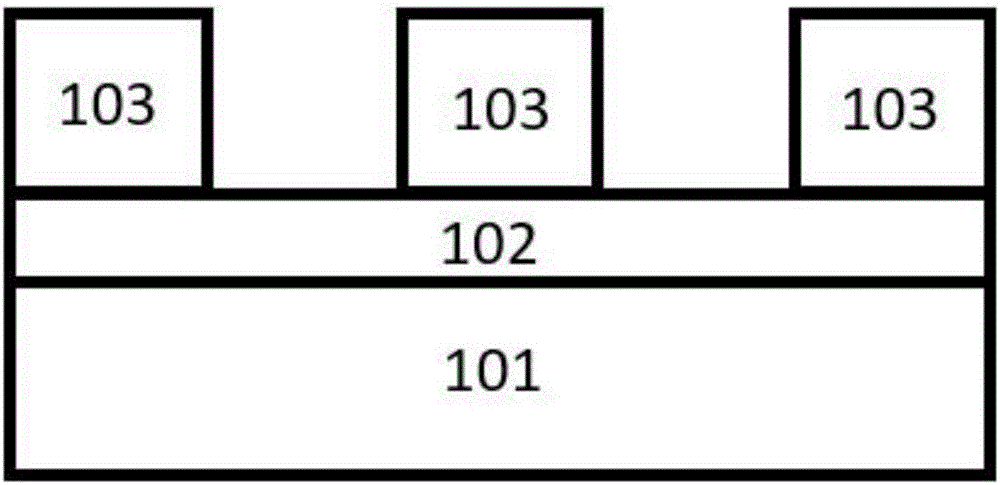

[0053] 2) Refer to image 3 , using the Ga-polar GaN layer 102 as a template to prepare a patterned mask layer PVP 103: first soak the sample in the previous step in deionized water for 2 minutes, and then use 80°C standard cleaning solution SC1 (NH40H: H2O2:H2O=1:1:5) for 10 minutes, then rinsed with deionized water and blown dry with nitrogen, then put PVP with a thickness of 100nm on a glue coater, and then baked in an oven at 100°C for 60 Minutes, the dried P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com