Flake NiXP/Ni negative electrode material for sodium-ion battery and preparation method of flake NiXP/Ni negative electrode material

A sodium ion battery and negative electrode material technology, applied in the field of electrochemistry, can solve the problems of harming human health, high cost, high temperature, etc., and achieve the effects of improving cycle life, good electrical contact performance, and alleviating volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

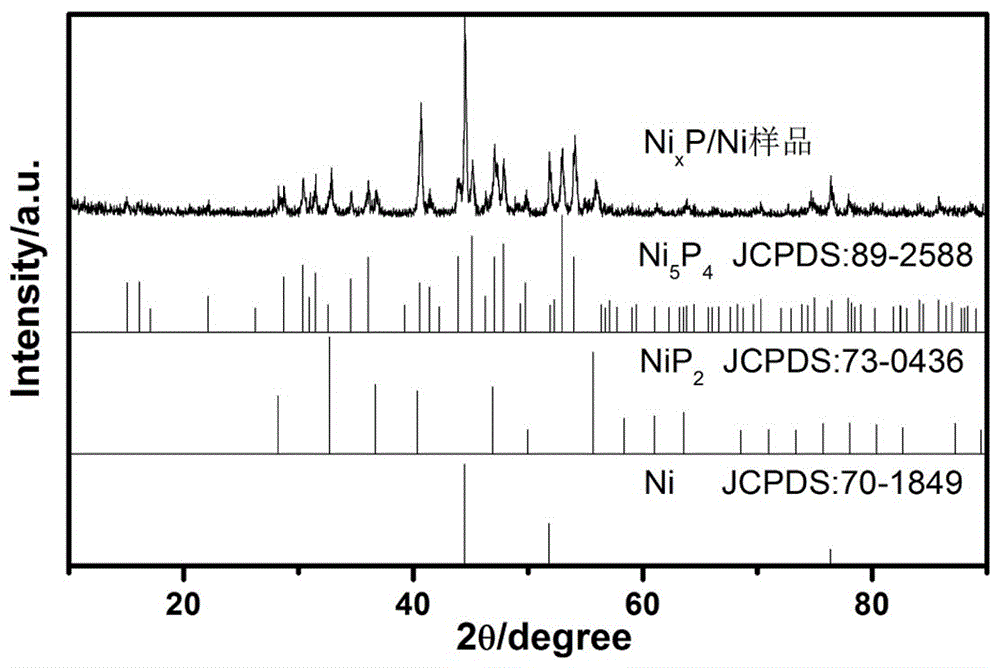

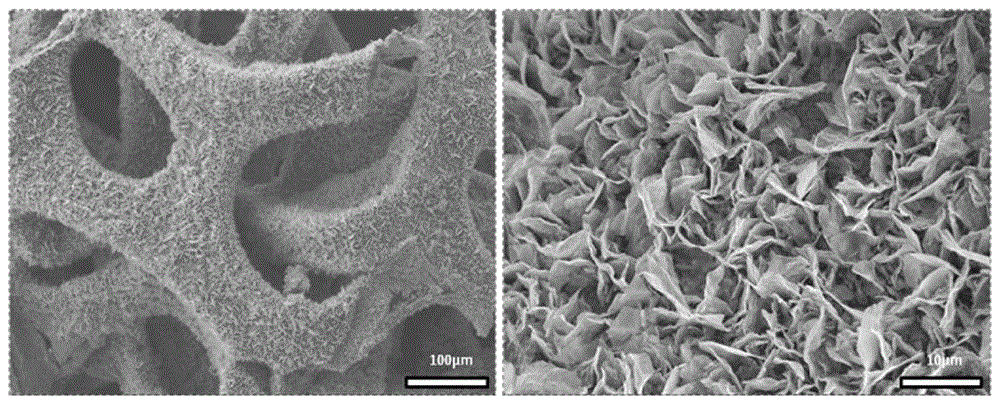

[0019] Example 1: Take 0.15 g of red phosphorus, put it into a steel reaction kettle, then put it into a round nickel foam, fill it with an argon atmosphere, and seal the reaction kettle. The steel reaction kettle was put into a muffle furnace and heated to 400°C, and kept for 3 hours, then cooled to room temperature, and the nickel foam was taken out. The electrode preparation method, battery assembly and test conditions are the same as those of the comparative example. The inclusion of Ni, NiP can be confirmed by X-ray diffraction characterization 2 and Ni 5 P 4 crystals, synthesized Ni X P / Ni composite material. Electrochemical performance test shows that the first discharge capacity is 0.6mAh / cm 2 , the discharge capacity after 60 cycles is 0.2 mAh / cm 2 , The capacity retention rate was 33.3%. It shows that in the sealed state, the red phosphorus in the gas phase reacts fully with the nickel foam matrix, and the discharge capacity is significantly improved.

Embodiment 2

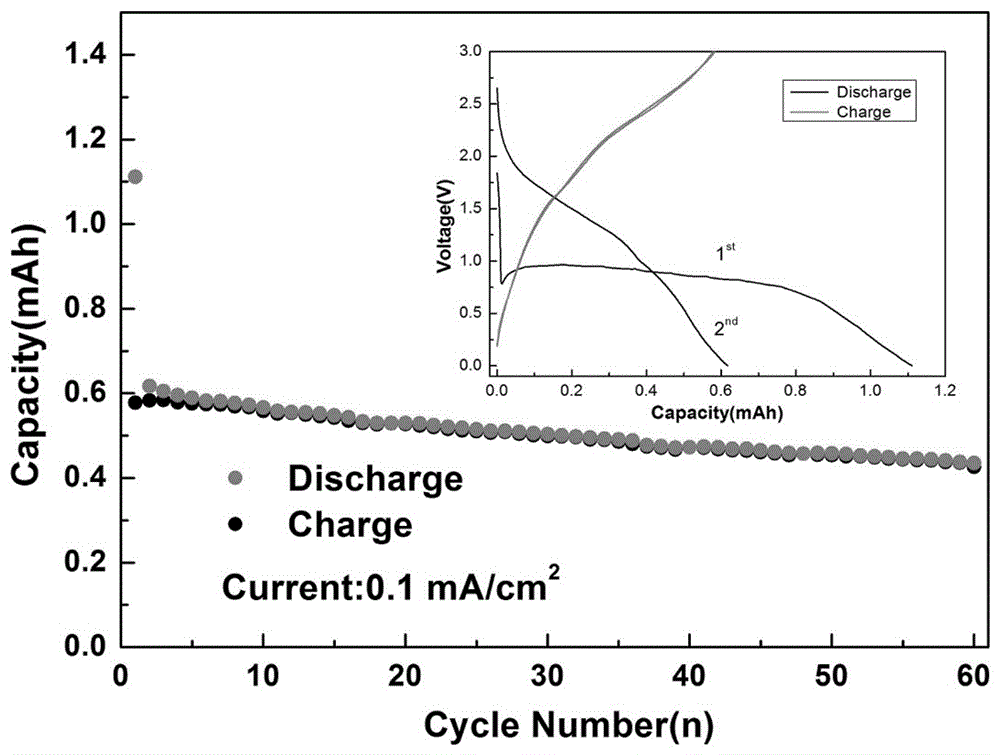

[0020] Example 2: Take 0.15 g of red phosphorus, put it into a steel reaction kettle, then put it into a circular nickel foam in turn, fill it with an argon atmosphere, and seal the reaction kettle. Put the steel reaction kettle into the muffle furnace and heat it to 500°C, then keep it warm for 5 hours, then cool it down to room temperature, and take out the nickel foam. The electrode preparation method, battery assembly and test conditions are the same as those of the comparative example. The inclusion of Ni, NiP can be confirmed by X-ray diffraction characterization 2 and Ni 5 P 4 crystals, synthesized Ni X P / Ni composite material. Electrochemical performance test shows that the first discharge capacity is 0.72mAh / cm 2 , the capacity after 60 cycles is 0.28 mAh / cm 2 , The capacity retention rate is 70.5%. It shows that in the airtight state, the increase of temperature and the increase of holding time promote the reaction of red phosphorus in the gas phase state and ...

Embodiment 3

[0024] Example 3: Take 0.15 g of red phosphorus and put it into a steel reaction kettle, then put it into a circular nickel foam in turn, fill it with an argon atmosphere, and seal the reaction kettle. Put the steel reaction kettle into a muffle furnace and heat it to 600°C, then keep it warm for 7 hours, then cool it down to room temperature, and take out the nickel foam. The electrode preparation method, battery assembly and test conditions are the same as those of the comparative example. The inclusion of Ni, NiP can be confirmed by X-ray diffraction characterization 2 and Ni 5 P 4 crystal, synthesized Ni X P / Ni composite material. Electrochemical performance test shows that the first discharge capacity is 0.50mAh / cm 2 , the capacity after 60 cycles is 0.15 mAh / cm 2 , The capacity retention rate is 30%. If the temperature is too high and the time is too long, the material will be agglomerated, and the electrical contact effect between the formed phosphide and the foa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com