Soluble granule for preventing and treating root disease and application method thereof

A technology for root diseases and application methods, applied in the field of compound pesticides and soluble granules, can solve the problems of reduced insecticidal activity, decomposition and oxidation of effective components, easy moisture return, etc., to expand the scope of application, improve the control effect and production cost. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

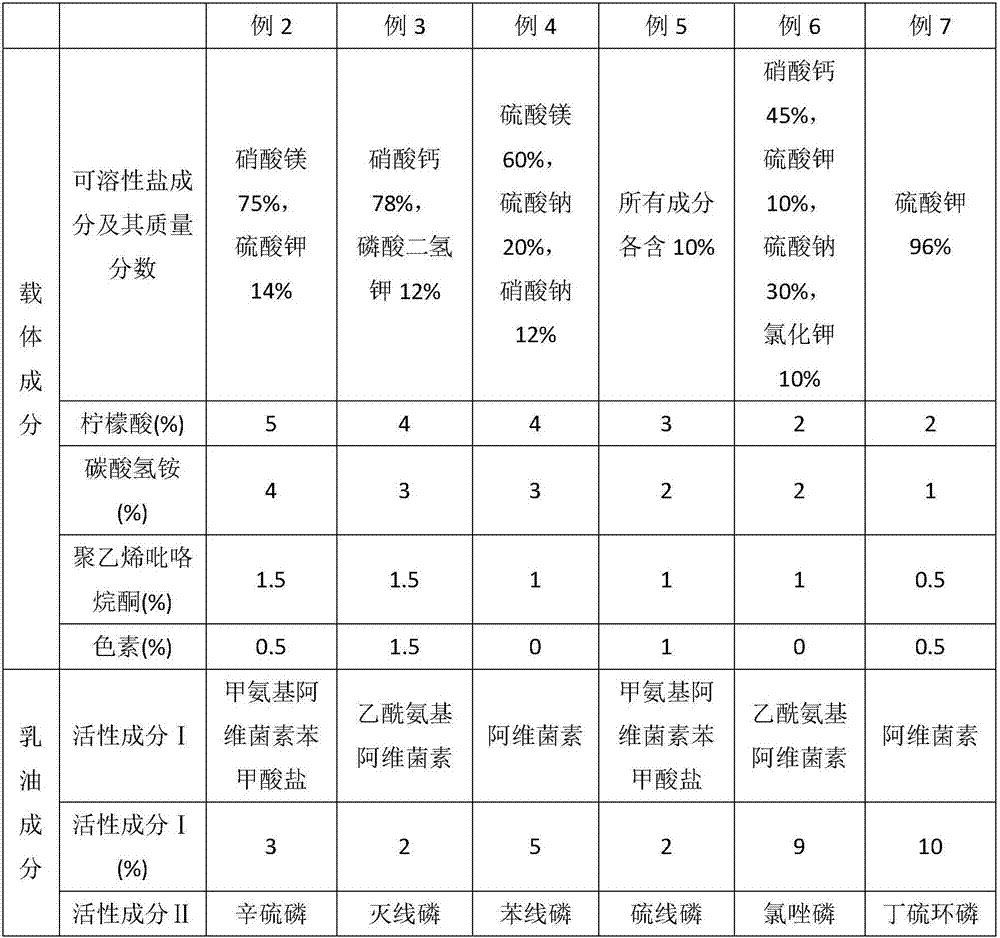

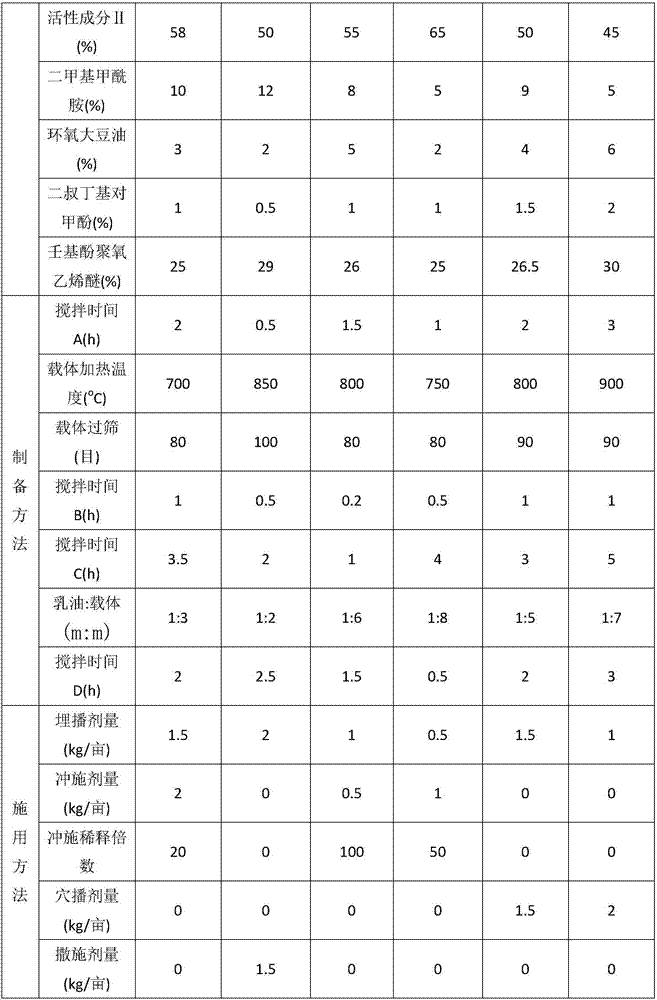

preparation example Construction

[0039] The preparation method steps of the soluble granule for preventing and treating root diseases are as follows:

[0040] Prepare the carrier: put the carrier raw materials into the mixing tank, mix and stir for 0.5-3 hours, then pour into the high-temperature furnace, continue to stir and heat to 700-900°C, after the raw materials reach the molten state, ventilate and cool until they are completely solidified, then put them into the pulverizer Pulverize and pass through 80-100 mesh sieves to obtain the carrier.

[0041] Preparation of emulsifiable concentrate: first add active ingredient I to dimethylformamide, then add di-tert-butyl-p-cresol, stir with a stirring tank until completely dissolved, then add active ingredient II, stir for 0.2 to 1 hour, then add ring Oxygenated soybean oil, finally adding nonylphenol polyoxyethylene ether, stirring for 1 to 5 hours to form an emulsifiable concentrate.

[0042] Preparation of soluble granules: Put the prepared emulsifiable c...

Embodiment 1

[0045] Soluble granules for preventing and treating root diseases are composed of a carrier and an emulsifiable concentrate. The raw material of the carrier and its mass fraction in the carrier are 70% of magnesium sulfate, 16% of sodium sulfate, 6% of citric acid, and 6% of ammonium bicarbonate. 5%, polyvinylpyrrolidone contains 2%, pigment contains 1%. The raw material of the emulsifiable concentrate and its mass fraction in the emulsifiable concentrate are 2% of abamectin, 50% of thiazolylphosphine, 12% of dimethylformamide, 2% of epoxidized soybean oil, and 2% of di-tert-butyl p-cresol Containing 0.5%, nonylphenol polyoxyethylene ether containing 29%.

[0046] The preparation method of this soluble granule is:

[0047] Preparation of the carrier: Put the above-mentioned carrier raw materials into a stirring tank, mix and stir for 1 hour, then pour into a high-temperature furnace, continue to stir and heat to 800°C, after the raw materials reach a molten state, ventilate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com