High-speed spraying aluminum profile fluorocarbon powder formula and spraying method

An aluminum profile, high-speed technology, applied in powder coatings, coatings, polyurea/polyurethane coatings, etc., can solve problems such as poor adhesion, increased wastewater discharge, and poor performance, and achieve low cost and reduced construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

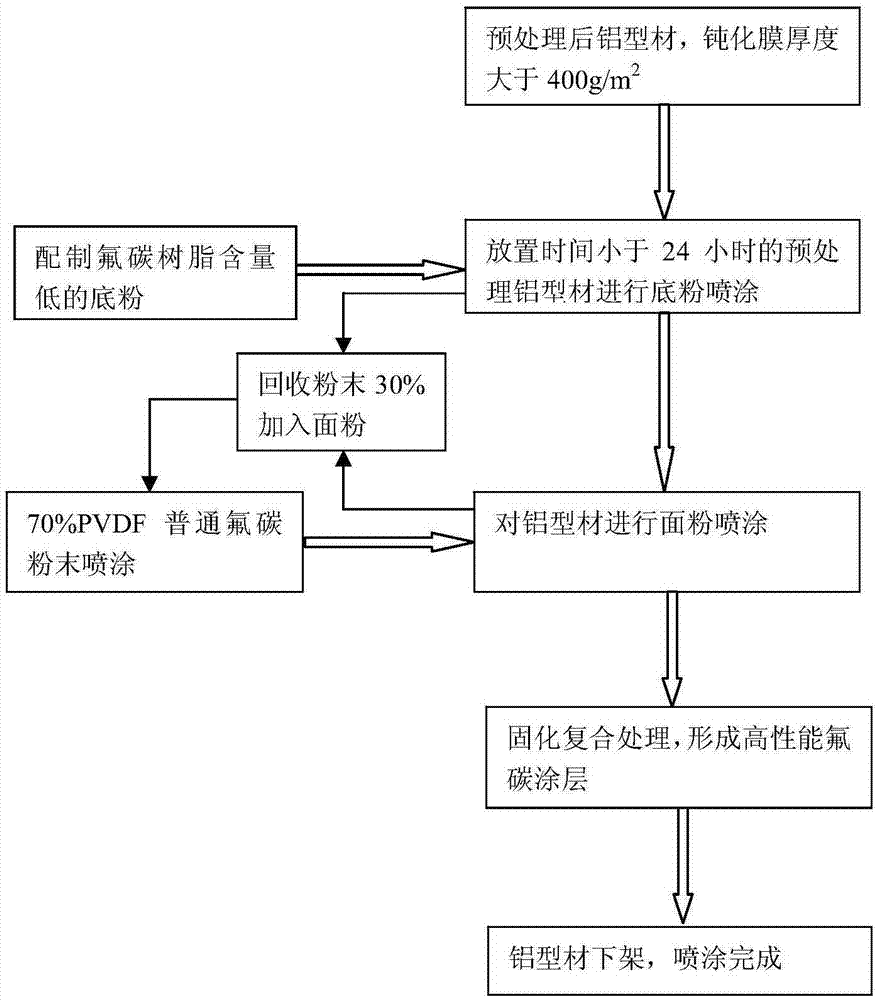

Method used

Image

Examples

Embodiment 1

[0033] In this example, first make 10kg of fluorocarbon powder as a base powder, and its composition quality is 90g of PVDF fluorocarbon resin, 3300g of acrylic acid, 400g of polyisocyanate, 6000g of polyester resin, 60g of benzoin, and 150g of leveling agent. Mix them evenly and extrude Manufactured into fine powder. The aluminum profile to be sprayed is pretreated by passivation process. The pretreatment process is: degreasing with sulfuric acid, the concentration of the bath solution is 150g / L, and the treatment time is 8 minutes; washing with water for 2 minutes; alkaline etching, the concentration of the bath solution is 15g / L, Treatment time is 6 minutes; water washing for 2 minutes; neutralization, bath concentration 150g / L, treatment time 8 minutes; water washing 2 minutes; acid degreasing, acidity 6, treatment time 4 minutes; pure water washing, pure water conductivity 60μs / cm , treatment time 2 minutes; passivation, cell index 6.2, PH value 1.6, treatment time 5 minu...

Embodiment 2

[0035] The bottom powder used in this embodiment is the same as that in Example 1, the flour 2 used is made up of 30% recycled powder and 70% new powder, the forward speed of the aluminum profile is 4.5m / min, the pretreatment process and spraying process are the same as in Example 1, After spraying, the average thickness of the total coating on the surface of the profile is 45µm, and the appearance quality and performance of the profile are good.

Embodiment 3

[0037]In this example, first make 10kg of fluorocarbon powder as a base powder, and its composition quality is 100g of PVDF fluorocarbon resin, 4500g of acrylic acid, 400g of polyisocyanate, 4800g of polyester resin, 50g of benzoin, and 150g of leveling agent. After mixing evenly, extrude Manufactured into fine powder. Use passivation process to pre-treat the aluminum profiles to be sprayed. The pre-treatment process is: degreasing with sulfuric acid, the concentration of the bath solution is 220g / L, and the treatment time is 2 minutes; washing with water for 4 minutes; alkali etching, the concentration of the bath solution is 25g / L, Treatment time is 2 minutes; water washing for 8 minutes; neutralization, bath index 220g / L, treatment time 3 minutes; water washing 6 minutes; acid degreasing, acidity 12, treatment time 2 minutes; pure water washing, pure water conductivity 80μs / cm , treatment time 2 minutes; passivation, tank index 15, PH value 2.2, treatment time 2 minutes; pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com