Ultrathin Ni-Co stratified-structure hydroxide as well as preparation method and application thereof

A layered structure and hydroxide technology, which is applied in the manufacture of cobalt oxide/cobalt hydroxide, nickel oxide/nickel hydroxide, hybrid/electric double layer capacitors, etc., can solve the problems of complicated process and harsh reaction conditions, and achieve The effect of simple process route and excellent capacitance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

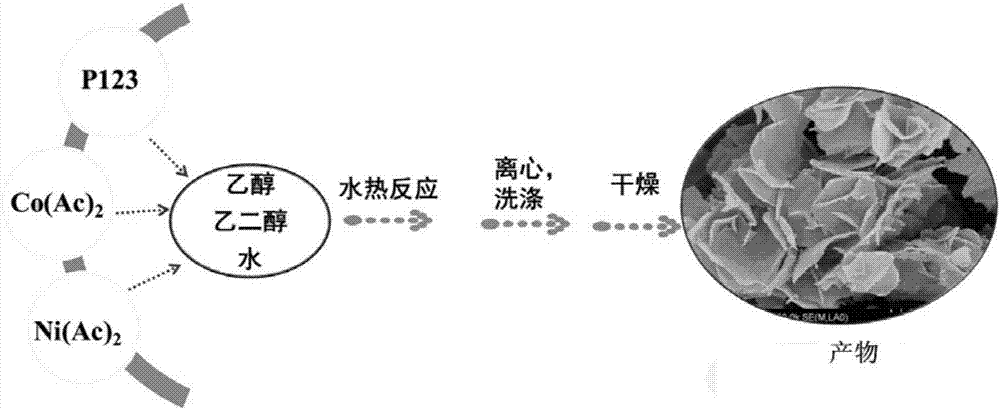

[0025] According to a specific embodiment of the present invention, the preparation method includes the following steps.

[0026] Step A:

[0027] Ni(Ac) 2 4H 2 O and Co(Ac) 2 4H 2 O and hexamethylenetetramine were added to distilled water, then absolute ethanol and ethylene glycol dissolved in P123 were added in sequence, and stirred until all raw materials were completely dissolved to obtain a mixed solution.

[0028]This step mainly involves dissolving the raw materials, dissolving and mixing the solid raw materials with the solvent and the structure directing agent to form a mixed solution. Among them, Co(Ac) 2 4H 2 O and Ni(Ac) 2 4H 2 O is used as cobalt source and nickel source respectively, and hexamethylenetetramine is slowly released by hydrolysis and provides OH - Cobalt ions and nickel ions are precipitated, P123 and ethylene glycol are used as structure-directing agents, and ethanol and water together form a mixed solvent. P123 and ethylene glycol as stru...

Embodiment 1

[0045] Embodiment 1: the addition of P123 is 0.2g

[0046] 1) Take 0.25g Ni(Ac) 2 4H 2 O and 0.50g Co(Ac) 2 4H 2 O and 1.68g of hexamethylenetetramine were added to 4mL of distilled water, then 40mL of absolute ethanol containing 0.2g of P123 and 30mL of ethylene glycol were added successively, and stirring was continued until all the raw materials were completely dissolved to obtain a mixed solution.

[0047] 2) The mixed solution was transferred to a 100 mL autoclave, and the temperature was gradually raised from room temperature to 170° C. under the condition of stirring, and the reaction was stirred at 170° C. for 2 h. Then, take out the obtained reaction liquid after it is naturally cooled to room temperature under the condition of stirring.

[0048] 3) Centrifuge the reaction solution (8000rmp) to separate the precipitate, wash it repeatedly with secondary water and absolute ethanol in turn, and dry the washed precipitate in a blast drying oven at 60°C for at least 1...

Embodiment 2

[0051] Embodiment 2: the addition of P123 is 0.5g

[0052] 1) Take 0.25g Ni(Ac) 2 4H 2 O and 0.50g Co(Ac) 2 4H 2 O and 1.68g of hexamethylenetetramine were added to 4mL of distilled water, then 40mL of absolute ethanol in which 0.5g of P123 was dissolved, and 30mL of ethylene glycol were added successively, and stirring was continued until all the raw materials were completely dissolved to obtain a mixed solution.

[0053] 2) The mixed solution was transferred to a 100 mL autoclave, and the temperature was gradually raised from room temperature to 170° C. under the condition of stirring, and the reaction was stirred at 170° C. for 2 h. Then, take out the obtained reaction liquid after it is naturally cooled to room temperature under the condition of stirring.

[0054] 3) Centrifuge the reaction solution (8000rmp) to separate the precipitate, wash it repeatedly with secondary water and absolute ethanol in turn, and dry the washed precipitate in a blast drying oven at 60°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com