Method for preparing SiO2-cellulose composite aerogel material with one-pot method

A composite airgel and cellulose technology, which is applied in the field of preparing SiO2-cellulose composite airgel materials by a one-pot method, can solve the problems of porosity reduction, blocking pore openings, cellulose phase separation, etc., and achieves practical results. Effective, simple process, and the effect of inhibiting phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

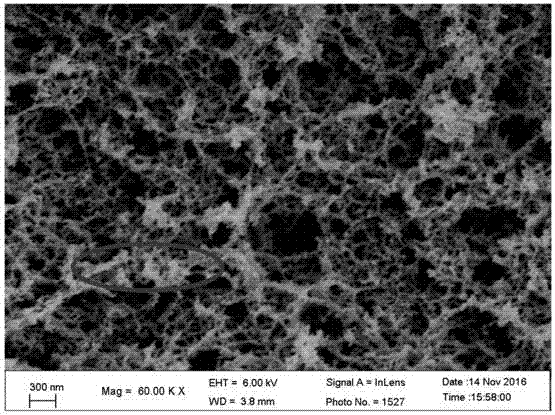

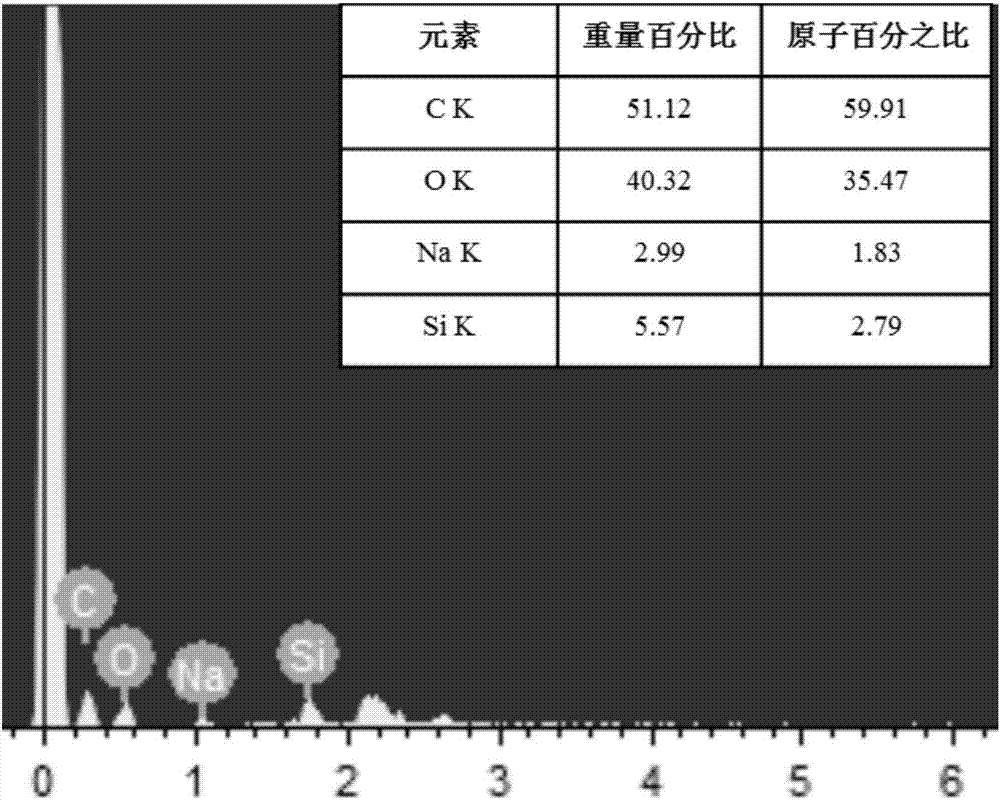

example 1

[0036] 1. Stir and disperse 2g of microcrystalline cellulose into alkali urea solution (4.0gLiOH / 10gUrea / 84gH 2 O), after dispersing, transfer to the refrigerator to pre-cool at -5°C, and immediately use the motor to stir at 2000 rpm for 4 minutes to dissolve the cellulose to obtain a viscous solution, and then immediately centrifuge at 8000 rpm for 10 minutes to remove bubbles Obtain a clear and transparent cellulose solution with a solvent mass fraction of 2%; weigh 16.3g of Na 2 SiO 3 ·9H 2 O was dissolved in 83.7g of distilled water with magnetic stirring to obtain a 7% sodium silicate aqueous solution. The cellulose solution and sodium silicate solution were mechanically stirred and mixed at a volume ratio of 10:1, and then ultrasonically oscillated to remove bubbles to form a uniform solution. Mixed sodium silicate-cellulose mixed solution. Then, the uniformly mixed sodium silicate-cellulose mixed solution is poured into the mold and placed in a methanol coagulation bath f...

example 2

[0038] Stir and disperse 6g cotton pulp cypress cellulose into alkali urea solution (4gLiOH / 10gThiourea / 80gH 2 O), transfer to the refrigerator to pre-cool at -20°C after dispersing, immediately use the motor to stir for 4 minutes at 2000 rpm to dissolve the cellulose to obtain a viscous solution, and then immediately centrifuge at 10000 rpm for 5 minutes to remove bubbles Obtain a clear and transparent cellulose solution with a solvent mass fraction of 6%; weigh 1.74g of Na 2 SiO 3 ·5H 2 O is dissolved in 98.3g of distilled water with magnetic stirring to obtain a 1% sodium silicate aqueous solution. The cellulose solution and sodium silicate solution are mechanically stirred and mixed in a volume ratio of 1:1, and the bubbles are removed by ultrasonic vibration to form a uniform mixture. The sodium silicate-cellulose mixed solution. Then, the uniformly mixed sodium silicate-cellulose mixed solution is poured into the mold and placed in an ethanol coagulation bath for regenerat...

example 3

[0040] Stir and disperse 3g of linter cotton cellulose into alkali urea solution (of which 4.6gNaOH / 15gUrea / 77.4gH 2 O), transfer to the refrigerator to pre-cool at -15°C after dispersing, immediately use the motor to stir for 12 minutes at 1000 rpm to dissolve the cellulose to obtain a viscous solution, and then immediately centrifuge at 8000 rpm for 10 minutes to remove bubbles Obtain a clear and transparent cellulose solution with a solvent mass fraction of about 3%; weigh 3g of anhydrous Na 2 SiO 3 Dissolve into 97ml of distilled water with magnetic stirring to obtain a 3% sodium silicate aqueous solution. The cellulose solution and sodium silicate solution are mechanically stirred and mixed in a volume ratio of 2:1, and the bubbles are removed by ultrasonic vibration. Uniformly mixed sodium silicate-cellulose mixed solution. Then pour the uniformly mixed sodium silicate-cellulose mixed solution into a mold and place it in an acetone coagulation bath for regeneration. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com