Automotive starter carbon brush material and preparation method thereof

A carbon brush, silicon carbide technology, applied in brush manufacturing, current collectors, rotary current collectors, etc., can solve the problem of insufficient hardness and flexural strength of carbon brush materials, adverse effects of electrical conductivity of composite materials, motor operation and stable replacement. It can improve the interface bonding ability, improve the friction and wear performance, and improve the hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

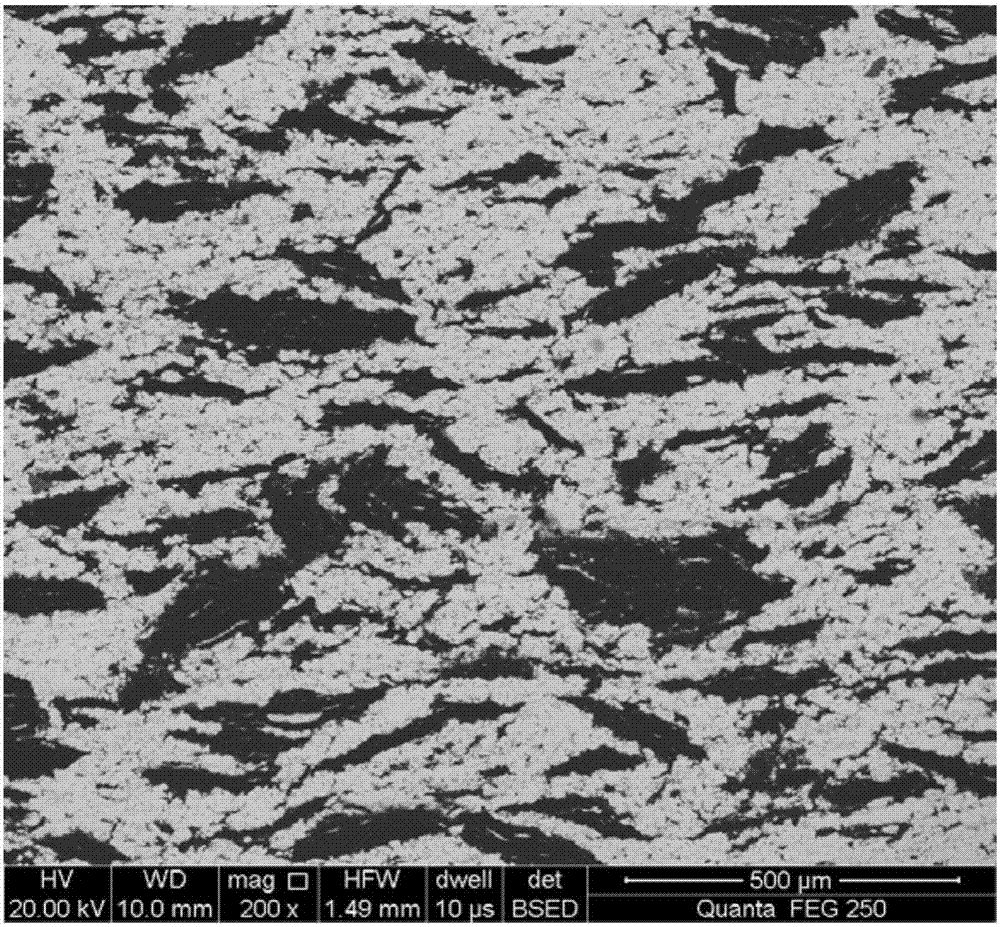

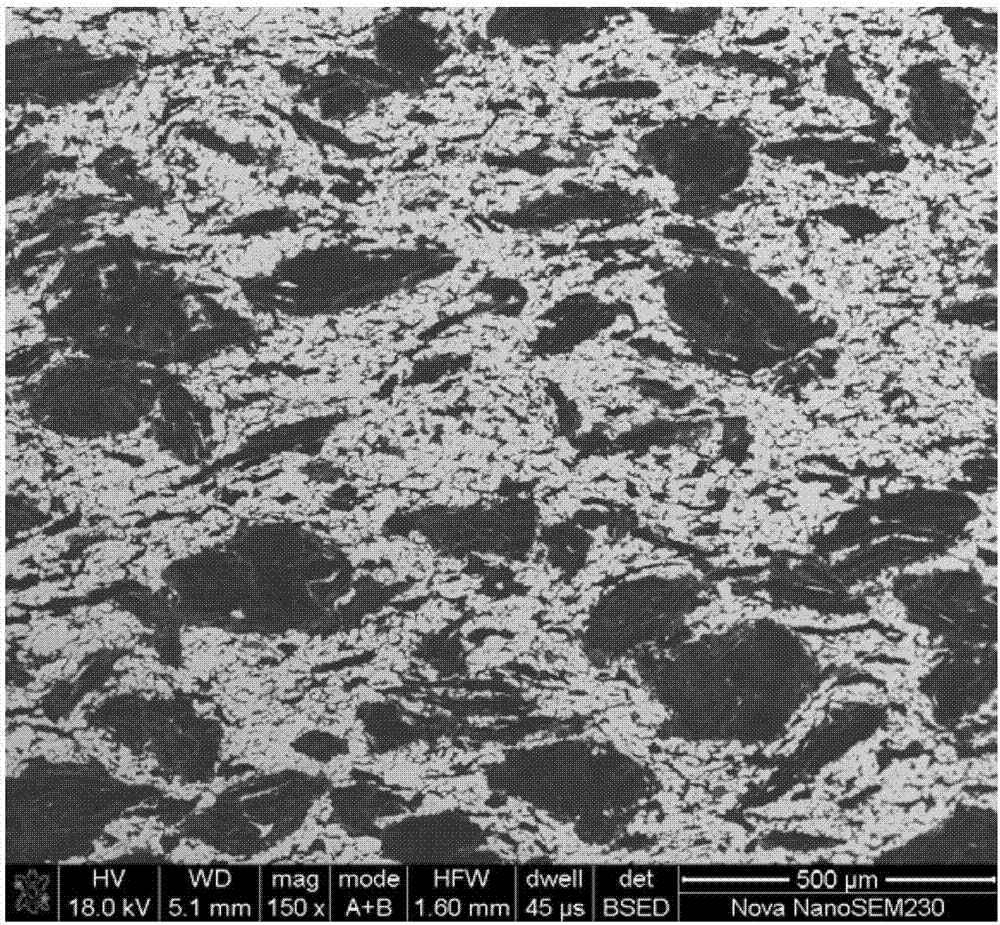

Image

Examples

preparation example Construction

[0088] The specific embodiment part of the present invention provides a kind of preparation method of carbon brush material, described method comprises:

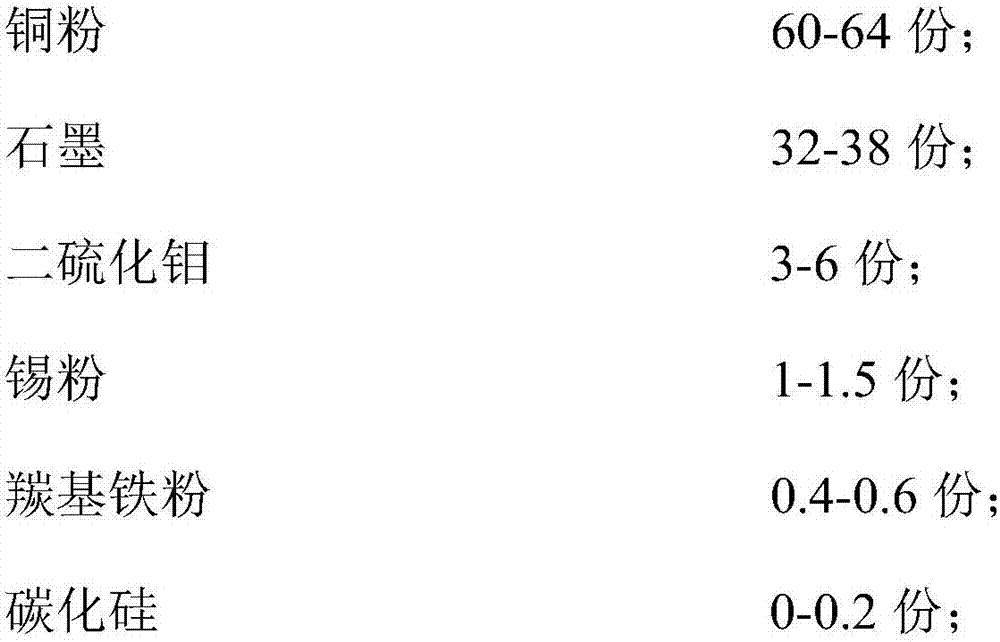

[0089] Dosing according to the following components:

[0090] Copper powder 60-64 parts; graphite 32-38 parts; molybdenum disulfide 3-6 parts; tin powder 1-1.5 parts; carbonyl iron powder 0.4-0.6 parts; silicon carbide 0-0.2 parts; silicon dioxide 0-0.2 parts ; 0-0.5 parts of silicon; the graphite is composed of fine graphite and colloidal graphite in a mass ratio (0.66-1.5): 1 matching composition.

[0091] Prepare carbon brushes as follows:

[0092] (1) each component is mixed according to formula quantity;

[0093] (2) pre-pressing the mixture obtained in step (1), sieving and granulating after crushing;

[0094] (3) The sample obtained after step (2) is sieved and granulated is pressed in a mould, and the blank is obtained after demoulding;

[0095] (4) Sintering the blank obtained in step (3) in a reducing atmospher...

Embodiment 1

[0098] Dosing according to the following components:

[0099] 63 parts of copper powder; 3 parts of molybdenum disulfide; 32 parts of graphite; 1 part of tin powder; 0.4 parts of carbonyl iron powder; 0.2 parts of silicon carbide; 0.1 parts of silicon dioxide; Match composition according to mass ratio 1:1.

[0100] Prepare carbon brushes as follows:

[0101] (1) Take copper powder, graphite, molybdenum disulfide, tin powder, carbonyl iron powder, silicon carbide, silicon dioxide and silicon according to the above-mentioned formula quantity for subsequent use, and mix the above-mentioned raw materials in a V-shaped mixer, adjust The rotating speed of the mixer is 35r / min, and the mixing time is 90min;

[0102] (2) Prepress the mixture obtained in step (1) for 3s under a pressure of 5Mpa, then crush and sieve and granulate to obtain a -50 mesh sample;

[0103] (3) Pour the sample after step (2) granulation into the steel mold, under the pressure of 150MPa, bidirectionally pre...

Embodiment 2

[0107] Dosing according to the following components:

[0108] 63 parts of copper powder; 6 parts of molybdenum disulfide; 38 parts of graphite; 1.5 parts of tin powder; 0.6 parts of carbonyl iron powder; 0.1 part of silicon carbide; 0.1 part of silicon dioxide; Match composition according to mass ratio 1:1.

[0109] Prepare carbon brushes as follows:

[0110] (1) Take copper powder, graphite, molybdenum disulfide, tin powder, carbonyl iron powder, silicon carbide, silicon dioxide and silicon according to the above-mentioned formula quantity for subsequent use, and mix the above-mentioned raw materials in a V-shaped mixer, adjust The rotating speed of the mixer is 45r / min, and the mixing time is 120min;

[0111] (2) pre-compress the mixture obtained in step (1) for 1s under a pressure of 10Mpa, then crush and sieve and granulate to obtain a -50 mesh sample;

[0112] (3) Pour the sample after step (2) granulation into the steel mold, under the pressure of 220MPa, bidirectiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com